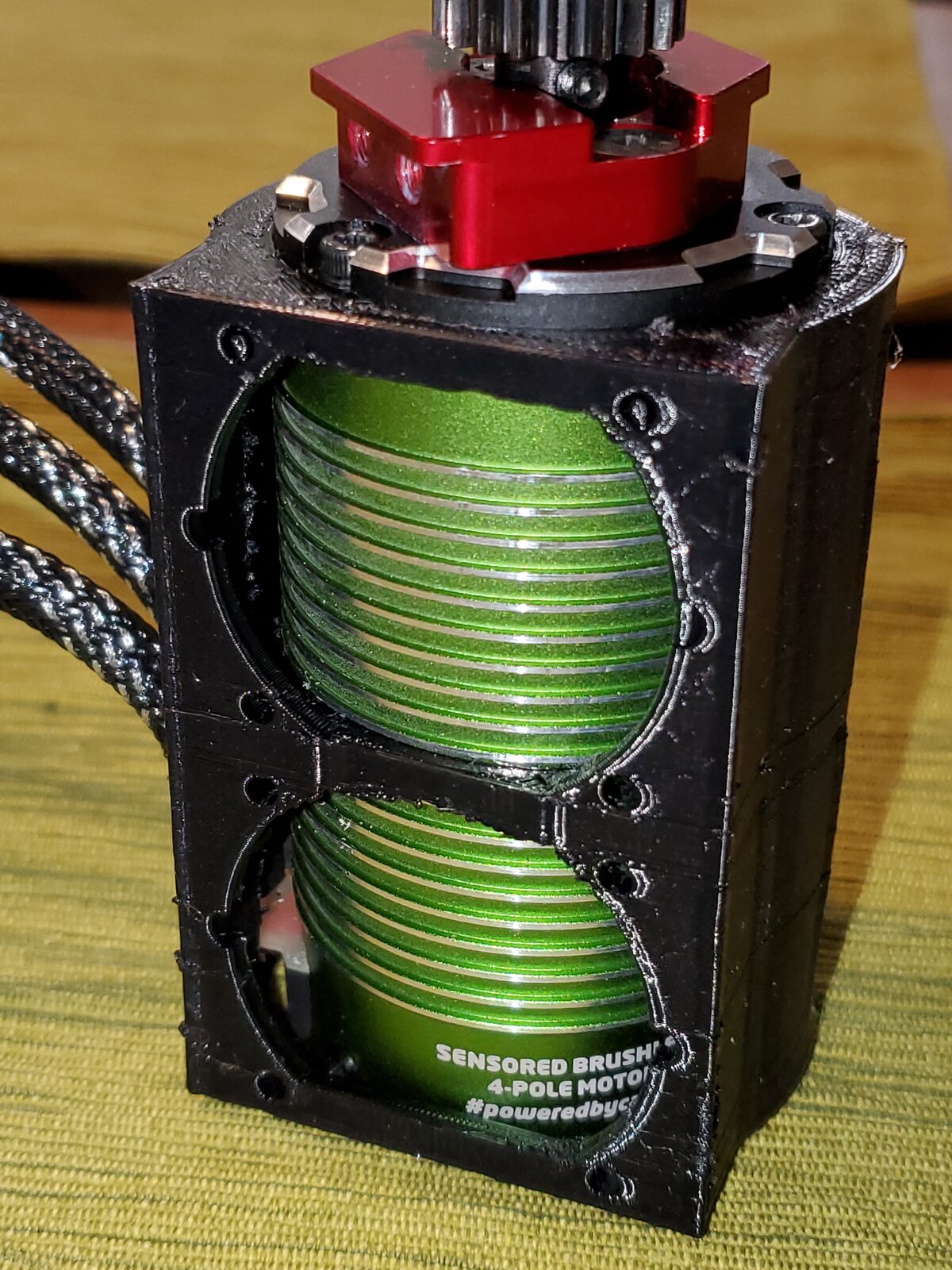

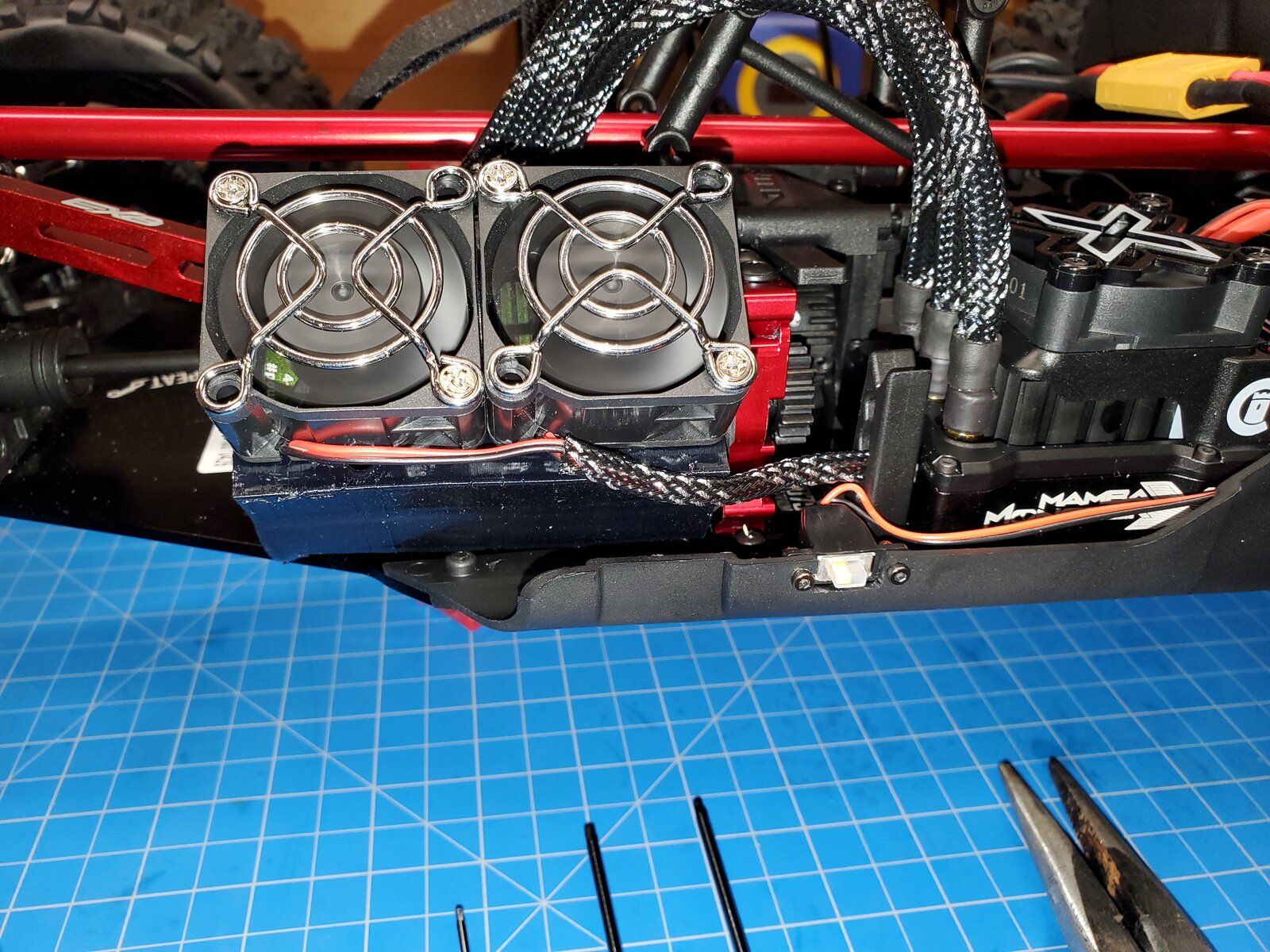

I started modifying an 8s heatsink to fit the Castle 1717, but as i was sliding it on/off I noticed that it was wearing the paint on the heatsink in just a few small places, which indicated to me that it wasn't getting good contact for heat transfer. Since the 1717 can has built-in fins, I decided to use the direct cooling method with a few 40mm fans, but i wanted to get turbulent flow around more of the motor's surface area, so I designed and 3d printed a "shroud" to fit over the motor with a small annular space that would direct the flow of air from the fans around the can. Anyway, it seems like a lot of people struggle with cooling this motor, so I thought I would share this as another option. It does provide decent air flow, but i don't know if it provides enough cooling yet... I am still waiting on a longer sensor cable so I can take this thing out for its first run.

I am not a great modeler, so the design is a bit rough (I started with the 40mm fan adapter for the 8s heatsink, so there are some extra holes), but I would be happy to upload the files to thingiverse if anyone wants to try it out.

I am not a great modeler, so the design is a bit rough (I started with the 40mm fan adapter for the 8s heatsink, so there are some extra holes), but I would be happy to upload the files to thingiverse if anyone wants to try it out.