chaosmage

Fairly New Member

- Messages

- 26

- Reaction score

- 17

- Arrma RC's

- BigRock 4x4

Hi all,

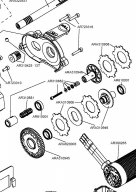

I'm an RC truck noob, just got a Big Rock on 3S, swapped a spur gear for "ARRMA HEAVY DUTY 57T SPUR GEAR 0.8MOD" and it killed everything inside after a few rides. I've tightened it pretty hard, as it was slipping all the time.

Now I see both bearings are gone, gear enclosure, pinion gear. I would appreciate if someone can help me to figure out how to fix that.

1. what did I do wrong?

2. what parts do I need to buy? and where do you usually get them?

- someone was recommending Robinson Racing Extra Hard Steel .8 Mod Pinion Gear w/5mm Bore (13T)

- Arrma 4x4 Composite Motor Mount Set

- no idea what bearings are those

3. it has chewed the center driveshaft too, but that was since the very beginning ...

Thanks a lot!!

P.S. I think I've got it. Tightened the slipper way too much, and here is the result.

I'm an RC truck noob, just got a Big Rock on 3S, swapped a spur gear for "ARRMA HEAVY DUTY 57T SPUR GEAR 0.8MOD" and it killed everything inside after a few rides. I've tightened it pretty hard, as it was slipping all the time.

Now I see both bearings are gone, gear enclosure, pinion gear. I would appreciate if someone can help me to figure out how to fix that.

1. what did I do wrong?

2. what parts do I need to buy? and where do you usually get them?

- someone was recommending Robinson Racing Extra Hard Steel .8 Mod Pinion Gear w/5mm Bore (13T)

- Arrma 4x4 Composite Motor Mount Set

- no idea what bearings are those

3. it has chewed the center driveshaft too, but that was since the very beginning ...

Thanks a lot!!

P.S. I think I've got it. Tightened the slipper way too much, and here is the result.

Attachments

Last edited: