Well I finally got my Kraton EXB the other day and started my build. My plan has always been a complete tear down to check everything, then rebuild it with all the upgrades I already have. Here is the full parts and upgrades list:

Day 1:

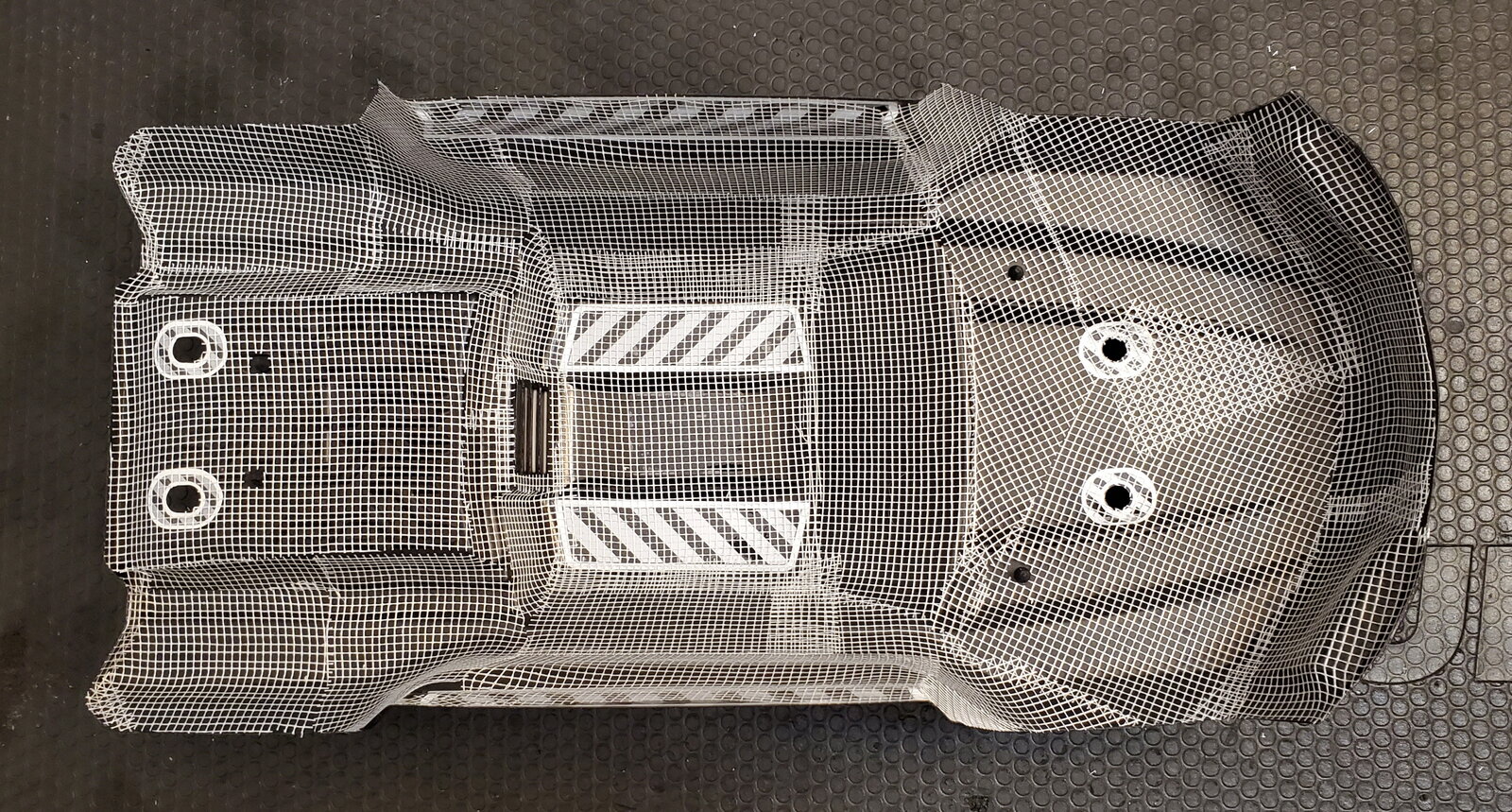

Technically I started the build before I had the new EXB because I had ordered a body and some other parts from Jennys that came before the new EXB did. So on Day 1 I started with reinforcing the body I had ordered with wall tape and Shoe Goo. The next day when I got the truck I did the second body. So these first pics are just both bodies reinforced with tape and glue. Both came out pretty good and are a lot stronger now.

Day 2:

To start Day 2 I did a much more thorough inspection of the truck and started the complete tear down. One of the first things I noticed was the diffs were pretty low. So I topped them off with the stock weight fluids. (10K F, 100K C, and 10K R). Im sure I will change these weights but just wanted to try it out first. I also found out that with the new style diffs you cant fill them as much. When I filled them like the manual shows (which is just like the old style) the fluids overflowed into the screw holes. So I took them back apart and took a bit of the fluids out. Im guessing this is due to the LSD plates taking up more room.

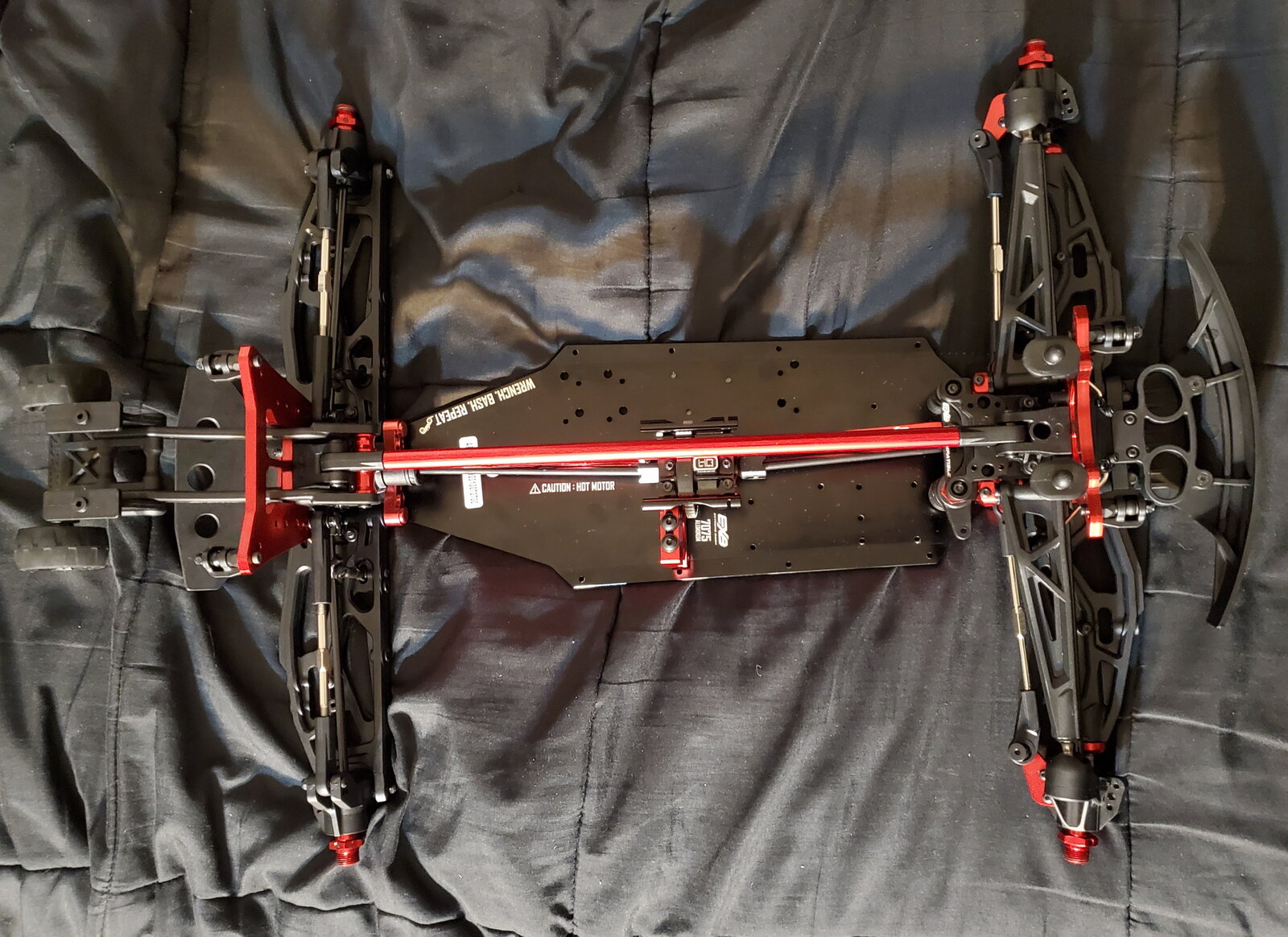

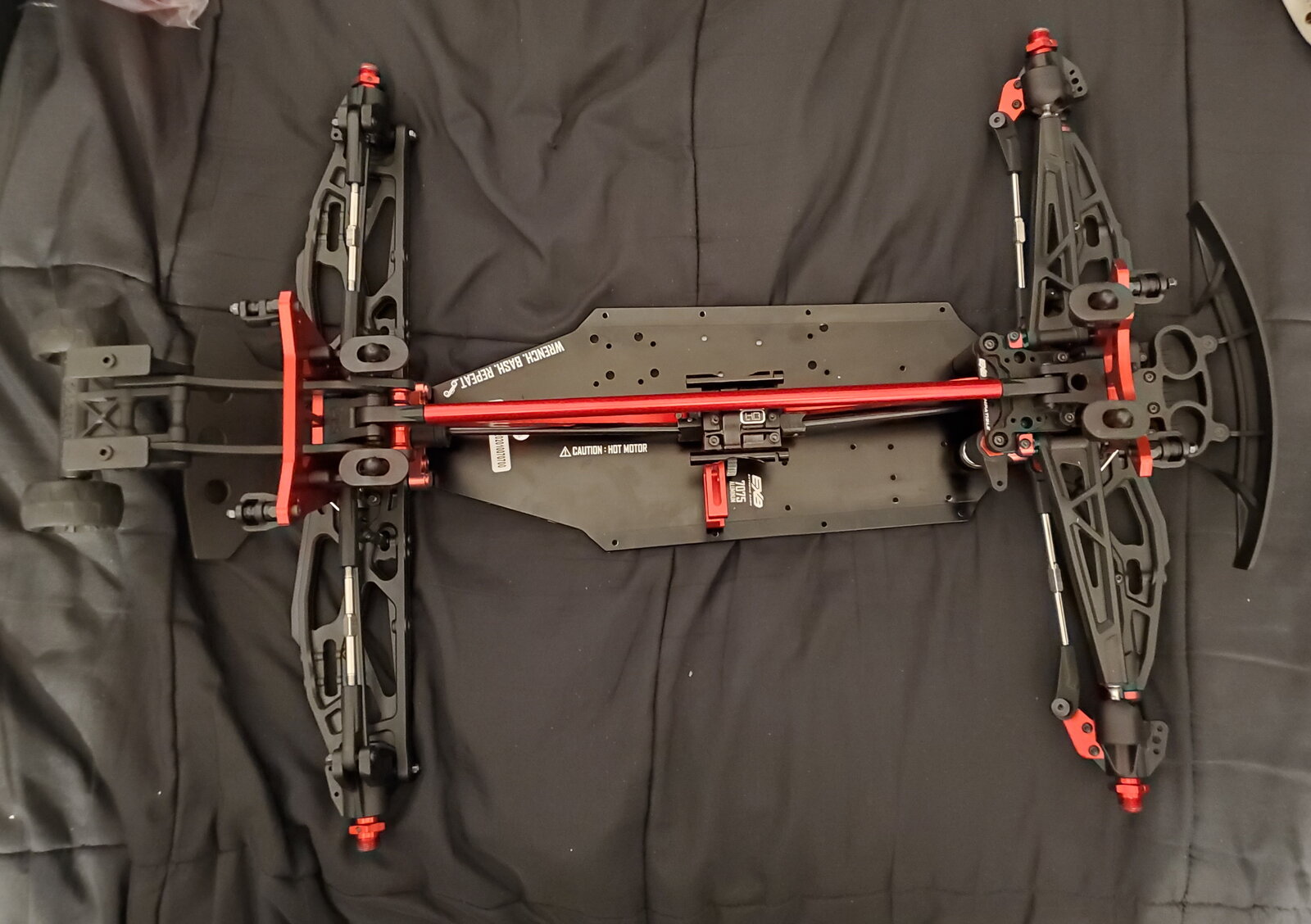

The only other issue with the stock build I ran into was a nut missing from the rear hub where the tie rod installs. Then of course dealing with screws that had too much thread lock. Using a soldering iron I was able to get them all off. The only one I had an issue with was one of the steering posts. But with a lot of heat and some pliers I finally broke the thread lock. Once I had the chassis completely bare I started with the Monster logo chassis protector. That installed very cleanly and easily and came out great. So my beautiful EXB chassis engraving is safe (for now). I also got the GPM red aluminum suspension mounts installed so the front and rear A-Arms and diff assemblies are ready to install. I didnt replace all of the suspension mount parts on this because the EXB already comes with some of the aluminum parts pre-installed.

Day 3:

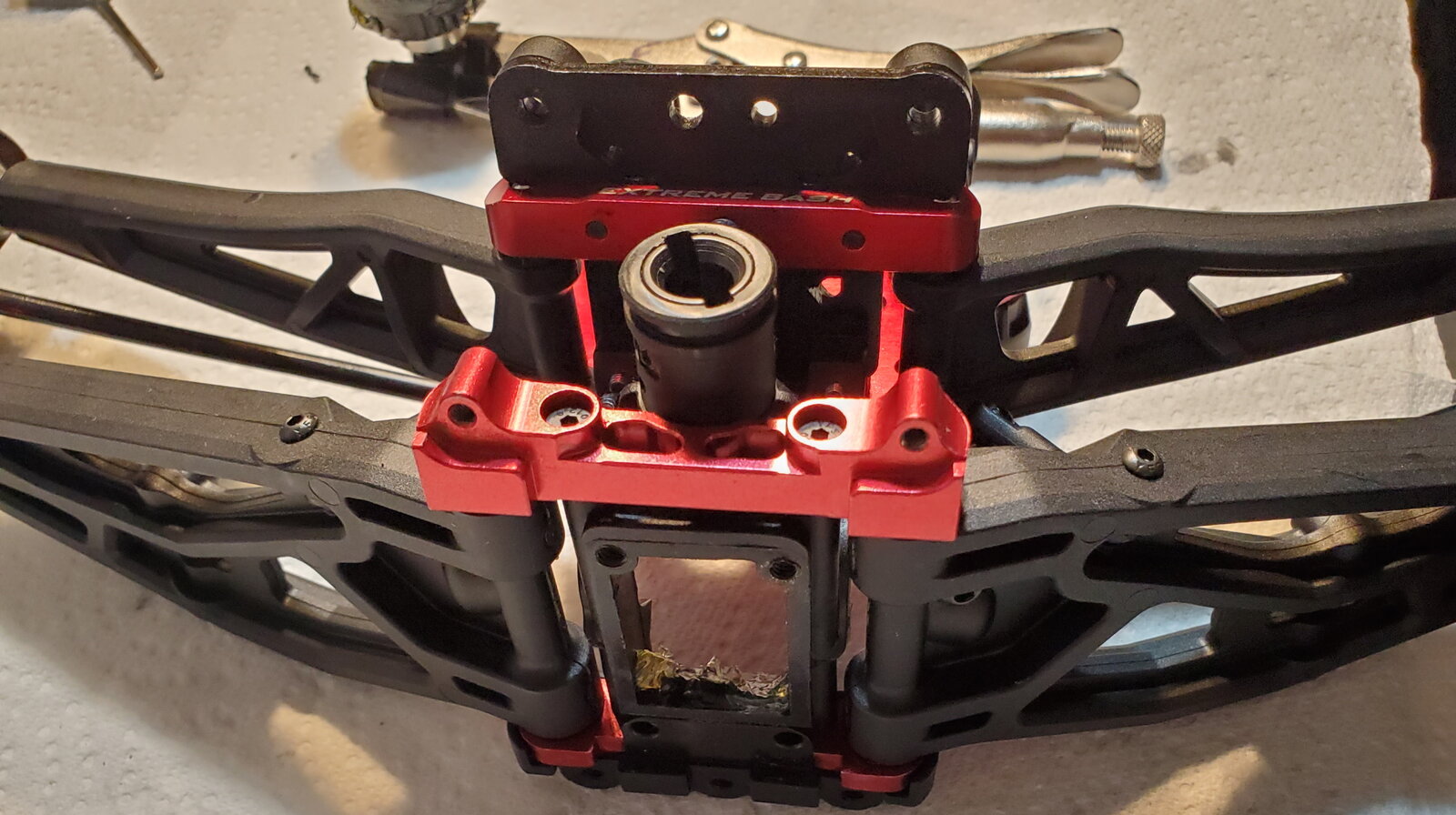

For Day 3 I started with checking the shocks and installing the Tekno balls and ends. The shocks were already perfect as far as the fluids were so I just installed the Tekno parts and they shocks are almost ready to install. Just need to install the Dusty Motor shock covers. Next was starting to put it all back together. I got the front and rear A-arms and diffs installed. The motor mounts, center diff mounts, then installed the new D5 15T pinion onto the Spektrum motor. So the motor with the dual fan set up is ready to install. I then installed the front EXB bumper and the rear T-Bone bumper with the RPM chassis skid. Next was installing the RPM wing mounts with the 6s wheelie bar. I finished off the chassis parts for the day with installing the center diff. So all 3 diffs are done and installed.

Day 4:

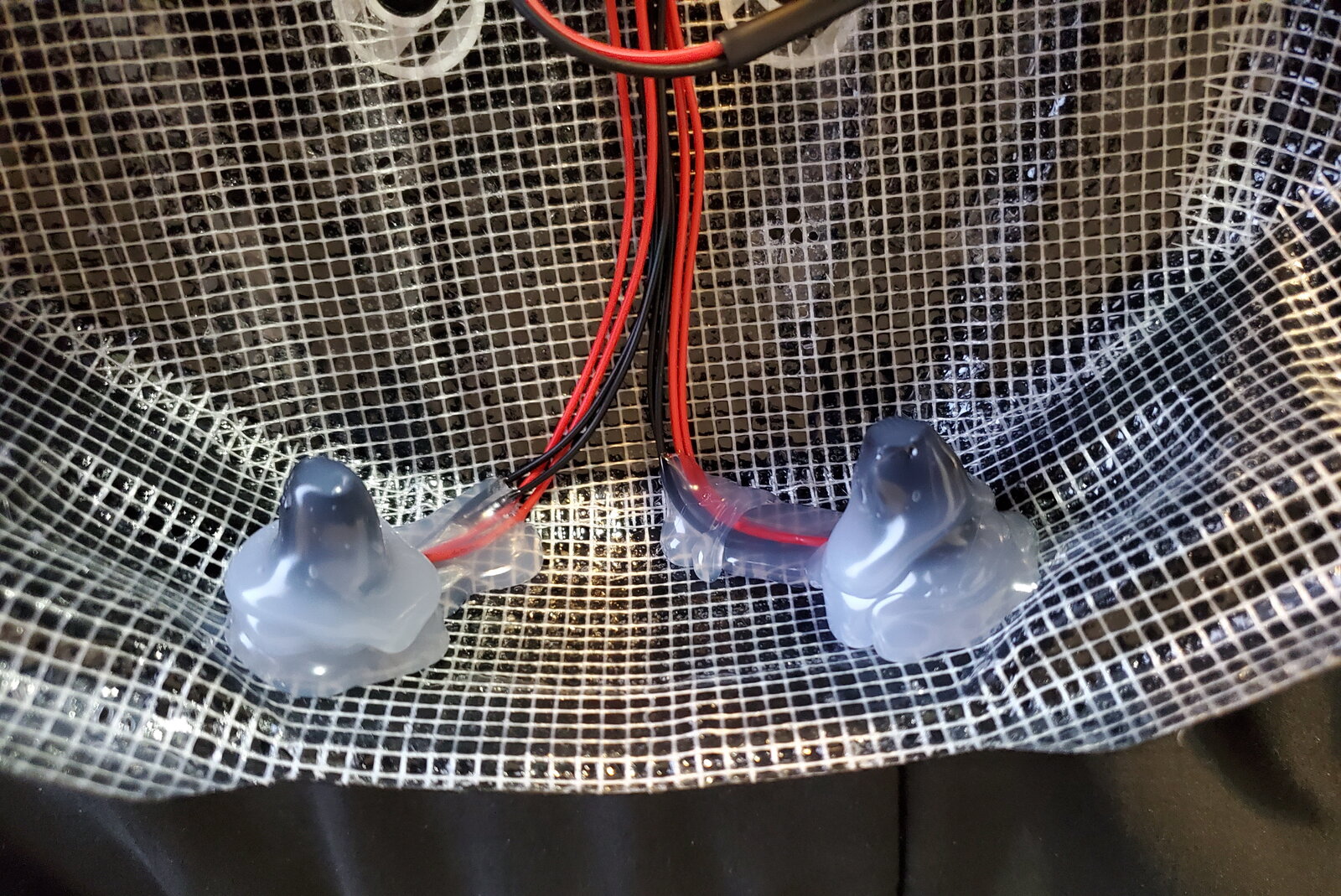

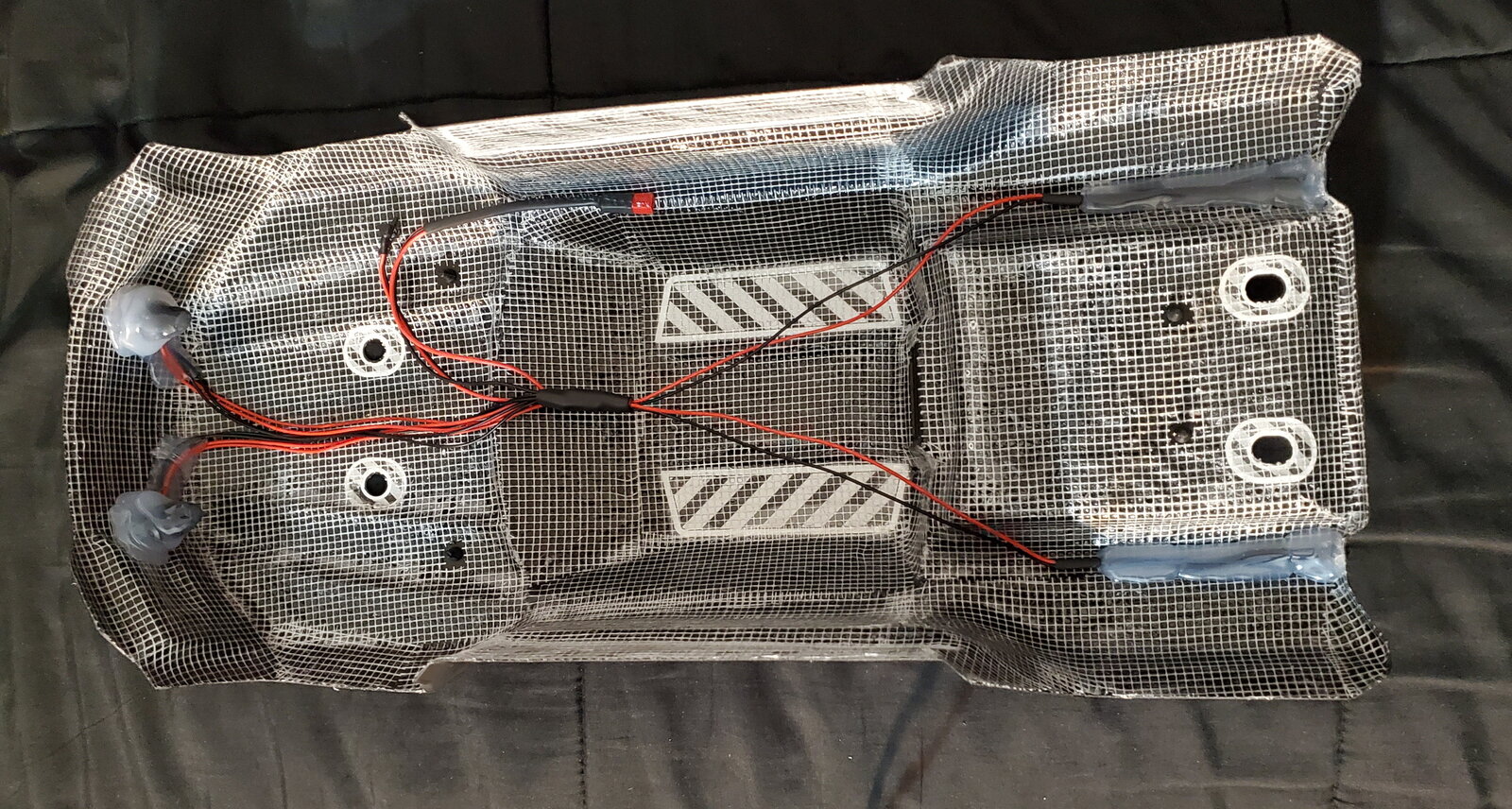

For day 4 I wanted to get the LED install started. I had plans of doing the same LED install I did on the Notorious. So I started by making the power lead I will be running from the receiver to the body. I have JST connectors on the lead and the body which I use to power the LEDs. I just connect the lead when installing the body. The front LED's are also a Halo type with a switch built in that can swap modes between Halo only, or Halo and the center brighter light. So I wired all of this up and installed the fronts directly with hot glue, then the rear red lights with grommets to hold them in and provide some shock absorption. The LED install came out great and is basically done. I just need to hot glue the rest of the wires into place as well as the Halo switch to the inside of the roof.

- Flysky Radio and receiver

- DS3225 35kg Servo

- Hot Racing Diff cases (AON11E02) haven't used, sticking with EXB cases for now

- Hot Racing Aluminum fixed steering link (AON48SH25)

- Hot Racing Aluminum Center Differential Cover (ANN38C01)

- Hot Racing Aluminum Center Differential EZM Mount (ANN38A02)

- Batteries: Hoovo 6S 60C with IC5 connectors X 3

- Chassis Protector (Black and green Monster logo)

- Dual Hobbystar motor fans with red aluminum heat sink

- Diff fluids (Currently stock, but will probably use 60k F, 200 or 500k C, and 30k R)

- T-Bone Typhon front bumper used in rear (TBR 10006) with RPM skid plate (RPM81442)

- Arrma 6s Wheelie bar set (AR320366)

- Dusty Motors shock covers

- GPM Red Aluminum suspension mounts (Didnt need to use all of these since the EXB comes with several preinstalled aluminum mounts)

- Arrma 15T D5 Mod 1 Pinion (ARA310962) Also have D5 14T, D5 15T, and stock D5 12T.

- Tekno Shock Ends and balls (TKR6140C and TKR5049A)

- LED's: Front 10mm Halo and rear 3mm Red Leds

- Body: Reinforced with drywall tape and Shoe Goo

Day 1:

Technically I started the build before I had the new EXB because I had ordered a body and some other parts from Jennys that came before the new EXB did. So on Day 1 I started with reinforcing the body I had ordered with wall tape and Shoe Goo. The next day when I got the truck I did the second body. So these first pics are just both bodies reinforced with tape and glue. Both came out pretty good and are a lot stronger now.

Day 2:

To start Day 2 I did a much more thorough inspection of the truck and started the complete tear down. One of the first things I noticed was the diffs were pretty low. So I topped them off with the stock weight fluids. (10K F, 100K C, and 10K R). Im sure I will change these weights but just wanted to try it out first. I also found out that with the new style diffs you cant fill them as much. When I filled them like the manual shows (which is just like the old style) the fluids overflowed into the screw holes. So I took them back apart and took a bit of the fluids out. Im guessing this is due to the LSD plates taking up more room.

The only other issue with the stock build I ran into was a nut missing from the rear hub where the tie rod installs. Then of course dealing with screws that had too much thread lock. Using a soldering iron I was able to get them all off. The only one I had an issue with was one of the steering posts. But with a lot of heat and some pliers I finally broke the thread lock. Once I had the chassis completely bare I started with the Monster logo chassis protector. That installed very cleanly and easily and came out great. So my beautiful EXB chassis engraving is safe (for now). I also got the GPM red aluminum suspension mounts installed so the front and rear A-Arms and diff assemblies are ready to install. I didnt replace all of the suspension mount parts on this because the EXB already comes with some of the aluminum parts pre-installed.

Day 3:

For Day 3 I started with checking the shocks and installing the Tekno balls and ends. The shocks were already perfect as far as the fluids were so I just installed the Tekno parts and they shocks are almost ready to install. Just need to install the Dusty Motor shock covers. Next was starting to put it all back together. I got the front and rear A-arms and diffs installed. The motor mounts, center diff mounts, then installed the new D5 15T pinion onto the Spektrum motor. So the motor with the dual fan set up is ready to install. I then installed the front EXB bumper and the rear T-Bone bumper with the RPM chassis skid. Next was installing the RPM wing mounts with the 6s wheelie bar. I finished off the chassis parts for the day with installing the center diff. So all 3 diffs are done and installed.

Day 4:

For day 4 I wanted to get the LED install started. I had plans of doing the same LED install I did on the Notorious. So I started by making the power lead I will be running from the receiver to the body. I have JST connectors on the lead and the body which I use to power the LEDs. I just connect the lead when installing the body. The front LED's are also a Halo type with a switch built in that can swap modes between Halo only, or Halo and the center brighter light. So I wired all of this up and installed the fronts directly with hot glue, then the rear red lights with grommets to hold them in and provide some shock absorption. The LED install came out great and is basically done. I just need to hot glue the rest of the wires into place as well as the Halo switch to the inside of the roof.

Last edited: