- Messages

- 38

- Reaction score

- 132

- Arrma RC's

- Typhon 6s

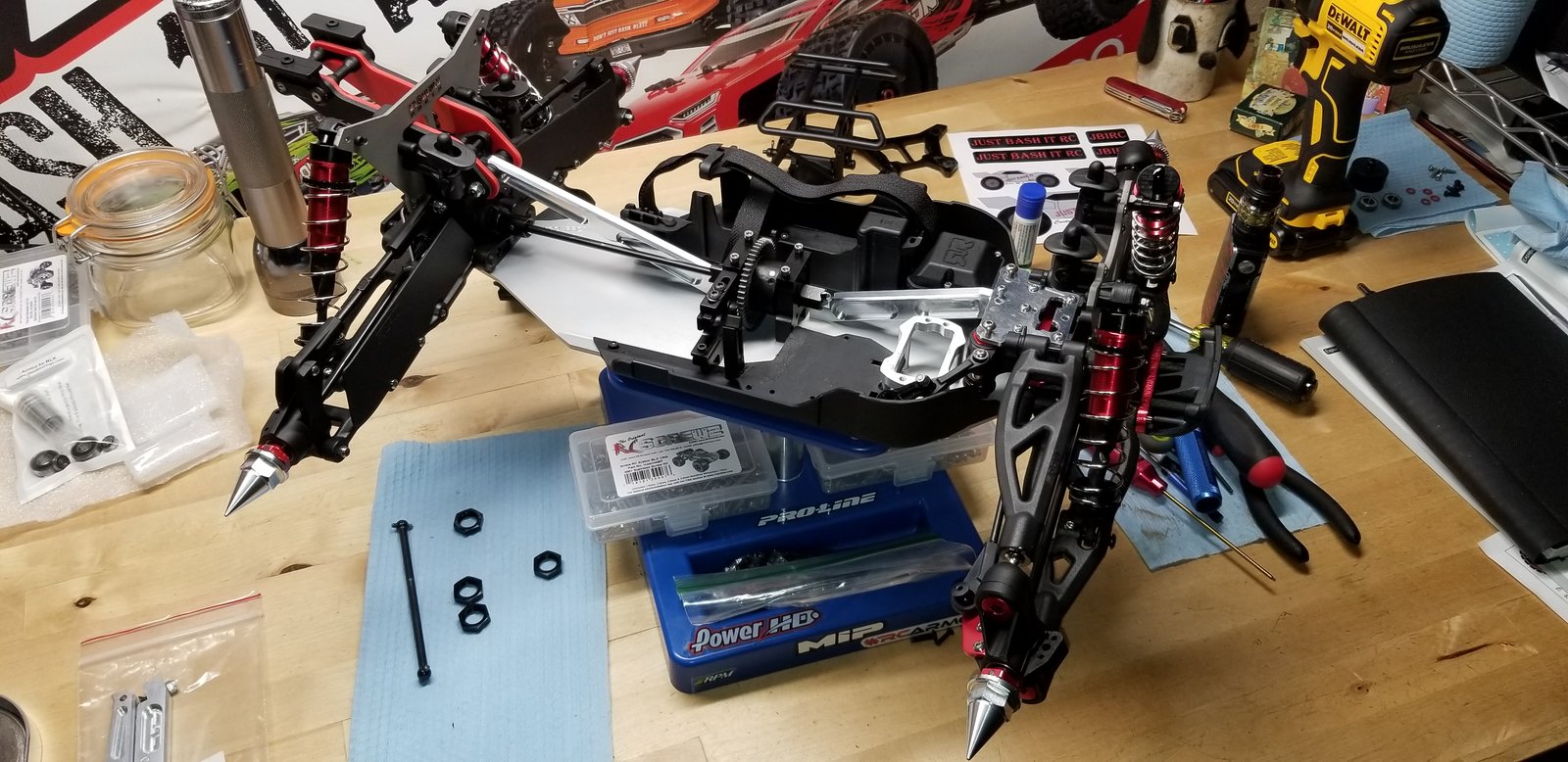

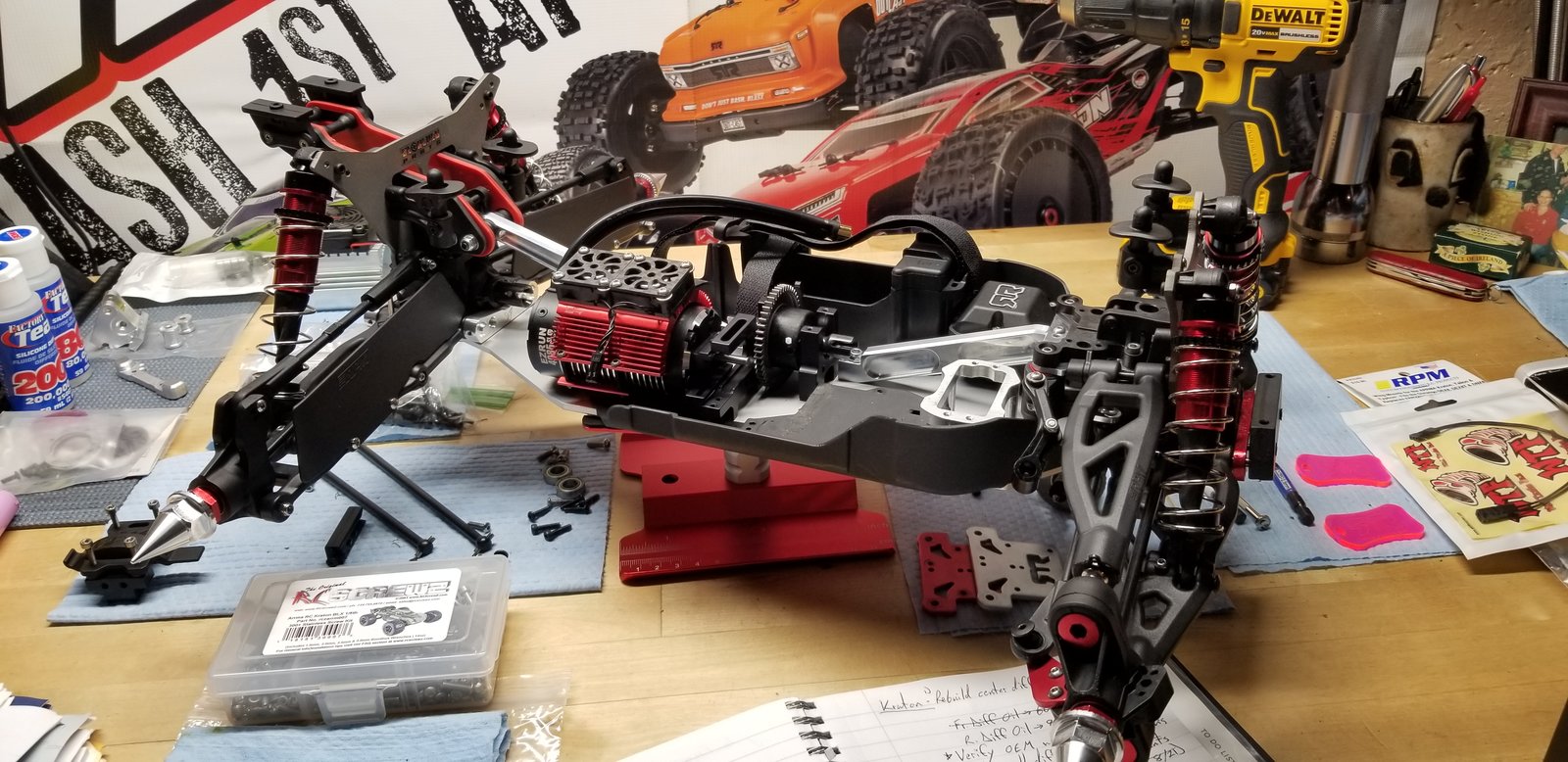

The short back story: have been into RC as a now and then hobby for a few years. Have always wanted an Arrma, and a buggy, and caught a great deal on a still brand new V2 Typhon 6s that I couldn't pass up. Immediately fell in love!

I've been wanting to do a build, but wasn't comfortable enough in my knowledge, but finally said screw it! After a bit of research, ended up going for a Kraton. Told my wife why I'd be getting packages for weeks/months and she simply said "I don't care what you do, so long as the bills get paid" Have I mentioned that I love her! haha She also said that she didn't want to know what it cost (thank God)

And so it began...

Parts List:

v4 Kraton 6s roller

M2c chassis

M2c motor mount

M2c skid plates front and rear (might not run with the TBone)

M2c droop screws

Voltage front and rear braces

Voltage rear suspension mounts

Voltage ackerman

Alza front suspension mounts

JBIRC servo plate

JBIRC wing/brace support

JBIRC servo mount

RPM arms all around

RPM mud guards

TBone wing mount

TBone front bumper

TBone wheelie bar

Amped carbon fiber center brace

ScorchedRC Titanium towers

Arrma metal diff cup for center

Jim's bearings kit

Hobbywing Max6 combo with the 1650

Tekno 20t pinion

YR dual fan heatsink

WTF 30mm fans x 2

Alza carbon fiber fan grills

**Savox SB-2292SG (waterproofed)

Typhon V4 wing

100/200/80 diff fluid

Spektrum DX5C w/6100 reciever

Yoga Matt added to battery tray (strongly recommend this as it helps with the batteries)

I think that rounds it out, but sure I'm forgetting something.

I'll post more pictures and some areas that I got hung up on when I can. Will also continue to update this thread as the build SLOWLY progresses (not a lot of free time).

So far I'm extremely happy with the way this build is coming along and I think it's making for one badass Kraton (The Kraken)

**Edit: forgot the servo, so added it in

I've been wanting to do a build, but wasn't comfortable enough in my knowledge, but finally said screw it! After a bit of research, ended up going for a Kraton. Told my wife why I'd be getting packages for weeks/months and she simply said "I don't care what you do, so long as the bills get paid" Have I mentioned that I love her! haha She also said that she didn't want to know what it cost (thank God)

And so it began...

Parts List:

v4 Kraton 6s roller

M2c chassis

M2c motor mount

M2c skid plates front and rear (might not run with the TBone)

M2c droop screws

Voltage front and rear braces

Voltage rear suspension mounts

Voltage ackerman

Alza front suspension mounts

JBIRC servo plate

JBIRC wing/brace support

JBIRC servo mount

RPM arms all around

RPM mud guards

TBone wing mount

TBone front bumper

TBone wheelie bar

Amped carbon fiber center brace

ScorchedRC Titanium towers

Arrma metal diff cup for center

Jim's bearings kit

Hobbywing Max6 combo with the 1650

Tekno 20t pinion

YR dual fan heatsink

WTF 30mm fans x 2

Alza carbon fiber fan grills

**Savox SB-2292SG (waterproofed)

Typhon V4 wing

100/200/80 diff fluid

Spektrum DX5C w/6100 reciever

Yoga Matt added to battery tray (strongly recommend this as it helps with the batteries)

I think that rounds it out, but sure I'm forgetting something.

I'll post more pictures and some areas that I got hung up on when I can. Will also continue to update this thread as the build SLOWLY progresses (not a lot of free time).

So far I'm extremely happy with the way this build is coming along and I think it's making for one badass Kraton (The Kraken)

**Edit: forgot the servo, so added it in

Last edited: