I modded my center driveshaft on my granite to something more than just the plastic piece.

This is fairly cheap (I think), requires minimal extra parts, and the parts are arrma parts so there shouldn't be too much of an issue (other than in-stock) to find these parts.

This is a "mini-tutorial" because you don't have to do exactly as I did but you can get the idea of where to start.

Here's what you should end up with

Parts list:

Slider driveshafts - one set, pick your color

Red

Grey

Slipper Shaft - One

Nero Shaft Boots - One

Bearing 8X16X5 - One, this is the outer wheel bearing for the kraton4s/outcast4s

M3x4MM Hex Head screw - I had this laying around

M3x11MM Counter sink screw - I had this laying around

Center Support - I designed, 3d printed this one for the bearing. You might be able to get away with not having it but if you can find someone to 3d print it I would highly suggest it.

Besides the M3x4MM and M3x11 screws total cost is about $33 before taxes/shipping.

Getting the parts together because there is a few minor modifications we need to do.

The first is the stock slipper shaft from the slipper assembly. Remove the red (short) slipper shaft and remove some material from one end. I took off 1mm from the end and re-inserted the shaft back into the slipper with the cut end facing the front.

Insert one boot onto each of the 80mm sliders. I chose to insert them this way to allow me to still slide the shafts back and forth when installing/removing.

The long slipper shaft will require some new pin holes.

The first one is easy. Slide one slider shaft onto the short end of the slipper shaft until it stops. Drill your pin hole at this spot.

For the second hole it will be on the long end of the slipper shaft. My caliper shifted a bit but basically from the long end to the center of your pin hole is 7.5mm.

Verify your pins are snug enough to stay in without falling out too easily. And that should be it for the cutting. You will need to drill a hole in the chassis though for the center support "lock screw".

The 3d printed piece gets the bearing and the M3x4MM hex head screw. The screw is just a bearing stop.

For installation the M3x4MM screw goes in last to allow the bearing to shift/move while installing the shafts.

Slide the first slider shaft onto the front output shaft.

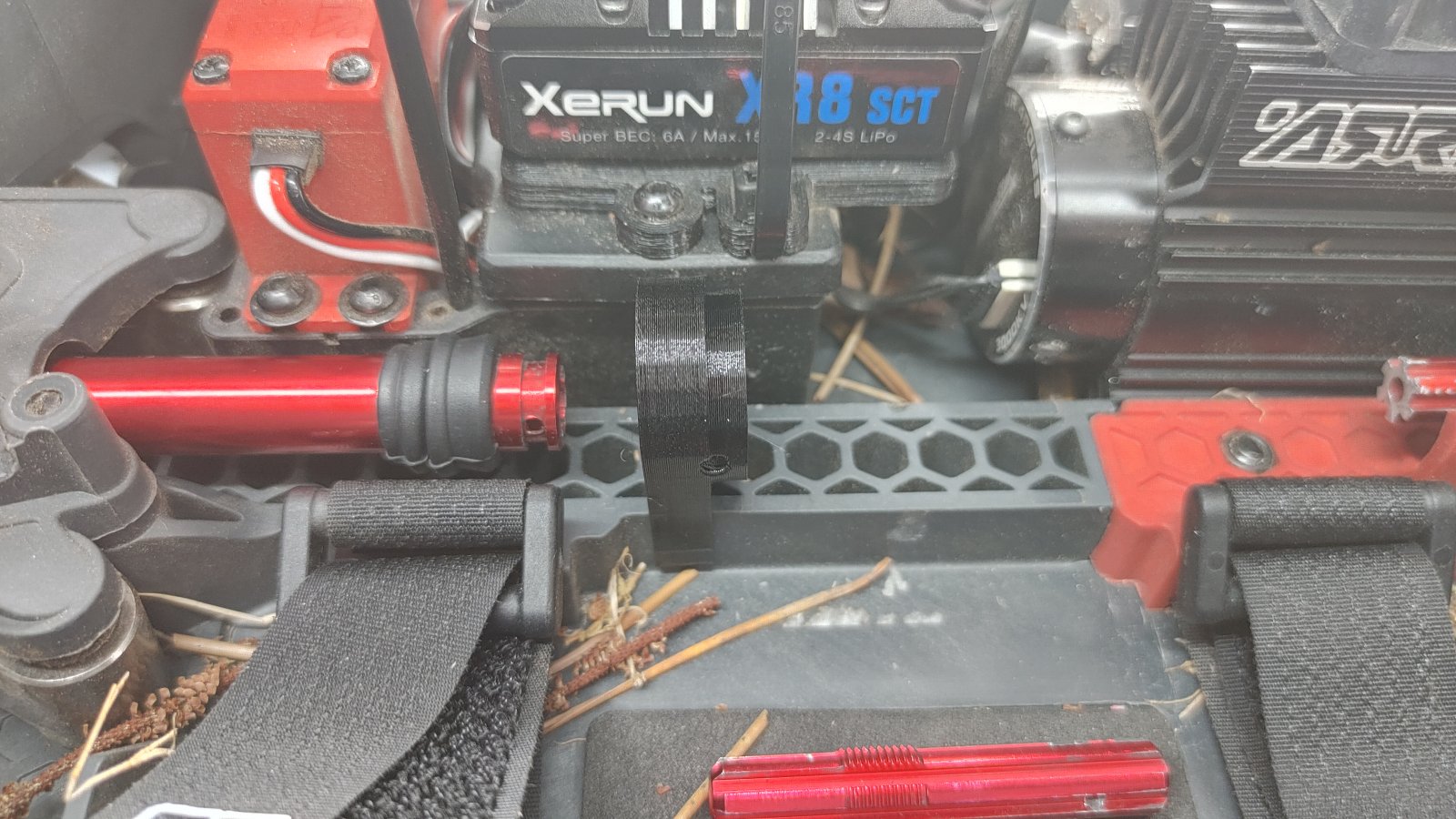

Attach the center support at the marked hole in the orientation shown.

Insert the slipper shaft short end through the center support and into the front slider shaft. Ensure your pin holes are aligned and secure your retaining pin. Cover with the boot.

Continued...

Install the bearing from the other side of the center support until it is bottomed on the other side.

Here's where it gets tight. Insert the second slider shaft onto the center slipper shaft. You will have to persuade it but it will get there.

Once you get the rear slider shaft onto the motor slipper shaft you will have to nudge it back and forth to ensure the front shaft is butted up against the front output section and rear shaft is butted up against the motor slipper. At that point ensure your pin retaining hole for the rear slider shaft is aligned.

Insert your retaining pin and secure with the boot.

Ensure the bearing is still bottomed out and install the M3x4MM retaining screw.

Now secure the center support with the M3x11 counter sink screw. I didn't take a pic of the top part but basically you drill a hole through the part the center support sits in and then drive a screw from the bottom.

And now you have a modded center driveshaft ?

?

This is fairly cheap (I think), requires minimal extra parts, and the parts are arrma parts so there shouldn't be too much of an issue (other than in-stock) to find these parts.

This is a "mini-tutorial" because you don't have to do exactly as I did but you can get the idea of where to start.

Here's what you should end up with

Parts list:

Slider driveshafts - one set, pick your color

Red

Grey

Slipper Shaft - One

Nero Shaft Boots - One

Bearing 8X16X5 - One, this is the outer wheel bearing for the kraton4s/outcast4s

M3x4MM Hex Head screw - I had this laying around

M3x11MM Counter sink screw - I had this laying around

Center Support - I designed, 3d printed this one for the bearing. You might be able to get away with not having it but if you can find someone to 3d print it I would highly suggest it.

Besides the M3x4MM and M3x11 screws total cost is about $33 before taxes/shipping.

Getting the parts together because there is a few minor modifications we need to do.

The first is the stock slipper shaft from the slipper assembly. Remove the red (short) slipper shaft and remove some material from one end. I took off 1mm from the end and re-inserted the shaft back into the slipper with the cut end facing the front.

Insert one boot onto each of the 80mm sliders. I chose to insert them this way to allow me to still slide the shafts back and forth when installing/removing.

The long slipper shaft will require some new pin holes.

The first one is easy. Slide one slider shaft onto the short end of the slipper shaft until it stops. Drill your pin hole at this spot.

For the second hole it will be on the long end of the slipper shaft. My caliper shifted a bit but basically from the long end to the center of your pin hole is 7.5mm.

Verify your pins are snug enough to stay in without falling out too easily. And that should be it for the cutting. You will need to drill a hole in the chassis though for the center support "lock screw".

The 3d printed piece gets the bearing and the M3x4MM hex head screw. The screw is just a bearing stop.

For installation the M3x4MM screw goes in last to allow the bearing to shift/move while installing the shafts.

Slide the first slider shaft onto the front output shaft.

Attach the center support at the marked hole in the orientation shown.

Insert the slipper shaft short end through the center support and into the front slider shaft. Ensure your pin holes are aligned and secure your retaining pin. Cover with the boot.

Continued...

Install the bearing from the other side of the center support until it is bottomed on the other side.

Here's where it gets tight. Insert the second slider shaft onto the center slipper shaft. You will have to persuade it but it will get there.

Once you get the rear slider shaft onto the motor slipper shaft you will have to nudge it back and forth to ensure the front shaft is butted up against the front output section and rear shaft is butted up against the motor slipper. At that point ensure your pin retaining hole for the rear slider shaft is aligned.

Insert your retaining pin and secure with the boot.

Ensure the bearing is still bottomed out and install the M3x4MM retaining screw.

Now secure the center support with the M3x11 counter sink screw. I didn't take a pic of the top part but basically you drill a hole through the part the center support sits in and then drive a screw from the bottom.

And now you have a modded center driveshaft

Last edited: