Picked up in Feb 2021, getting back into RC after ~17yrs. Saw a dude walking in the park driving one last summer and it set the wheels in motion and got me looking into them.

OG V1 Everything Stock except I swapped the deans connectors to IC5

Within the first couple times driving it , the servo died and quick and painless death. After some research I learned thats kinda just a thing that happens and to keep them in stock lol. I went with the JX CLS-HV7346MG . I picked up a Flysky FS-GT5 at the same time for separate L/R steering EPA adjustment, plus I just wanted a better remote

Before I drove it for the first time I went to my local hobby shop which is small and I was talking with the owner about buying this used Kraton and what maintenance I should perform and his response was "None, drive it till you break it". What I wished he would have told me was check the diffs haha. At this point I had the car a week or so and not doing any kind of crazy driving and all the sudden it stopped driving. Turned out to be a broken center diff gear. I was lucky to find a complete center diff from my LHS so in it went with 100K oil.

After that, I was back to bashing. Buddy and I found a sweet local spot. Giant mounds of dirt for local city trail repair.

Dug in a few jumps

After driving around in a local park and popped the body off after ~20 mins of driving and saw my motor had melted the plastic cover for the wires. I did several full throttle pulls in medium grass, nothing too crazy. I have been told by a few people now they're not surprised.

At this point I have had the car down more then up and as I do more research I am learning what a money sink these things can be, especially starting back off as a n00b with a used Kraton 6s. I also started having trouble with the pillar ball screws backing out, and the pillar ball cap on one side feels cross threaded so it was hard to adjust the tension. So at this point I am bummed having some issues, and a little disappointed and I don't know what else to do except to double down and buy and EXB

The V1 Kraton sits quite a bit lower than the newer models and the EXB. Starting with V2 heavier shock springs were from the factory

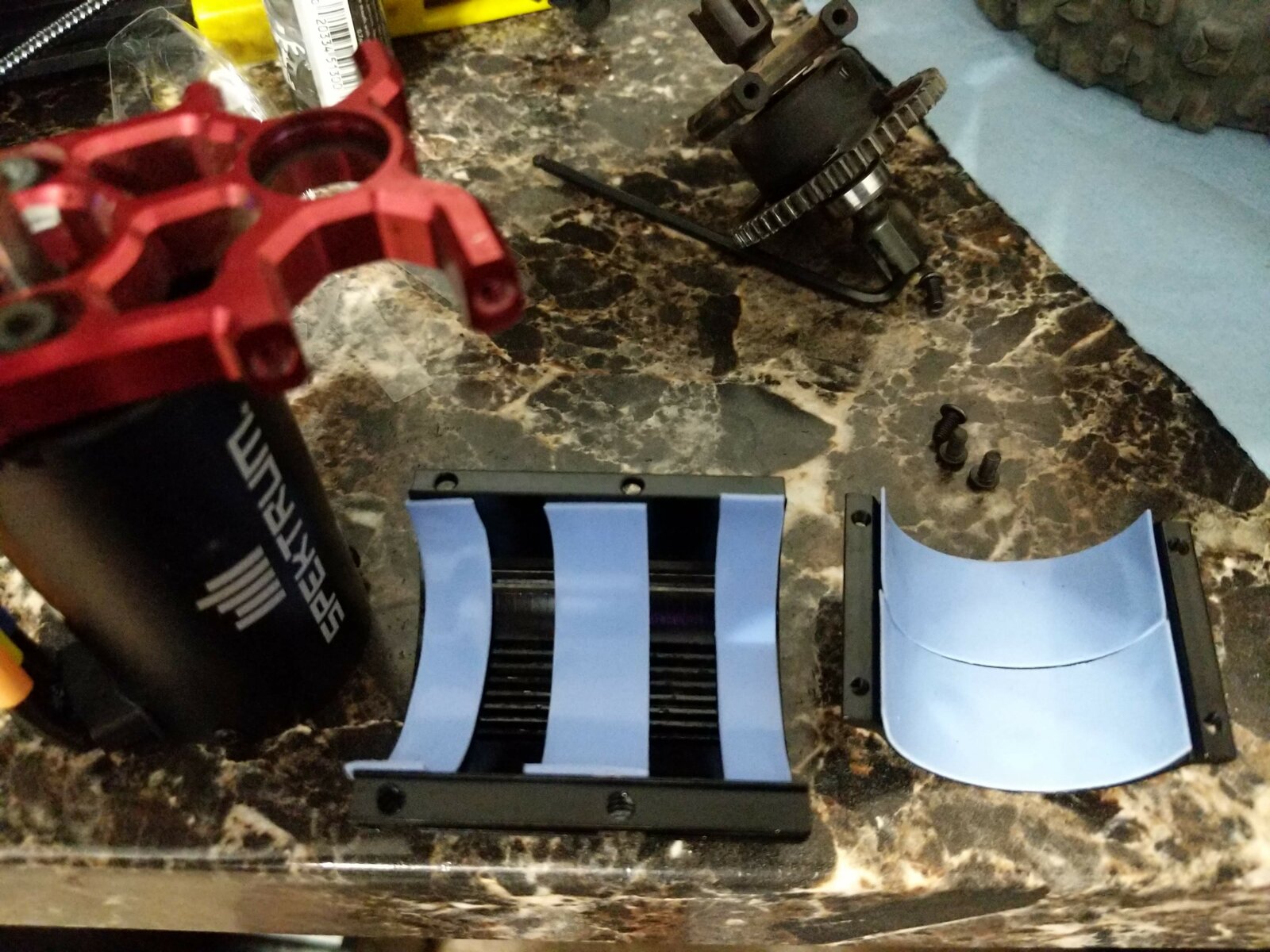

I figure with 2 Kratons I should be able to keep one going while the other is getting repaired lol. For the EXB I went with the Hobbywing Max6/1650kv and ordered the same JX servo and another Flysky receiver. For the V1 Kraton, now dubbed The Beater, I picked up a new take off Spektrum motor from JennyRC. I also picked up RPM front arms upper/lower, Kraton V2 shock springs, and front/rear knuckles. Once I got the new Spektrum motor installed I found the ESC fried also, so I picked up a Spektrum 150A from my LHS. I also installed a yeah racing heatsink/fan on the Spektrum motor for the V1.

OG V1 Everything Stock except I swapped the deans connectors to IC5

Within the first couple times driving it , the servo died and quick and painless death. After some research I learned thats kinda just a thing that happens and to keep them in stock lol. I went with the JX CLS-HV7346MG . I picked up a Flysky FS-GT5 at the same time for separate L/R steering EPA adjustment, plus I just wanted a better remote

Before I drove it for the first time I went to my local hobby shop which is small and I was talking with the owner about buying this used Kraton and what maintenance I should perform and his response was "None, drive it till you break it". What I wished he would have told me was check the diffs haha. At this point I had the car a week or so and not doing any kind of crazy driving and all the sudden it stopped driving. Turned out to be a broken center diff gear. I was lucky to find a complete center diff from my LHS so in it went with 100K oil.

After that, I was back to bashing. Buddy and I found a sweet local spot. Giant mounds of dirt for local city trail repair.

Dug in a few jumps

After driving around in a local park and popped the body off after ~20 mins of driving and saw my motor had melted the plastic cover for the wires. I did several full throttle pulls in medium grass, nothing too crazy. I have been told by a few people now they're not surprised.

At this point I have had the car down more then up and as I do more research I am learning what a money sink these things can be, especially starting back off as a n00b with a used Kraton 6s. I also started having trouble with the pillar ball screws backing out, and the pillar ball cap on one side feels cross threaded so it was hard to adjust the tension. So at this point I am bummed having some issues, and a little disappointed and I don't know what else to do except to double down and buy and EXB

The V1 Kraton sits quite a bit lower than the newer models and the EXB. Starting with V2 heavier shock springs were from the factory

I figure with 2 Kratons I should be able to keep one going while the other is getting repaired lol. For the EXB I went with the Hobbywing Max6/1650kv and ordered the same JX servo and another Flysky receiver. For the V1 Kraton, now dubbed The Beater, I picked up a new take off Spektrum motor from JennyRC. I also picked up RPM front arms upper/lower, Kraton V2 shock springs, and front/rear knuckles. Once I got the new Spektrum motor installed I found the ESC fried also, so I picked up a Spektrum 150A from my LHS. I also installed a yeah racing heatsink/fan on the Spektrum motor for the V1.

Last edited: