CustomArrmaBuilds

Member

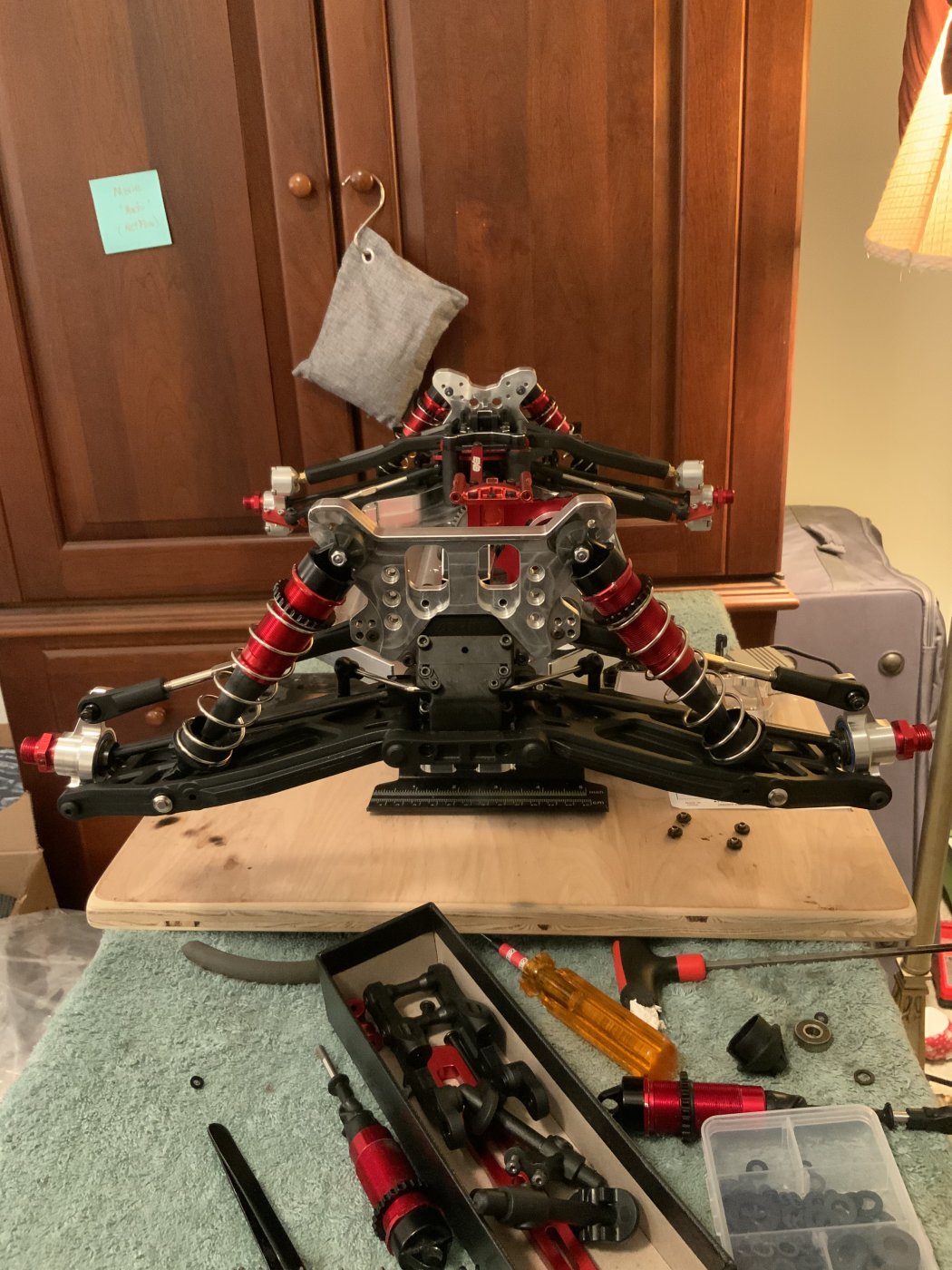

My latest build. (in progress. Roughly 70% complete. Waiting on a few parts still)

Arrma Talion XL (mojave chassis) *** too many aftermarkets for me to list right now. I will repost with list in detail in a day or two when completed. Thanks

Arrma Talion XL (mojave chassis) *** too many aftermarkets for me to list right now. I will repost with list in detail in a day or two when completed. Thanks