@jbeech I had an issue with my DS635BLHV where it for the most part won't move unless you give the servo horn a little bump to get it started in the right direction. I've shelved it for now running my cheapo backup but I'd like to get it put back in soon. I was running the dedicated 2s pack you sell, but it start happening several moments after a bit of a tumble. Is this https://www.promodeler.com/PDRS-HS635 what I need to do when I decide it's time to fix it? I'm assuming it isn't covered under warranty lol

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kraton Best servo money can buy?

- Thread starter Jeremy15086

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

jbeech

Member

- Messages

- 47

- Reaction score

- 176

Likely a bent shaft or damaged gear but it's better not to engage in diagnosis from 1000 miles away. Anyway, yes, you're probbaly correct, not a warranty issue (unless our tech opens it and judges otherwise). Anyway, we made it so we can repair it and my advice is box it up and return it to us for a look-see regarding what's going on. And don't continue running it as they don't heal themselves but can definitely get worse. Heads up, eh? Anyway, because I only know your handle (instead of your name), we can't issue an RMA for you right now. So send us an email: info@promodeler to obtain one. Finally, remember to include a note (basically telling us what you just said) so the tech isn't playing guessing games and knows what to look for (saves times). Our address is;

ProModeler

RMA #

2255 Pine Way

Sanford, FL 32773

Include the RMA # on the note also (plus name and number) since that'll be the serial number identifying the product while it's in the repair facility.

ProModeler

RMA #

2255 Pine Way

Sanford, FL 32773

Include the RMA # on the note also (plus name and number) since that'll be the serial number identifying the product while it's in the repair facility.

- Messages

- 6,083

- Reaction score

- 13,923

- Location

- UK..

- Arrma RC's

- Infraction

- Mojave EXB

- Outcast 8s

- Outcast EXB

- Talion EXB

- Typhon 6s

jbeech

Member

- Messages

- 47

- Reaction score

- 176

Regarding international shipping, yes, we routinely ship to the UK. We also ship to the EU, as well as Eastern Europe, the Middle East, Central Asia, all of Africa, East Asia, Oceania, Antartica, all of South America plus North American neighbors Mexico and Canada (and with Elon Musk's help, some day into orbit and beyond). Don't laugh, you gotta dream and ProModeler began as just that . . . a dream!

Anyway, all it takes are 3 easy steps;

- ProModeler servos being used for simultaneously precision quad steering of laser beams!

Anyway, all it takes are 3 easy steps;

- Register an account (name, email address, and password)

- Add whatever it is you want to your cart

- Check out

- ProModeler servos being used for simultaneously precision quad steering of laser beams!

Last edited:

Arrma Addict

Very Active Member

- Messages

- 385

- Reaction score

- 1,020

- Location

- Minnesooota

- Arrma RC's

- BigRock

- Fazon

- Kraton 8S

- Notorious

- Outcast 8s

- Talion

- Typhon 6s

jkflow

TB RC Bashers

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

Always mind-boggling that a little tumble causes damage....... it start happening several moments after a bit of a tumble.

Definition of a 'bit of a tumble':

jbeech

Member

- Messages

- 47

- Reaction score

- 176

Regarding those Reefs servos, they certainly look nice and it's hard for me to imagine you going wrong with them. That said, I believe we offer some interesting alternatives. While I don't know you, and you haven't mentioned the rig or your personal use for it (there's precision crawling at one extreme and balls to the ball bashing at the other, each presenting a different use-case), I believe we offer suitable servos for you needs.

If a servo using a ø6-25T spline is adequate, our Series I standard size servo range include three alternatives for your consideration. These are our DS505BLHV, DS630BLHV, and DS930BLHV (these are links to all 3).

If you're unfamiliar with our part numbering, breaking the code is easy. Using the DS930BLHV as an example . . .

Finally, with regard to a dig/shift type servo, and presuming some element of water resistance is important, we have three suitable offerings, all three with the convenience of using the exact same ø6-25T spline you're used to with most standard-size servos. These are the DS75CLHV, DS105CLHV, and the absolute jewel of our sub-micro lineup, the DS125CLHV in these photos.

I'll close with this; all nine of the above servos - every single one - rely on 13 o-rings for environmental sealing. They meet three MIL-STDS, have potting compound protecting the circuit boards, use uncompromising all-steel gear trains, and use MIL-SPEC components.

They are built to the finest quality standards . . . yours.

If a servo using a ø6-25T spline is adequate, our Series I standard size servo range include three alternatives for your consideration. These are our DS505BLHV, DS630BLHV, and DS930BLHV (these are links to all 3).

If you're unfamiliar with our part numbering, breaking the code is easy. Using the DS930BLHV as an example . . .

- DS = Digital Servo

- 930 = Torque (oz-in) - or 67Kg-cm if you speak the language of East Asian imports

- BL = Brushless (CL = Coreless, and DL = 3-Pole)

- HV = High Voltage (wide range operation from 4.8 to 8.4VDC)

Finally, with regard to a dig/shift type servo, and presuming some element of water resistance is important, we have three suitable offerings, all three with the convenience of using the exact same ø6-25T spline you're used to with most standard-size servos. These are the DS75CLHV, DS105CLHV, and the absolute jewel of our sub-micro lineup, the DS125CLHV in these photos.

I'll close with this; all nine of the above servos - every single one - rely on 13 o-rings for environmental sealing. They meet three MIL-STDS, have potting compound protecting the circuit boards, use uncompromising all-steel gear trains, and use MIL-SPEC components.

They are built to the finest quality standards . . . yours.

Last edited:

Arrma Addict

Very Active Member

- Messages

- 385

- Reaction score

- 1,020

- Location

- Minnesooota

- Arrma RC's

- BigRock

- Fazon

- Kraton 8S

- Notorious

- Outcast 8s

- Talion

- Typhon 6s

Regarding those Reefs servos, they certainly look nice and it's hard for me to imagine you going wrong with them. That said, I believe we offer some interesting alternatives. While I don't know you, and you haven't mentioned the rig or your personal use for it (there's precision crawling at one extreme and balls to the ball bashing at the other, each presenting a different use-case), I believe we offer suitable servos for you needs.

If a servo using a ø6-25T spline is adequate, our Series I standard size servo range include three alternatives for your consideration. These are our DS505BLHV, DS630BLHV, and DS930BLHV (these are links to all 3).

If you're unfamiliar with our part numbering, breaking the code is easy. Using the DS930BLHV as an example . . .

However, for more robust requirements, we offer our Series II standard size servos, which instead of the 6mm diameter spline share the significantly more beefy ø8-15T output shaft as used with our 1/5th scale servos. Our Series II servos include three more standard size servos in a range extending from DS635BLHV, DS845BLHV, to DS1155BLHV.

- DS = Digital Servo

- 930 = Torque (oz-in) - or 67Kg-cm if you speak the language of East Asian imports

- BL = Brushless (CL = Coreless, and DL = 3-Pole)

- HV = High Voltage (wide range operation from 4.8 to 8.4VDC)

Finally, with regard to a dig/shift type servo, and presuming some element of water resistance is important, we have three suitable offerings, all three with the convenience of using the exact same ø6-25T spline you're used to with most standard-size servos. These are the DS75CLHV, DS105CLHV, and the absolute jewel of our sub-micro lineup, the DS125CLHV in these photos.

View attachment 228045

View attachment 228046

I'll close with this; all nine of the above servos - every single one - rely on 13 o-rings for environmental sealing. They meet three MIL-STDS, have potting compound protecting the circuit boards, use uncompromising all-steel gear trains, and use MIL-SPEC components.

They are built to the finest quality standards . . . yours.

Thank you for the quick reply. That's a great selection!! I will be putting these on a Capra. This is my first crawler; I have homework to do to get it right. I'm sure my driving will be at the speed of a precision driver without the precision. No plans for balls out, have other trucks for that. Looks like I can save a few bucks too. Thank you again.

- Messages

- 6,083

- Reaction score

- 13,923

- Location

- UK..

- Arrma RC's

- Infraction

- Mojave EXB

- Outcast 8s

- Outcast EXB

- Talion EXB

- Typhon 6s

I’m building a kraton exb myself and I ordered a ds35 servo for it and even installed it but then I got to thinking that everything else on the truck is premium so why would I put a dime store servo in it.I have a nice build going. I got my base vehicle (Kraton 6s EXB) in a trade deal and it came with a steering servo in it. Little did I know at the time it was a highly rated cheapo!

There is nothing wrong with that. But it is still a $25 servo in a close to $2k build. I will use it until it dies but I want to have one ready to go for when that eventually happens. I am sure there are 1000000+ "What's the best servo" posts out there and that is very suggestive because of budget vs requirements, etc.

I have a K6 XL build. I am going to use trencher 3.8's for now. My LHC actually recommended Traxxas servos?!!Also, I have a HR 25 tooth servo arm I'd like to use. I will probably be bashing it pretty hard. What are some of the best servos I can get for it if money isn't a factor?

After doing alot of research I decided to go with the D951TW Standard Digital High Torque Titanium Gear Servo from Hitec. Yes there are more expensive servos out there but this one checks all the boxes off in my opinion. It’s got a metal case, titanium gears, it’s programmable and has plenty of torque. Alot of the cheap servos statistics are overrated but not Hitec. You get what you pay for.

slick2500

Anything will break if you drive it wrong enough.

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 26,719

- Reaction score

- 42,023

- Location

- Rapid City, SD

- Arrma RC's

- Fireteam

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Senton 3s

- Typhon 3s

I’m building a kraton exb myself and I ordered a ds35 servo for it and even installed it but then I got to thinking that everything else on the truck is premium so why would I put a dime store servo in it.

After doing alot of research I decided to go with the D951TW Standard Digital High Torque Titanium Gear Servo from Hitec. Yes there are more expensive servos out there but this one checks all the boxes off in my opinion. It’s got a metal case, titanium gears, it’s programmable and has plenty of torque. Alot of the cheap servos statistics are overrated but not Hitec. You get what you pay for.

I am willing to be that even Hitec fibs on their numbers.

jbeech

Member

- Messages

- 47

- Reaction score

- 176

Oh boy, here it is Saturday evening and all I meant to do was check if there were any important emails. Then I noticed an Arrma Forum post so before I goof off tonight, let me share an observation about servo gears. Here goes . . .

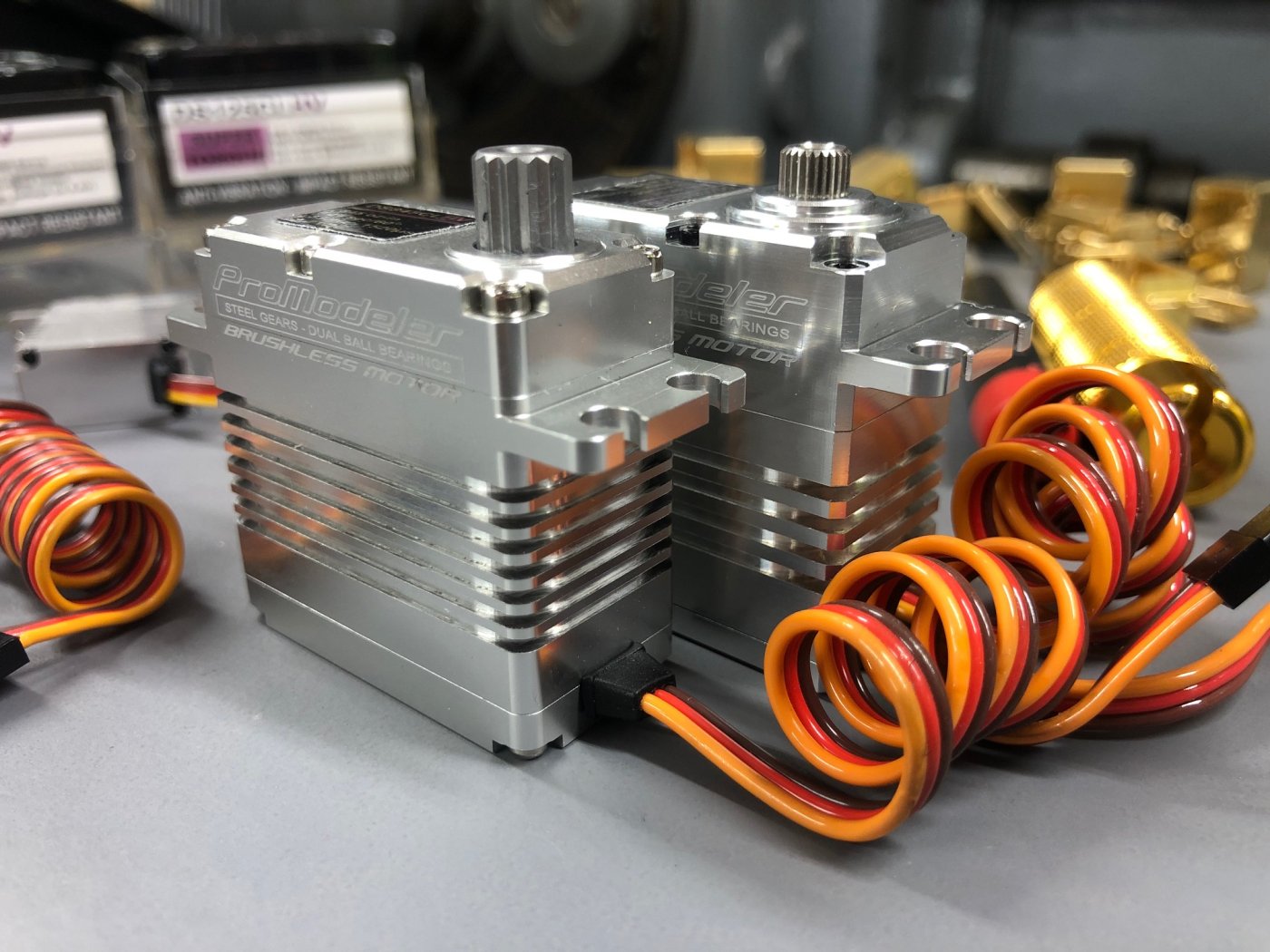

- DS845BLHV versus DS930BLHV . . . Series II vs. Series I standard-size ProModeler servos head to head

Part 1 - is titanium the best for gears?

The only high pressure application I'm aware of where titanium gearing is used are hobby-grade servos. Once you move to professional-grade servos (like what ProModeler specialize in, meaning servos expressly designed for defense and industry), we only use steel gears. Yes, hobbyists buy them as well but 8% of our business doesn't move the needle (meaning hobbyist-sales are not our focus).

Part 2 - psychology

Look, in poker nobody wants the card shark around, right? Some companies employ them, professionally. Psychologists. They know people, their tells. It's my opinion so many guys buying into titanium gears never stood a chance because they loosed the sharks amongst us (psychologists), e.g. the marketing department. These guys know just uttering the words carbon fiber or titanium makes rubes reflexively reach for their wallets because of all we've been taught!

For example, raise your hand if you don't know the lore of the SR-71 Blackbird in which titanium allowed it to go +2200mph. Is it deceptive for marketing to leave non-engineers to believe titanium makes sense as servo gears? Does a material perfect for the skin of something at 900°F because of air friction (Mach 3) make sense in a servo that won't see that kind of temperature even whilst going poof because some fool let 50V loose amongst his 8.4V control electronics? Nope, not in a million years!

But titanium helps sell servos despite being so soft it wears too quickly compared to steel. Honestly, for gears? Titanium sucks! It breaks relatively easily and it's expensive. But marketing doesn't care because their job is to sell servos. So if they befuddle you - all's fair in love and war - right? After all, it was from the Asians themselves there arose the concept of business being war!

So it's my opinion those who initially made the determination servos with titanium gears were a good thing didn't do it because they're dumb, but because they were tricked. Me? I am put in mind of the old saw about fool me once so, when the best marketing companies hire psychologists expressly to manipulate people, (and it's their job, so you can't get mad but it literally Harvard-class trained psych-ops versus regular guys) and I say tricked because it was never a fair contest. Remember, marketing's job is selling snow cones to Eskimos! So my objective with this briefing? To ensure you're not suffering the shame of being fooled twice!

Part 3 - material science

Titanium, very soft compared to steel, and brittle, really only survives in hobby grade-use as gears because they're typically sold to novices. Folk, who whilst often new to the sport are snookered early with buzzword marketing. That, and because rookies are really stressing their equipment like seasoned drivers. What about actual pro-level drivers? Like those featured in magazine advertisements? Don't forget the a, b, c's of marketing; meaning what goes on behind the scenes, which you don't get to see like; a) they're paid to say what they say, b) they're provided servos for free, and c) said servos are frequently exchanged for brand new to maintain their performance.

Anybody giving you new servos for free? Point being, if you're sponsored by Mastercard, here's a tip, buy servos with steel gears for your rigs. Period. And note 1, this is not just my opinion because I have a dog in the hunt representing ProModeler, it's physics - math. Note 2, my pet theory is marketing is who wants titanium, not engineering, Why do I say this? Because just like hairdressers gossip, engineers talk amongst ourselves, the same way. It's a big world but quite tiny, professionally, so I know for a fact they have really good engineers because we talk, we meet at trade shows, and we even knock back a few beers, together. Maybe not friends, but friendly competitors.

But 'Decisions' with a capital-D get made by the C-suite using marketing. Not by engineers, except at ProModeler because we don't have a marketing department. We have no programs, no advertising, no spiffs, no distributors, no teams, no hobby shops, no field rep programs . . . none of the inventions of marketing!

Instead, we iterate our approach until there's nothing left to make better. You know who else does this? Porsche. Eyeball a 911 from 30 years ago and one made yesterday. Both look very much alike; recognizably the same car for their respective eras - but - they are totally different because of an unrelenting focus on making it better. We do this, too.

Don't believe me? You actually don't need to be an engineer, you just need a set of eyes and you can prove it for yourself. Take machinery like construction equipment? Caterpillar comes to mind. Steel gears. Formula 1 cars built with cubic money and making thousands of horsepower? Steel gears. Sticking with the automotive world, NASCAR, their cars 100% use steel gears. Drag racing, the most highly abusive of all equipment? Steel gears. Visit Moab, where guys are crawling in 1:1 scale and guess what? Steel gears - again. Want more proof? My personal Arrma Infraction? Stupid fast. It's equipped with the best aftermarket gears I can buy? Yup, made of steel. So as a wise wag once said . . .

Part 4 - label engineering

The market for RC cars and trucks is hot. Enough so to attract a different class of servos. These are the Asian imports with maybe something like 45Kg lasered on the side. They're sold straight out of the orient by Amazon and eBay and delivered to America by the US Mail and aimed at the unknowing, the inexperienced, plus the bottom feeders building rigs for others. These same manufacturers, if you offer to buy 100 of their servos will put your name on it instead of theirs. This is termed label engineering.

Just also remember, they're large engineered to be cheap. And they're cheaply made. Look inside if you doubt me. You'll see. Major point being, don't mistake brands for actual manufacturers. Not like us, or our top quality competitors like a Futaba, Hitec, Savox, and MKS. The label engineered guys don't make jack. Smart guys? Oh yes, 'not' saying different - but - no engineers on staff, no clue regarding design tools, and certainly no machine tools.

With regard to label engineering brands, I'm kind of put in mind what they say in Texas about guys that are all hat, know what I mean? No, there's nothing wrong with earning money selling something - but - watch out for the quick buck artists, capisce? Those are the ones who approach an Asian manufacturer, doll up a pretty label,and list them on Amazon and eBay for the purpose of turning a fast buck. Thing is, they don't have skin in the game. Not in the same way. Heads up, eh?

Part 5 - so if steel is better, and the best all have steel, how do you make the best?

This part is actually easy. For us at least. To begin, we first made the gears bigger because all else being equal, bigger is better! Stronger. more durable. For competitive reasons we licensed the design to others (because we couldn't afford to defend in international patent courts). We're just too small to take on multinational corporations, so a few bucks in the hand in the way of royalties beats a big fat nothing (and loads of aggravation). Wasn't a hard decision. So we offer standard servos with bigger gears, our Series II servos. Others do also because we gave in to the inevitable. Not proud of it but hey, you do what you have to to survive because you can't eat pride! Better to live to fight another day. Read up on the Wright brothers and their incredible but failed defense of their invention of wing warping for roll control. But there's more but first, eyeball the relative size of the gear trains of our Series II DS845 versus the very well regarded Savox SB2290SG to get an idea of what we mean when we say larger gears. Look at the size of our output gears!

- The high quality Savox SB2290SG has steel gears, and they're about the same size as within the DS930 Series I - but - Series II, like DS845, are larger.

Anyway, another innovation beyond larger gears, includes moving to larger, and far more robust output shaft splines. We're now using the same ø8-15T splines as for our large scale servos. Note the difference in the splines in the above photo as the Savox sports ø6-25T splines versus the massive ø8-15T of the DS845 gear set.

Why larger splines? Simple, it's because we produce standard size servo that are so fast and powerful they can, being made of steel, simply rip the splines made of aluminum within the 25T output shaft-pocket of a servo horn. Wipe them smooth. Clean off - like they were drilled with a 1/4" drill bit.

Note, below is the spline used in all our Series II servos, DS635BLHBV, DS845BLHV, and DS1155BLHV. The DS845 in the photo above is representative of the group. And how is this perspective photo grab you of the DS845BLHV on the left and the DS930BLHV, no slouch in its own right, on the right. The ø6-25T splines on the right are what's on all the label engineered servos and all our competitors except MKS HBL399 which also uses an 8mm spline.

So for these beefier servos (our Series II) we dug into the parts bin and adapted our much larger 1/5th spline to standard size servos. Basically to make their juncture with the servo horn bulletproof. These are massive and exactly like what we use on servos producing 2180oz-in. Bigger? Yes. How much bigger? Their diameter is 33% larger (nominal 8mm diameter instead of 6mm). And equipped with genuinely gnarly teeth (15T instead of 25T) their much larger profile precludes ripping out the inside of the horn. Yes, they're still standard size servos, but with larger gears and with larger spline. Basically, best is down to making the biggest baddest gear trains in the industry. Unmatched by anybody . . . at any price.

What I'm saying is I feel we're unmatched with the DS930 but with our Series II, we clean their clocks. These are bad boys not to be confused with any competitor, none - but least of all - but something that's the product of label engineering. Yet there's more. Now let's take a peek inside.

Part 6 - all standard servo designs are not equal

What do we mean by this? Take a gander at the gear train of a DS930 below. All steel. A beautiful product . . . by any standard! Some might say a work of art. The softly gleaming gear train is strong and part of a purposeful servo better than any made except within our own lineup.

- Finely machined all steel gears of the DS930BLHV servo gleam softly and conceal nothing of the power of this servo.

Maybe after you finish gawking at the gear train, focus inside. Do you see the bronze inserts in the case? They make the pockets into which the steel gear shafts for the transmission section fit. basically, they beef up the case. Bronze isn't as hard as steel but it's a LOT harder than aluminum and it has lubricating properties we desire.

These bits of bronze are known as hard points. Their purpose is keeping the bores for the gear shafts (round) from going egg-shape (not-round) due to the abuse dished out by bashers and their incessant and abusive pounding. They're part of how we keep our gear train together and meeting spec for the gear mesh. Once the bores get beaten so they're not round, gear mesh goes to heck, backlash ensues and before long they fail. Think el cheapo servos have this? Are you kidding me? Heck, even amongst servos selling for more than ours, many don't do it either. However, from amongst the better servos? Like by Futaba, and MKS as examples? Oh yes, amongst our first tier competitors yes, absolutely.

- Look inside is my best advice regarding what separates the men from the boys because details hidden away aren't obvious - so look for yourself!

So if you're going to drop a bundle on the best servo for your rig, then riddle me this, what features do you expect will better protect your investment? will it be the servo with steel shafts sitting directly within aluminum bores, or the more finely made high quality servos made with bronze reinforcements? It's your money. You earned it the hard way, so my advice is don't get beat out of it by tricksters and impersonators.

Bottom line?

Maybe you're not an engineer, but even if you're new and inexperienced in the sport, then after reading this now you better know what to look for. As for the incognito keyboard experts on the internet hiding behind cute handles, and dispensing advice with who knows what for an agenda, I dunno, I have no opinion. Our advice? Watch out for your own best interests and use your eyes because nobody else is gonna do it for you!

- DS845BLHV versus DS930BLHV . . . Series II vs. Series I standard-size ProModeler servos head to head

Part 1 - is titanium the best for gears?

The only high pressure application I'm aware of where titanium gearing is used are hobby-grade servos. Once you move to professional-grade servos (like what ProModeler specialize in, meaning servos expressly designed for defense and industry), we only use steel gears. Yes, hobbyists buy them as well but 8% of our business doesn't move the needle (meaning hobbyist-sales are not our focus).

- My point? If you look at the wider world, specifically amongst the most demanding applications, the gear trains? Steel. Every. Single. Time.

- dismissive

- insulting, or

- condescending

Part 2 - psychology

Look, in poker nobody wants the card shark around, right? Some companies employ them, professionally. Psychologists. They know people, their tells. It's my opinion so many guys buying into titanium gears never stood a chance because they loosed the sharks amongst us (psychologists), e.g. the marketing department. These guys know just uttering the words carbon fiber or titanium makes rubes reflexively reach for their wallets because of all we've been taught!

For example, raise your hand if you don't know the lore of the SR-71 Blackbird in which titanium allowed it to go +2200mph. Is it deceptive for marketing to leave non-engineers to believe titanium makes sense as servo gears? Does a material perfect for the skin of something at 900°F because of air friction (Mach 3) make sense in a servo that won't see that kind of temperature even whilst going poof because some fool let 50V loose amongst his 8.4V control electronics? Nope, not in a million years!

But titanium helps sell servos despite being so soft it wears too quickly compared to steel. Honestly, for gears? Titanium sucks! It breaks relatively easily and it's expensive. But marketing doesn't care because their job is to sell servos. So if they befuddle you - all's fair in love and war - right? After all, it was from the Asians themselves there arose the concept of business being war!

So it's my opinion those who initially made the determination servos with titanium gears were a good thing didn't do it because they're dumb, but because they were tricked. Me? I am put in mind of the old saw about fool me once so, when the best marketing companies hire psychologists expressly to manipulate people, (and it's their job, so you can't get mad but it literally Harvard-class trained psych-ops versus regular guys) and I say tricked because it was never a fair contest. Remember, marketing's job is selling snow cones to Eskimos! So my objective with this briefing? To ensure you're not suffering the shame of being fooled twice!

Part 3 - material science

Titanium, very soft compared to steel, and brittle, really only survives in hobby grade-use as gears because they're typically sold to novices. Folk, who whilst often new to the sport are snookered early with buzzword marketing. That, and because rookies are really stressing their equipment like seasoned drivers. What about actual pro-level drivers? Like those featured in magazine advertisements? Don't forget the a, b, c's of marketing; meaning what goes on behind the scenes, which you don't get to see like; a) they're paid to say what they say, b) they're provided servos for free, and c) said servos are frequently exchanged for brand new to maintain their performance.

