anthonyslwooko

Active Member

- Messages

- 242

- Reaction score

- 342

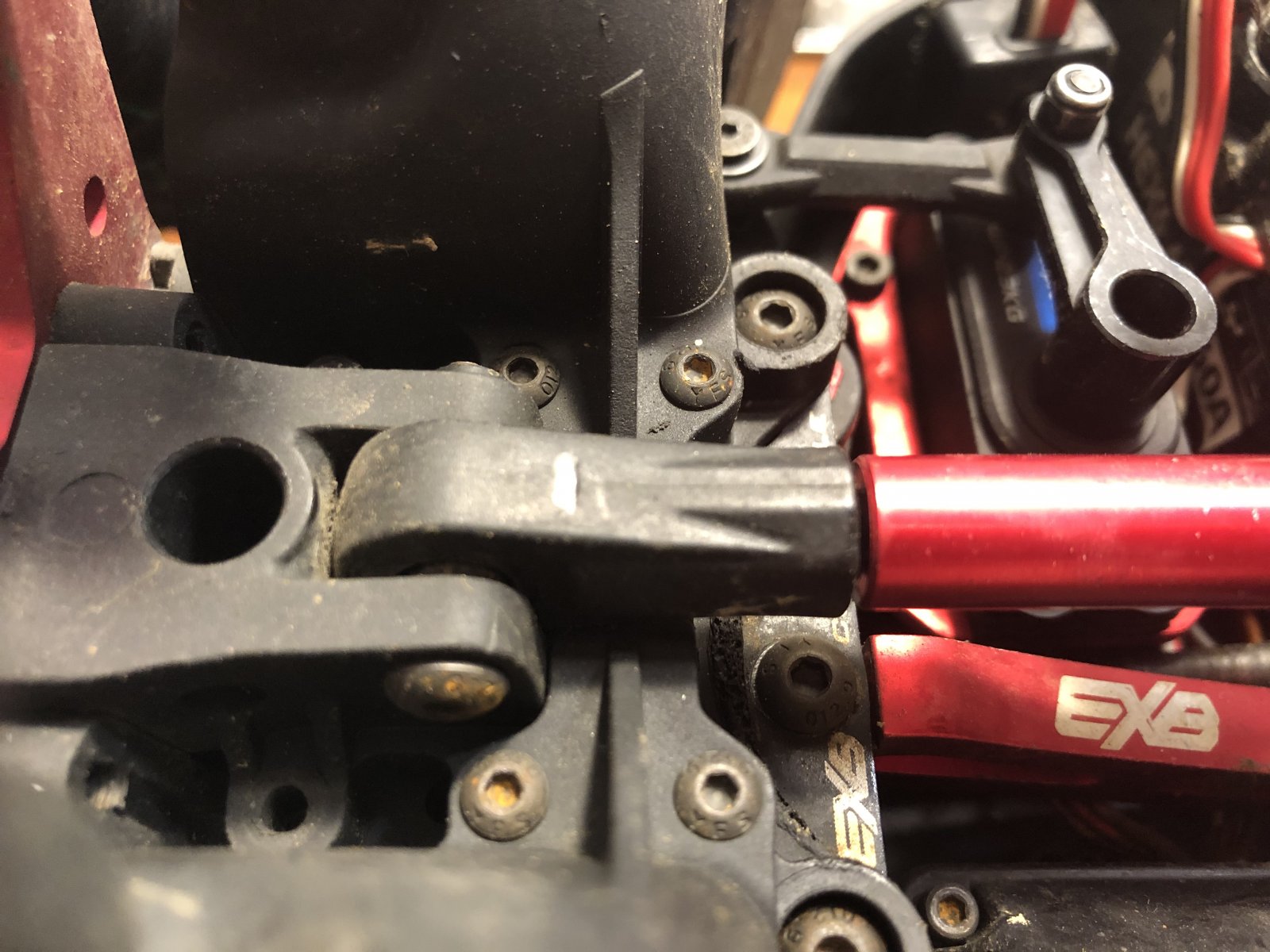

After taking the rear brace and t2t brace off the chassis straightened out. Something else maybe bent then. Anf the chassis has a bunch of flexibility is it ok to extend the t2t for a little more length? And I also sheared the screw holding the rear center brace.