Just a Basher

Active Member

- Messages

- 189

- Reaction score

- 377

- Location

- West Palm Beach, FL

- Arrma RC's

- Kraton 6s

- Senton 6s

- Talion

- Typhon 6s

It looks like the metal 4S spur gear will fit in a 3S rig with minor modifications.

Looking at the exploded views of the 4S slipper and the 3S slipper assembly, the part numbers are different. I took a gamble that ARRMA wouldn't change the design too much and the metal spur gear should drop right into my Senton.

It looks like there are two different slipper pads ARRMA is using. AR310790 is the octogon shaped pad and ARA310908 is the castellated slipper pad (I think this is the new 4S pad and my 3S senton has it too, so maybe a design update for the 3S line?). Looking at the spur gear, it looks like it will take either pad, but I can only say it works with the castellated pads.

Arrma part number ARA310945. It actually arrived before my Senton.

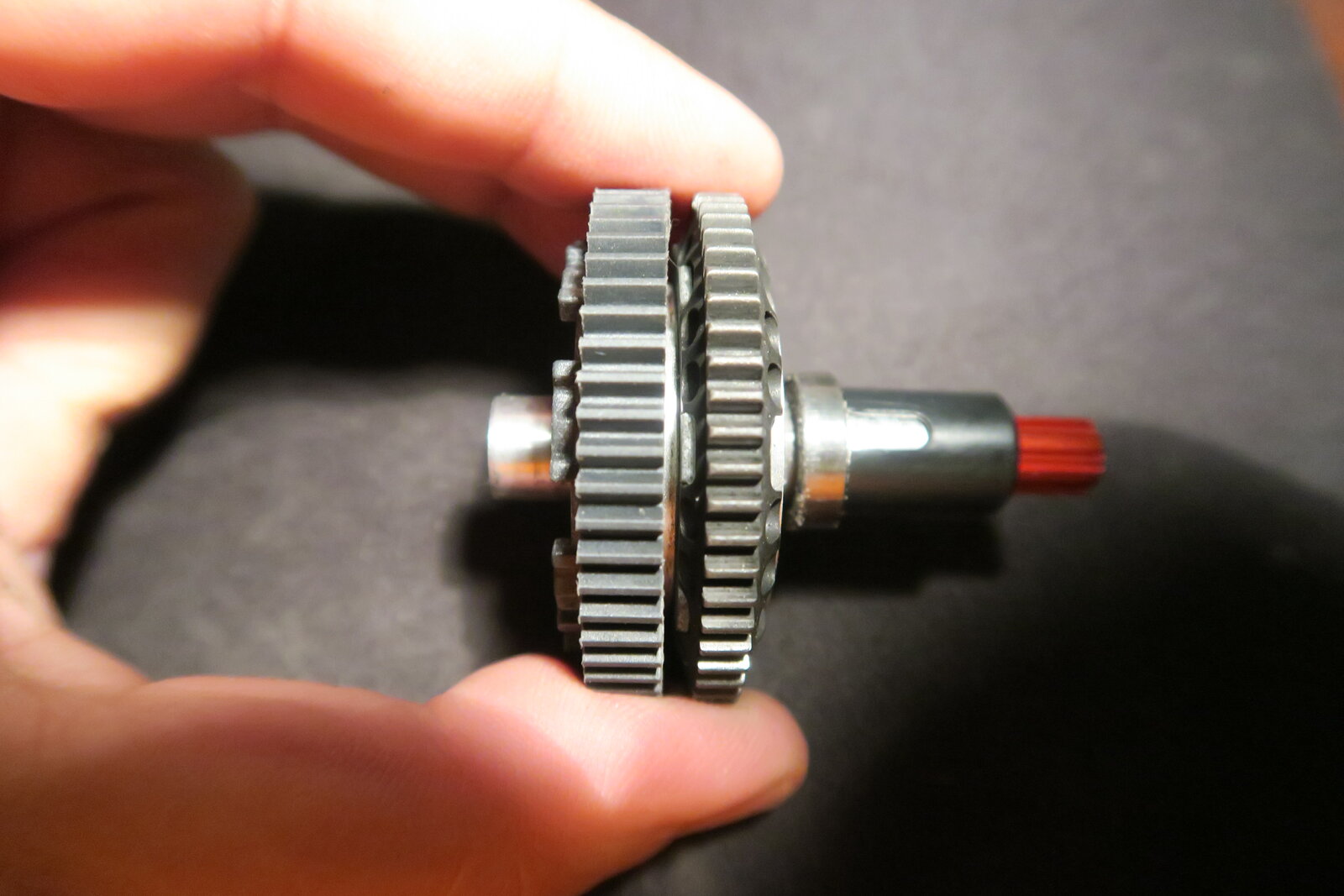

I should have taken pictures before I assembled the whole thing, but I thought of this too late. The right gear is the metal 4S spur gear mounted, and on the left is the stock 3S spur gear. The metal gear is quite a bit thinner than the original.

Left on both below is the metal gear mounted. Right is the original gear that was removed from the Senton.

The entire slipper assembly went together without any hiccups (aside from what seemed to be an entire tube of blue threadlocker holding everything together).

Dropping the slipper assembly into the motor housing is where I had to start modifying. The new gear doesn't sit in the same spot as the old gear, I had to trim a bit of the housing to ensure it would clear without any issue. I did notice when held the way it was in this picture, something seemed to contact the plastic motor housing (possibly part of the slipper assembly or spur gear since it sits further forward or downward in the photo than the original). That did not seem to be an issue since the spring in the driveshaft pushing the entire slipper assembly towards the rear of the car, or up in the photo below kept it away from whatever it may have been hitting.

I had to get creative here. The pinion and spur didn't line up and I had to push the pinion closer to the motor (down in the photo). Flipping the pinion doesn't work, it will interfere with the housing then. Simply pushing the pinion further down on the motor shaft meant I couldn't access the set screw to tighten the pinion. To access this, you need to loosen the screws attaching the motor to its mount, angle the motor so you can tighten set screw in the pinion, reattach the motor to its mount, and reassemble everything.

Everything should go back together and viola, a metal spur gear in a 3S Senton. It even sounds like its bigger 6S brothers.

Enjoy.

Looking at the exploded views of the 4S slipper and the 3S slipper assembly, the part numbers are different. I took a gamble that ARRMA wouldn't change the design too much and the metal spur gear should drop right into my Senton.

It looks like there are two different slipper pads ARRMA is using. AR310790 is the octogon shaped pad and ARA310908 is the castellated slipper pad (I think this is the new 4S pad and my 3S senton has it too, so maybe a design update for the 3S line?). Looking at the spur gear, it looks like it will take either pad, but I can only say it works with the castellated pads.

Arrma part number ARA310945. It actually arrived before my Senton.

I should have taken pictures before I assembled the whole thing, but I thought of this too late. The right gear is the metal 4S spur gear mounted, and on the left is the stock 3S spur gear. The metal gear is quite a bit thinner than the original.

Left on both below is the metal gear mounted. Right is the original gear that was removed from the Senton.

The entire slipper assembly went together without any hiccups (aside from what seemed to be an entire tube of blue threadlocker holding everything together).

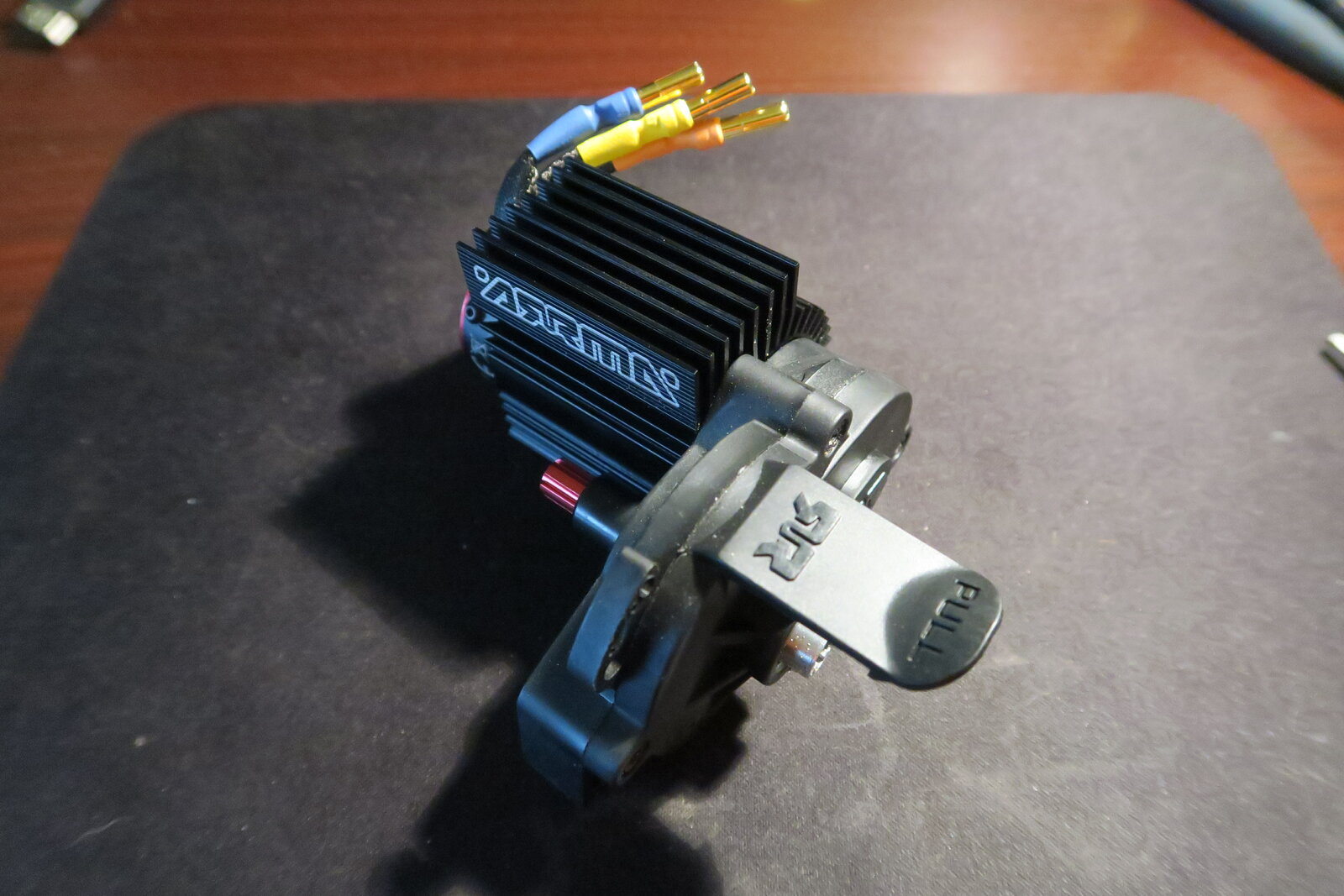

Dropping the slipper assembly into the motor housing is where I had to start modifying. The new gear doesn't sit in the same spot as the old gear, I had to trim a bit of the housing to ensure it would clear without any issue. I did notice when held the way it was in this picture, something seemed to contact the plastic motor housing (possibly part of the slipper assembly or spur gear since it sits further forward or downward in the photo than the original). That did not seem to be an issue since the spring in the driveshaft pushing the entire slipper assembly towards the rear of the car, or up in the photo below kept it away from whatever it may have been hitting.

I had to get creative here. The pinion and spur didn't line up and I had to push the pinion closer to the motor (down in the photo). Flipping the pinion doesn't work, it will interfere with the housing then. Simply pushing the pinion further down on the motor shaft meant I couldn't access the set screw to tighten the pinion. To access this, you need to loosen the screws attaching the motor to its mount, angle the motor so you can tighten set screw in the pinion, reattach the motor to its mount, and reassemble everything.

Everything should go back together and viola, a metal spur gear in a 3S Senton. It even sounds like its bigger 6S brothers.

Enjoy.