- Messages

- 1,755

- Reaction score

- 3,176

- Location

- Wenatchee, WA

- Arrma RC's

- 4x4-Mega

- BigRock 4x4

- Felony

- Granite

- Infraction

- Limitless

- Kraton 6s

- Outcast 4s

- Typhon 3s

- Voltage

Greetings all,

I wanted to chronicle my build journey in taking my V1 Infraction (which started out as a Limitless) and converting it to a Felony. If you want to see where this build really began you should visit my other build thread found here:

https://www.arrmaforum.com/threads/another-limitless-to-infraction-build.23649/

Now when I say this is converted to a Felony, it's really what I kinda call a "Diet Pepsi" Felony and by that I mean it's got the Felony body panels, but still running the V1 gearing (3.31 ratio) front and rear and matching tires on all 4 corners, so not quite a Felony in terms of what's under the body but close. In order to pull this off there was a few things that needed to be addressed.

So the way I got here was I was browsing jennysrc.com one day and they had just added the Felony parts. I went in and found that the black body kit parts were in stock so I quickly grabbed them up. When they arrived I did an inventory and just so you know Jenny's leaves out a couple of things. For example, the body accessory kit for the turbos/supercharger etc. does NOT include the front mounted intercooler. I don't know if that was left out on accident but my accessories didn't come with it, they sent the rubber tube thing but not the actual intercooler that's able to be mounted. They also forgot one of the little bucket things that I still don't know where they go. I never planned to use the intercooler accessory because I think it looks a little silly so I didn't bother to contact them.

So to start this off I took off parts from the Infraction and then compared them against the different Felony parts that I would be swapping out which was the front splitter, front foam, and adding the front lower body plastic. What I found was that while the front foam and front splitters are different, size wise the foams are very close and you can actually run the stock Infraction foam in the Felony bumper, and the front splitters were also very close and while I didn't try it you could probably get away with running the Infraction front splitter with the Felony body, so just FYI. Other than that the only thing else I needed to change was the Infraction body posts, the fronts needed to be moved from the outside post mounts to the inside mounts and then lowered, and the rear body posts needed the main bar flipped over the other way and body posts raised. I didn't get pics of that but here's the pics of the bumper comparisons:

After swapping the front bumpers and adding the front lower body plastic, I added the rear felony diffuser body panel and exhaust accessory and once I changed the body mounts to accommodate the Felony body I test fitted the body. Everything fit decent except the rear tires looked awkward because they were tucked into the body and looked too small for the rear wheel wells. I expected this because the Felony rear tires are 7mm taller overall and also 10mm wider. In order to make this look right I would need to lower it (combination of droop screw adjustment and lowering the rear body mounts) and also widen the rear stance of the car. To widen the rear there is two ways to go about it: 1.) wider 17mm hexes, or 2.) wider rear hubs/axles/hex adapters.

I know justbashitrc.com carries wider hexes but they are 50 bucks a set which is too rich for my blood. I found these wider hexes on ebay by king-hobby that were advertised to fit the Mojave/Typhon and they looked about right in terms of width so I gave them a shot. When I got them I went to install and afterward I decided it wasn't the way to go for several reasons. 1.) The pin holes for these hexes measure to be 3mm, so with the 2.5mm pins used in the stock axles that left .5mm of play between the pin and the adapters and I didn't like that one bit. I found 3mm pins on Amazon I could use but I didn't want to have to drill out and oversize my axles to make these work because I wanted the ability to switch back to the original hexes. 2.) The wheel nut threading is different, so I was not able to use the stock wheel nuts. The wheel nuts that came with these adapters were smooth on each side so they probably would work themselves loose over time. This was enough to make me scrap the idea and instead try Kraton 6s rear hubs/axles/hexes. Before the Kraton rear swap was known/circulated I had spent my own time researching the current arrma models and gathering specs of the different rear hubs that were available. I found that the Kraton 6s hubs were +7mm wider than the stock Infraction hubs, and the Kraton 6s hexes/axles added another +3mm on top of that giving a total of +10mm additional offset. I sourced the parts between Jenny's and eBay and when they got in I found they fit very nicely. Below is a comparison of each side by side with the stock Infraction just for reference:

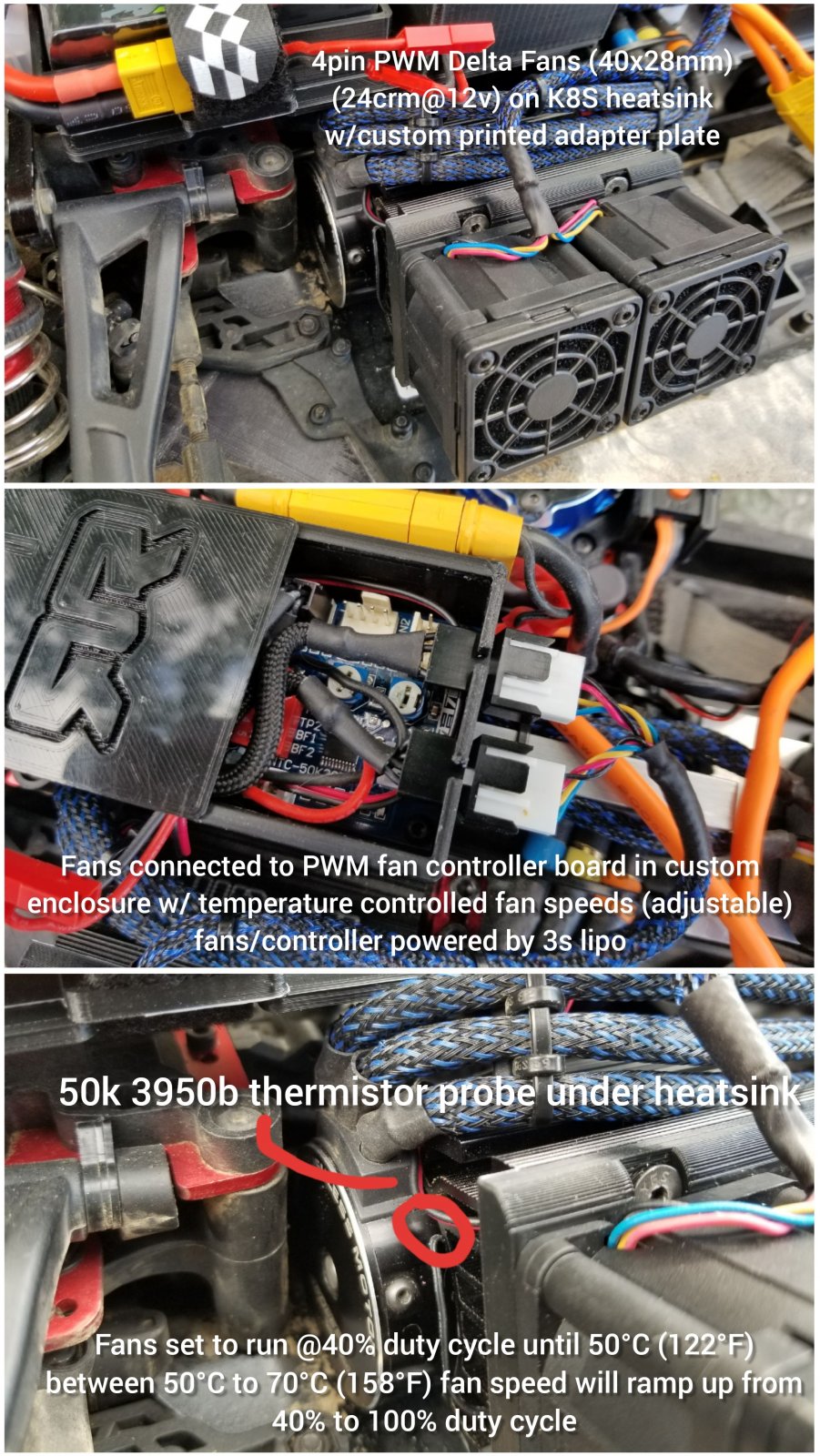

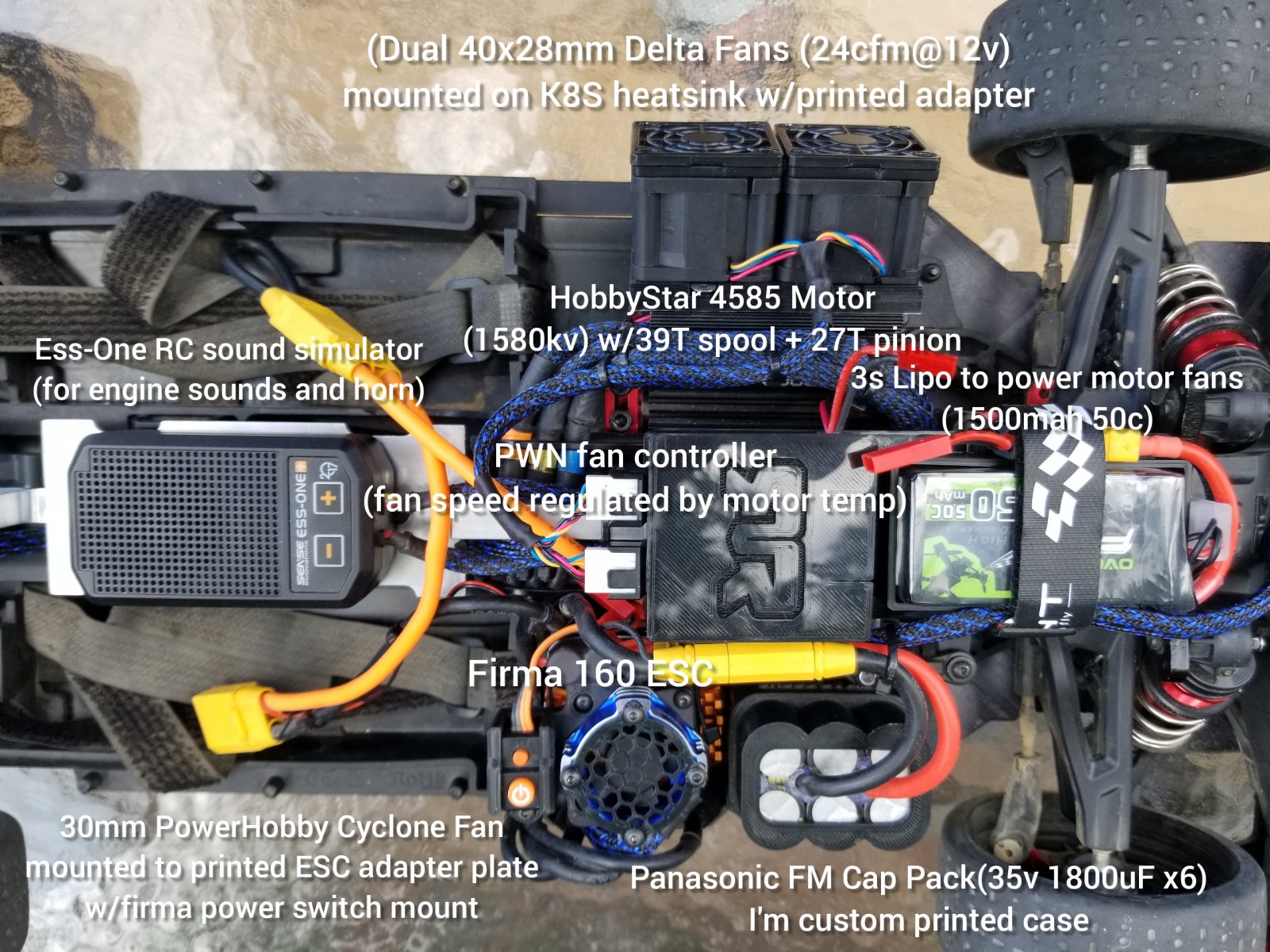

So after getting the body and wheel fitment to look right, I wanted to do some other upgrades to the car. I want to do more intermediate speed running, not trying to break records but fast enough to get my feet wet (100-120mph range). I removed my 22/50 center diff setup and replaced with a 39T spool and 27T pinion. I know that speed running is going to be hard on the motor in terms of heat so I wanted to improve it's cooling capacity. I ordered a bundle of Delta server fans (40x28mm) from eBay for $15.00 for a total set of (4)12v fans rated for 24cfm each. These were 4pin PWM enabled fans which meant it had the ability to have its fan speed governed, so instead of just chopping the extra 2 wires and converting it to a 2pin fan I decided to explore the PWM thing. I found a PWM controller board that was plug and play that would allow me to govern the speed of the fans speeds either via temperature or adjustable potentiometers anywhere from 5% duty cycle to 100% duty cycle. I opted to try the temperature controlled route for now and will be experimenting but in a nutshell I have the controller set to operate the fans at 40% duty cycle (aka 40% max speed) until the sensor probe (inserted between the heatsink and motor) reaches 50°C (122°F), then between 50°C to 70°C (158°F) the fans will ramp up in speed until it hits 100% duty cycle. There are toggles on the control board that allow me to adjust this temperate range but for now I think this is a good place to start and go from there.

Here is a proof of concept video I made showing the fans in action with their speeds increasing with temperature. Note that in the video I have a 12v buck converter I planned to use with the controller in order to just use whatever lipo battery power I was running and converting it to 12v to run the fans and controller, but once I designed a housing for everything it was just too large for my taste and so I ended up going with a small 3s lipo to power it all instead.

Anyways this build thread is getting kind of long so I will just cut to the chase and list all the other things I added:

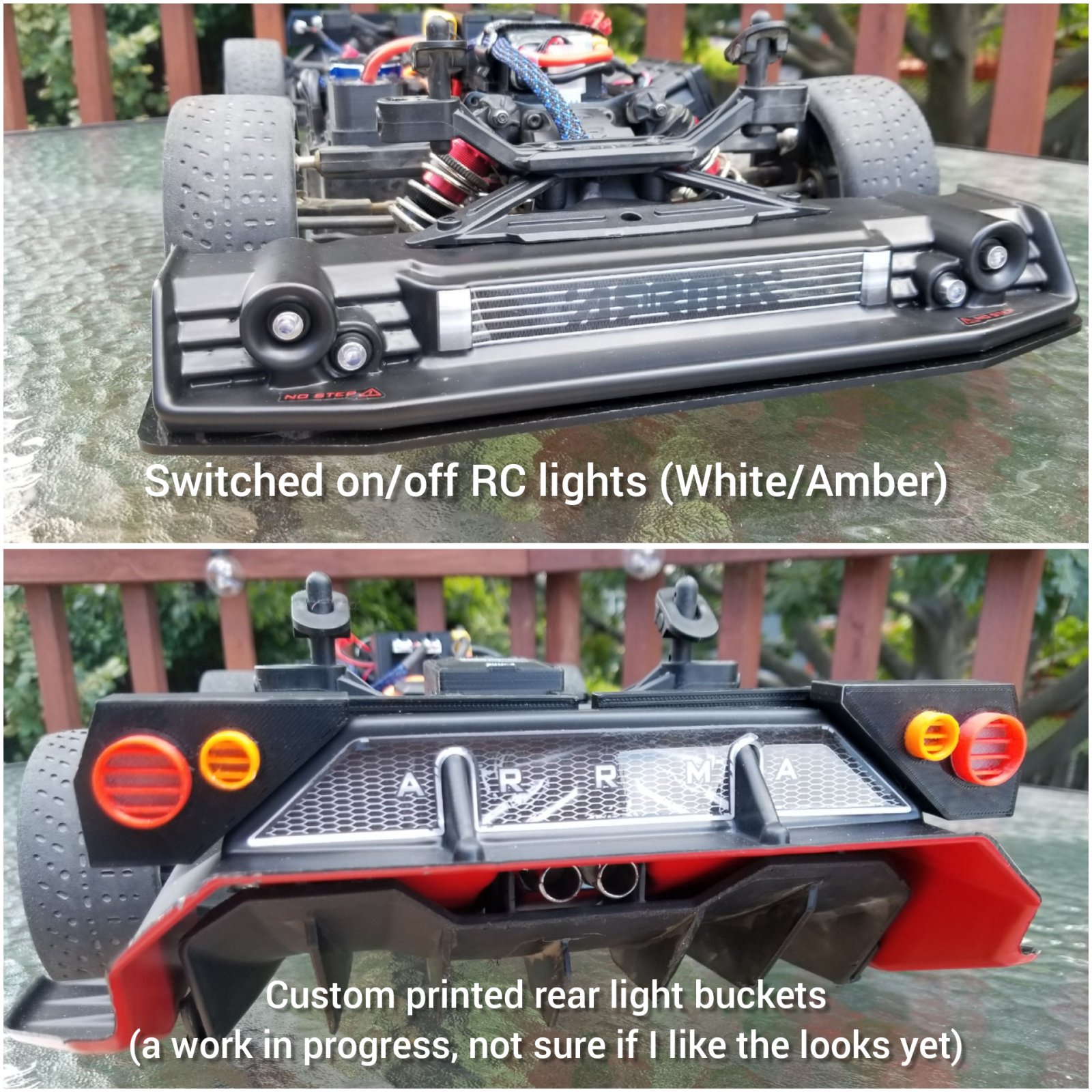

- LED lights front/rear (rear with custom printed buckets), remote switchable

- ESS-One RC sound simulator (engine sounds and horn)

- 10,800uF 35V custom cap pack

- Aluminum eBay center brace w/center mounting tray (needed this to make more real estate under the body for lots of the extra things)

- 3d printed center drive shaft support (dual bearings, designed to work with my 6mm steel rear center driveshaft)

- 30mm PowerHobby "Booster" high cfm fan mounted onto the Firma 160 ESC via printed adapter (adapter has mount for firma power switch included in it) + custom printed fan guard

- SkyRC GSM020 GPS speedometer + printed mount

- Firma 160 8s esc paired with a DX5C for all the telemetry goodness

- lots of other custom designed 3d printed stuff, custom wiring looms/harnesses, etc all over the place to give everything the cleanest fitment I could.

And here's what it looks like at the end with the body on and with the lights. The name "Death Proof" comes from the Tarentino movie of the same name and is a tribute to Kurt Russel's character "Stuntman Mike" and both his murdered out muscle cars he uses to kill people with (a late 60s Chevy Nova and Dodge Charger).

I wanted to chronicle my build journey in taking my V1 Infraction (which started out as a Limitless) and converting it to a Felony. If you want to see where this build really began you should visit my other build thread found here:

https://www.arrmaforum.com/threads/another-limitless-to-infraction-build.23649/

Now when I say this is converted to a Felony, it's really what I kinda call a "Diet Pepsi" Felony and by that I mean it's got the Felony body panels, but still running the V1 gearing (3.31 ratio) front and rear and matching tires on all 4 corners, so not quite a Felony in terms of what's under the body but close. In order to pull this off there was a few things that needed to be addressed.

So the way I got here was I was browsing jennysrc.com one day and they had just added the Felony parts. I went in and found that the black body kit parts were in stock so I quickly grabbed them up. When they arrived I did an inventory and just so you know Jenny's leaves out a couple of things. For example, the body accessory kit for the turbos/supercharger etc. does NOT include the front mounted intercooler. I don't know if that was left out on accident but my accessories didn't come with it, they sent the rubber tube thing but not the actual intercooler that's able to be mounted. They also forgot one of the little bucket things that I still don't know where they go. I never planned to use the intercooler accessory because I think it looks a little silly so I didn't bother to contact them.

So to start this off I took off parts from the Infraction and then compared them against the different Felony parts that I would be swapping out which was the front splitter, front foam, and adding the front lower body plastic. What I found was that while the front foam and front splitters are different, size wise the foams are very close and you can actually run the stock Infraction foam in the Felony bumper, and the front splitters were also very close and while I didn't try it you could probably get away with running the Infraction front splitter with the Felony body, so just FYI. Other than that the only thing else I needed to change was the Infraction body posts, the fronts needed to be moved from the outside post mounts to the inside mounts and then lowered, and the rear body posts needed the main bar flipped over the other way and body posts raised. I didn't get pics of that but here's the pics of the bumper comparisons:

After swapping the front bumpers and adding the front lower body plastic, I added the rear felony diffuser body panel and exhaust accessory and once I changed the body mounts to accommodate the Felony body I test fitted the body. Everything fit decent except the rear tires looked awkward because they were tucked into the body and looked too small for the rear wheel wells. I expected this because the Felony rear tires are 7mm taller overall and also 10mm wider. In order to make this look right I would need to lower it (combination of droop screw adjustment and lowering the rear body mounts) and also widen the rear stance of the car. To widen the rear there is two ways to go about it: 1.) wider 17mm hexes, or 2.) wider rear hubs/axles/hex adapters.

