- Messages

- 171

- Reaction score

- 194

- Arrma RC's

- Typhon 3s

hey!

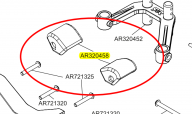

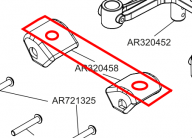

Is there anyone willing to design a modified ARRMA part part for me?

I guess the 3D file of the original part would become handy to start with, but I'm not sure if it's available (I've asked Arrma in the meantime)

I don't know much of 3d printing stuff but I my guess my idea is pretty easy stuff

I'll give more details of course!

Let me know!

Is there anyone willing to design a modified ARRMA part part for me?

I guess the 3D file of the original part would become handy to start with, but I'm not sure if it's available (I've asked Arrma in the meantime)

I don't know much of 3d printing stuff but I my guess my idea is pretty easy stuff

I'll give more details of course!

Let me know!