Anybody giving you new servos for free? Point being, if you're sponsored by Mastercard, here's a tip, buy servos with steel gears for your rigs. Period. And note 1, this is not just my opinion because I have a dog in the hunt representing ProModeler, it's physics - math. Note 2, my pet theory is marketing is who wants titanium, not engineering, Why do I say this? Because just like hairdressers gossip, engineers talk amongst ourselves, the same way. It's a big world but quite tiny, professionally, so I know for a fact they have really good engineers because we talk, we meet at trade shows, and we even knock back a few beers, together. Maybe not friends, but friendly competitors.

But 'Decisions' with a capital-D get made by the C-suite using marketing. Not by engineers, except at ProModeler because we don't have a marketing department. We have no programs, no advertising, no spiffs, no distributors, no teams, no hobby shops, no field rep programs . . . none of the inventions of marketing!

Instead, we iterate our approach until there's nothing left to make better. You know who else does this? Porsche. Eyeball a 911 from 30 years ago and one made yesterday. Both look very much alike; recognizably the same car for their respective eras - but - they are totally different because of an unrelenting focus on making it better. We do this, too.

Don't believe me? You actually don't need to be an engineer, you just need a set of eyes and you can prove it for yourself. Take machinery like construction equipment? Caterpillar comes to mind. Steel gears. Formula 1 cars built with cubic money and making thousands of horsepower? Steel gears. Sticking with the automotive world, NASCAR, their cars 100% use steel gears. Drag racing, the most highly abusive of all equipment? Steel gears. Visit Moab, where guys are crawling in 1:1 scale and guess what? Steel gears - again. Want more proof? My personal Arrma Infraction? Stupid fast. It's equipped with the best aftermarket gears I can buy? Yup, made of steel. So as a wise wag once said . . .

Part 4 - label engineering

The market for RC cars and trucks is hot. Enough so to attract a different class of servos. These are the Asian imports with maybe something like 45Kg lasered on the side. They're sold straight out of the orient by Amazon and eBay and delivered to America by the US Mail and aimed at the unknowing, the inexperienced, plus the bottom feeders building rigs for others. These same manufacturers, if you offer to buy 100 of their servos will put your name on it instead of theirs. This is termed label engineering.

Just also remember, they're large engineered to be cheap. And they're cheaply made. Look inside if you doubt me. You'll see. Major point being, don't mistake brands for actual manufacturers. Not like us, or our top quality competitors like a Futaba, Hitec, Savox, and MKS. The label engineered guys don't make jack. Smart guys? Oh yes, 'not' saying different - but - no engineers on staff, no clue regarding design tools, and certainly no machine tools.

With regard to label engineering brands, I'm kind of put in mind what they say in Texas about guys that are all hat, know what I mean? No, there's nothing wrong with earning money selling something - but - watch out for the quick buck artists, capisce? Those are the ones who approach an Asian manufacturer, doll up a pretty label,and list them on Amazon and eBay for the purpose of turning a fast buck. Thing is, they don't have skin in the game. Not in the same way. Heads up, eh?

Part 5 - so if steel is better, and the best all have steel, how do you make the best?

This part is actually easy. For us at least. To begin, we first made the gears bigger because all else being equal, bigger is better! Stronger. more durable. For competitive reasons we licensed the design to others (because we couldn't afford to defend in international patent courts). We're just too small to take on multinational corporations, so a few bucks in the hand in the way of royalties beats a big fat nothing (and loads of aggravation). Wasn't a hard decision. So we offer standard servos with bigger gears, our Series II servos. Others do also because we gave in to the inevitable. Not proud of it but hey, you do what you have to to survive because you can't eat pride! Better to live to fight another day. Read up on the Wright brothers and their incredible but failed defense of their invention of wing warping for roll control. But there's more but first, eyeball the relative size of the gear trains of our Series II DS845 versus the very well regarded Savox SB2290SG to get an idea of what we mean when we say larger gears. Look at the size of our output gears!

- The high quality Savox SB2290SG has steel gears, and they're about the same size as within the DS930 Series I - but - Series II, like DS845, are larger.

Anyway, another innovation beyond larger gears, includes moving to larger, and far more robust output shaft splines. We're now using the same ø8-15T splines as for our large scale servos. Note the difference in the splines in the above photo as the Savox sports ø6-25T splines versus the massive ø8-15T of the DS845 gear set.

Why larger splines? Simple, it's because we produce standard size servo that are so fast and powerful they can, being made of steel, simply rip the splines made of aluminum within the 25T output shaft-pocket of a servo horn. Wipe them smooth. Clean off - like they were drilled with a 1/4" drill bit.

Note, below is the spline used in all our Series II servos, DS635BLHBV, DS845BLHV, and DS1155BLHV. The DS845 in the photo above is representative of the group. And how is this perspective photo grab you of the DS845BLHV on the left and the DS930BLHV, no slouch in its own right, on the right. The ø6-25T splines on the right are what's on all the label engineered servos and all our competitors except MKS HBL399 which also uses an 8mm spline.

So for these beefier servos (our Series II) we dug into the parts bin and adapted our much larger 1/5th spline to standard size servos. Basically to make their juncture with the servo horn bulletproof. These are massive and exactly like what we use on servos producing 2180oz-in. Bigger? Yes. How much bigger? Their diameter is 33% larger (nominal 8mm diameter instead of 6mm). And equipped with genuinely gnarly teeth (15T instead of 25T) their much larger profile precludes ripping out the inside of the horn. Yes, they're still standard size servos, but with larger gears and with larger spline. Basically, best is down to making the biggest baddest gear trains in the industry. Unmatched by anybody . . . at any price.

What I'm saying is I feel we're unmatched with the DS930 but with our Series II, we clean their clocks. These are bad boys not to be confused with any competitor, none - but least of all - but something that's the product of label engineering. Yet there's more. Now let's take a peek inside.

Part 6 - all standard servo designs are not equal

What do we mean by this? Take a gander at the gear train of a DS930 below. All steel. A beautiful product . . . by any standard! Some might say a work of art. The softly gleaming gear train is strong and part of a purposeful servo better than any made except within our own lineup.

- Finely machined all steel gears of the DS930BLHV servo gleam softly and conceal nothing of the power of this servo.

Maybe after you finish gawking at the gear train, focus inside. Do you see the bronze inserts in the case? They make the pockets into which the steel gear shafts for the transmission section fit. basically, they beef up the case. Bronze isn't as hard as steel but it's a LOT harder than aluminum and it has lubricating properties we desire.

These bits of bronze are known as hard points. Their purpose is keeping the bores for the gear shafts (round) from going egg-shape (not-round) due to the abuse dished out by bashers and their incessant and abusive pounding. They're part of how we keep our gear train together and meeting spec for the gear mesh. Once the bores get beaten so they're not round, gear mesh goes to heck, backlash ensues and before long they fail. Think el cheapo servos have this? Are you kidding me? Heck, even amongst servos selling for more than ours, many don't do it either. However, from amongst the better servos? Like by Futaba, and MKS as examples? Oh yes, amongst our first tier competitors yes, absolutely.

- Look inside is my best advice regarding what separates the men from the boys because details hidden away aren't obvious - so look for yourself!

So if you're going to drop a bundle on the best servo for your rig, then riddle me this, what features do you expect will better protect your investment? will it be the servo with steel shafts sitting directly within aluminum bores, or the more finely made high quality servos made with bronze reinforcements? It's your money. You earned it the hard way, so my advice is don't get beat out of it by tricksters and impersonators.

Bottom line?

Maybe you're not an engineer, but even if you're new and inexperienced in the sport, then after reading this now you better know what to look for. As for the incognito keyboard experts on the internet hiding behind cute handles, and dispensing advice with who knows what for an agenda, I dunno, I have no opinion. Our advice? Watch out for your own best interests and use your eyes because nobody else is gonna do it for you!

Last edited:

Is backard bashing an application where these incredibly high quality (and expensive) servos are suitable? Or are they more suited to competitive racing, etc. where you need the best of the best? Like I don't buy a competition race ready Porsche to drive around in New york city because it's overkill and can't use its potential. Am I missing something? I'm new so I don't know any better!

Last edited:

- Messages

- 6,083

- Reaction score

- 13,923

- Location

- UK..

- Arrma RC's

- Infraction

- Mojave EXB

- Outcast 8s

- Outcast EXB

- Talion EXB

- Typhon 6s

That's a valid point you make..!!Is backard bashing an application where these incredibly high quality (and expensive) servos are suitable? Or are they more suited to competitive racing, etc. where you need the best of the best? Like I don't buy a competition race ready Porsche to drive around in New york city because it's overkill and can't use its potential. Am I missing something?

jbeech

Member

- Messages

- 47

- Reaction score

- 176

abh16 asks an incredibly insightful question, which I summarize as, 'Do I really need to pony up for a servo of this class if I'm just bashing?'Is backard bashing an application where these incredibly high quality (and expensive) servos are suitable? Or are they more suited to competitive racing, etc. where you need the best of the best? Like I don't buy a competition race ready Porsche to drive around in New york city because it's overkill and can't use its potential. Am I missing something?

Well, I answer this very question within this askJOHN white paper where we take a $60 BETU 45KG servo we bought off Amazon and put head-to-head with our entry level DS505BLHV at $100;

Do I need servos like these just for bashing?

I guess the next question would be what empirical data do we have that demonstrates those points you addressed (higher grade gear material selection, larger diameter gear shafts, etc.) and its real world effect. Yes, it certainly seems better to have a 33% larger diameter gear shaft but are the smaller shafts breaking that demonstrates a need for the larger shaft? Is there another benefit like does a larger shaft transfer power more efficiently or something? Is utilizing a higher grade material in the steel gears improve useful lifeby how much...20% 100%? Are we talking months vs years?Gears that last twice as long would be a big difference then just a little longer useful life in the conditions we subject them. Data like this available?

Last edited:

Audi X-Maxx

Member

- Messages

- 24

- Reaction score

- 59

ABH16,I guess the next question would be what empirical data do we have that demonstrates those points you addressed (higher grade gear material selection, larger diameter gear shafts, etc.) and its real world effect. Yes, it certainly seems better to have a 33% larger diameter gear shaft but are the smaller shafts breaking that demonstrates a need for the larger shaft? Is there another benefit like does a larger shaft transfer power more efficiently or something? Is utilizing a higher grade material in the steel gears improve useful lifeby how much...20% 100%? Are we talking months vs years?Gears that last twice as long would be a big difference then just a little longer useful life in the conditions we subject them. Data like this available?

The answer to your question is really out of scope for the end-user but the data you are seeking is available through many different channels. Essentially, the minimum shaft diameter required by NEMA is a diameter that will not deflect more than 1 degree by a shaft 20x its length. But look around and you will see that most major companies will use a diameter up to 5x that amount... why? because for certain applications, a broken motor shaft could be catastrophic. If you want an overview of all the formulas and how to calculate: https://www.sciencedirect.com/topics/engineering/shaft-diameter

The overall longevity of any electric motor is a direct result of how it is used and the external environment it is subjected to. Heat, moisture, voltage spikes, ripple current, too much load, too little load... are all things that contribute to the wear & tear of a motor and it's components. as far as the steel used... there are many factors involved: Strength, Hardness, Ductility, Weldability and Durability. These are all different properties used to rate steel and these properties change significantly when tempering is involved. For example, a medium strength steel, like C#45 is not the strongest but once it has been chemically tempered, its Rockwell hardness factor goes way up. 4140, 4340, TiGr5, etc.... all have different attributes that make them useful in different scenarios... for Servos, the options are: Steel, Steel and Steel....

Back to the question I think you are asking: whats the benefit of a larger diameter motor shaft on my application? Well, if you have an arma vehicle and have ever changed the pitch size, then you will know that having a bigger pitch gear makes for better surface area contact, especially when the spur shaft is subject to moving around from a hard landing or general bashing around. When it comes to a servo, the better surface area contact, the less likely you will strip out the servo horn. It's much more difficult to strip a 15T spline than a 25T spline because of simple physics: better surface area contact, which translates into higher power transfer and yes, smoother operation (efficiency). How much more? who cares! as long as it doesn't strip servo horns anymore right?

And sure, a porsche in New York is overkill, yet, they are still everywhere in New York. Why? because there are still people that want to have a performance driven vehicle that they can rely on... Of course, they could always drive a POS car but what part of New York will they be when it breaks down out of nowhere... Same thing here... These servos are built with this in mind: Reliable Performance. Everytime.

I might be led to believe people drive race-ready Porsches in NYC probably because they like to flaunt their wealth and appear hip and cool. Not because they are suitable for the application, namely a racetrack. Driving the best race tires across bad pavement is much less desirable then a lage sidewall and soft compound tires. Same idea I'm trying to explore with these rc servos.

In regards to your comment I don't feel my questions be beyond the scope for the end user. Why send extra money on something that is not going to have real world benefits. Are end users striping their 25T so often that an upgrade to 15T makes sense? To say 15T is much stronger, much more efficient,etc but suggests "who cares" how much better. Well I as an end user cares how much better before I agree it's worth the added cost. I'm still new here so this issue has probably been explored endlessly already

I'm shopping for a servo for my new 1/5 kraton 8s roller so I'm coming at this issue as an end user. Ive also replaced half a dozen smaller servvv on my 3s and 6s RCs. Those amazon servos look very tempting to me as a still new and under-educated RC enthusiast. But reading through Mr. Jbeech and other's posts makes me feel that a premium quality servo may be worth the higher cost. Lots to learn.

In regards to your comment I don't feel my questions be beyond the scope for the end user. Why send extra money on something that is not going to have real world benefits. Are end users striping their 25T so often that an upgrade to 15T makes sense? To say 15T is much stronger, much more efficient,etc but suggests "who cares" how much better. Well I as an end user cares how much better before I agree it's worth the added cost. I'm still new here so this issue has probably been explored endlessly already

I'm shopping for a servo for my new 1/5 kraton 8s roller so I'm coming at this issue as an end user. Ive also replaced half a dozen smaller servvv on my 3s and 6s RCs. Those amazon servos look very tempting to me as a still new and under-educated RC enthusiast. But reading through Mr. Jbeech and other's posts makes me feel that a premium quality servo may be worth the higher cost. Lots to learn.

Last edited:

Audi X-Maxx

Member

- Messages

- 24

- Reaction score

- 59

I’m saying the end user isn’t usually interested in knowing a quantitative analysis of of how broader surface surface contact makes for better power transfer or exactly how much more load the shaft can bear by increasing the diameter by even a single kilometer. But I found a calculator to provide the results and it appears that 1mm increase in shaft diameter results in an additional 28N/mm^3 force the threshold for load transfer from 50 to 78N/mm.I might be led to believe people drive race-ready Porsches in NYC probably because they like to flaunt their wealth and appear hip and cool. Not because they are suitable for the application, namely a racetrack. Driving the best race tires across bad pavement is much less desirable then a lage sidewall and soft compound tires. Same idea I'm trying to explore with these rc servos.

In regards to your comment I don't feel my questions be beyond the scope for the end user. Why send extra money on something that is not going to have real world benefits. Are end users striping their 25T so often that an upgrade to 15T makes sense? To say 15T is much stronger, much more efficient,etc but suggests "who cares" how much better. Well I as an end user cares how much better before I agree it's worth the added cost. I'm still new here so this issue has probably been explored endlessly already

I'm shopping for a servo for my new 1/5 kraton 8s roller so I'm coming at this issue as an end user. Ive also replaced half a dozen smaller servvv on my 3s and 6s RCs. Those amazon servos look very tempting to me as a still new and under-educated RC enthusiast. But reading through Mr. Jbeech and other's posts makes me feel that a premium quality servo may be worth the higher cost. Lots to learn.

If shopping for a K8S EXB servo, I can attest to having used plenty of 65kg, 73kg and 90kg servos only to break the main output shaft. It’s the impact shock that kills the servo, so the structural integrity is what begins to play a critical role in durability over time. At some point, time becomes more valuable than the extra $$ spent on quality. PM servos are the best decision I’ve made and I use them in all my builds. From X-Maxx to K12-EXB to 5iveT conversions.

You won’t regret it. And you’ll be glad you went with the PM servo. Bash On!

Similar threads

- Replies

- 8

- Views

- 422