I know justbashitrc.com carries wider hexes but they are 50 bucks a set which is too rich for my blood. I found these wider hexes on ebay by king-hobby that were advertised to fit the Mojave/Typhon and they looked about right in terms of width so I gave them a shot. When I got them I went to install and afterward I decided it wasn't the way to go for several reasons. 1.) The pin holes for these hexes measure to be 3mm, so with the 2.5mm pins used in the stock axles that left .5mm of play between the pin and the adapters and I didn't like that one bit. I found 3mm pins on Amazon I could use but I didn't want to have to drill out and oversize my axles to make these work because I wanted the ability to switch back to the original hexes. 2.) The wheel nut threading is different, so I was not able to use the stock wheel nuts. The wheel nuts that came with these adapters were smooth on each side so they probably would work themselves loose over time. This was enough to make me scrap the idea and instead try Kraton 6s rear hubs/axles/hexes. Before the Kraton rear swap was known/circulated I had spent my own time researching the current arrma models and gathering specs of the different rear hubs that were available. I found that the Kraton 6s hubs were +7mm wider than the stock Infraction hubs, and the Kraton 6s hexes/axles added another +3mm on top of that giving a total of +10mm additional offset. I sourced the parts between Jenny's and eBay and when they got in I found they fit very nicely. Below is a comparison of each side by side with the stock Infraction just for reference:

So after getting the body and wheel fitment to look right, I wanted to do some other upgrades to the car. I want to do more intermediate speed running, not trying to break records but fast enough to get my feet wet (100-120mph range). I removed my 22/50 center diff setup and replaced with a 39T spool and 27T pinion. I know that speed running is going to be hard on the motor in terms of heat so I wanted to improve it's cooling capacity. I ordered a bundle of Delta server fans (40x28mm) from eBay for $15.00 for a total set of (4)12v fans rated for 24cfm each. These were 4pin PWM enabled fans which meant it had the ability to have its fan speed governed, so instead of just chopping the extra 2 wires and converting it to a 2pin fan I decided to explore the PWM thing. I found a PWM controller board that was plug and play that would allow me to govern the speed of the fans speeds either via temperature or adjustable potentiometers anywhere from 5% duty cycle to 100% duty cycle. I opted to try the temperature controlled route for now and will be experimenting but in a nutshell I have the controller set to operate the fans at 40% duty cycle (aka 40% max speed) until the sensor probe (inserted between the heatsink and motor) reaches 50°C (122°F), then between 50°C to 70°C (158°F) the fans will ramp up in speed until it hits 100% duty cycle. There are toggles on the control board that allow me to adjust this temperate range but for now I think this is a good place to start and go from there.

Here is a proof of concept video I made showing the fans in action with their speeds increasing with temperature. Note that in the video I have a 12v buck converter I planned to use with the controller in order to just use whatever lipo battery power I was running and converting it to 12v to run the fans and controller, but once I designed a housing for everything it was just too large for my taste and so I ended up going with a small 3s lipo to power it all instead.

Anyways this build thread is getting kind of long so I will just cut to the chase and list all the other things I added:

- LED lights front/rear (rear with custom printed buckets), remote switchable

- ESS-One RC sound simulator (engine sounds and horn)

- 10,800uF 35V custom cap pack

- Aluminum eBay center brace w/center mounting tray (needed this to make more real estate under the body for lots of the extra things)

- 3d printed center drive shaft support (dual bearings, designed to work with my 6mm steel rear center driveshaft)

- 30mm PowerHobby "Booster" high cfm fan mounted onto the Firma 160 ESC via printed adapter (adapter has mount for firma power switch included in it) + custom printed fan guard

- SkyRC GSM020 GPS speedometer + printed mount

- Firma 160 8s esc paired with a DX5C for all the telemetry goodness

- lots of other custom designed 3d printed stuff, custom wiring looms/harnesses, etc all over the place to give everything the cleanest fitment I could.

And here's what it looks like at the end with the body on and with the lights. The name "Death Proof" comes from the Tarentino movie of the same name and is a tribute to Kurt Russel's character "Stuntman Mike" and both his murdered out muscle cars he uses to kill people with (a late 60s Chevy Nova and Dodge Charger).

Last edited: