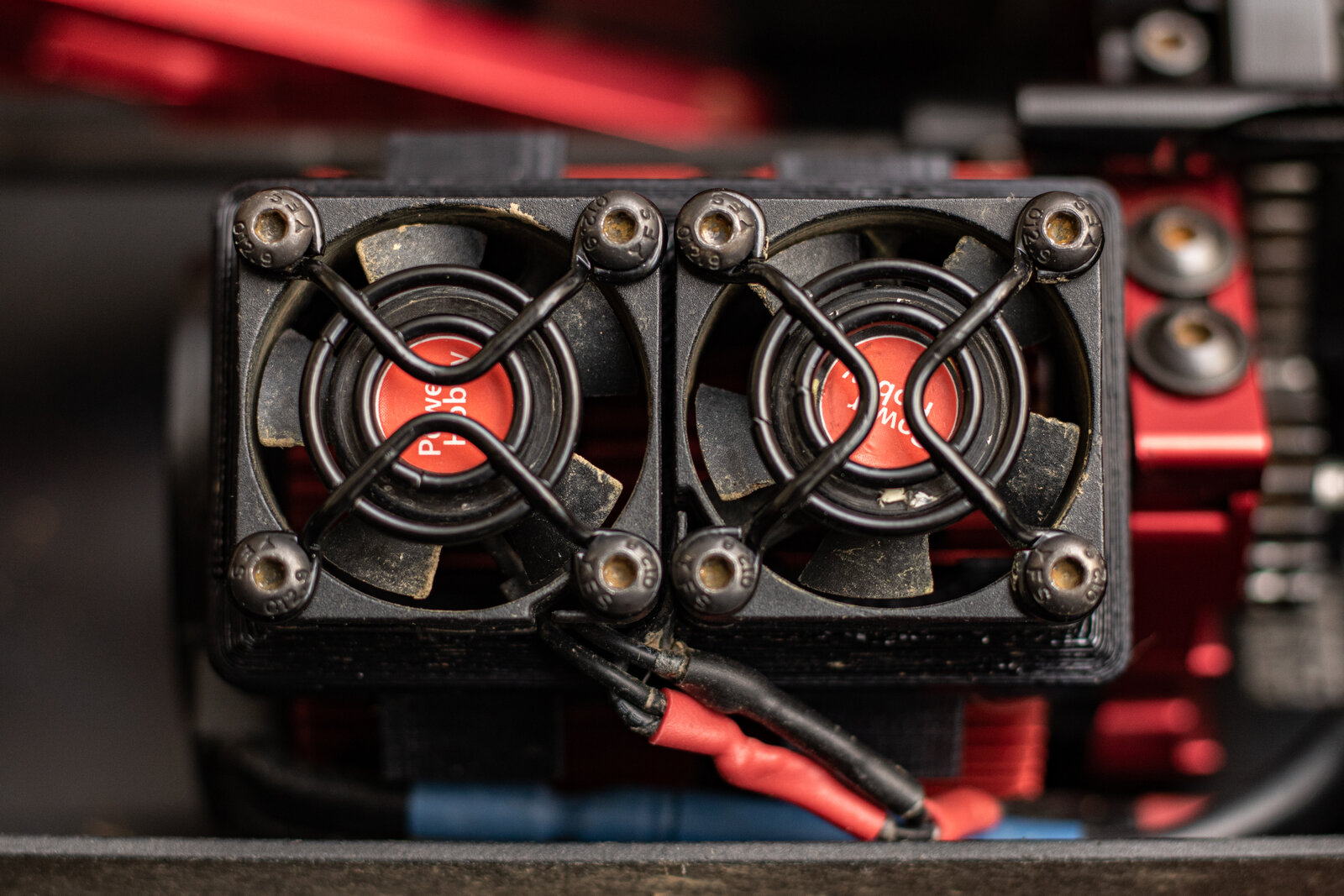

I got the Powerhobby twin fan heat sink for my Mojave and immediately noticed some things about it I didn't like. The fans don't have enough "breathing room" as in the heat sink fins are very shallow and don't allow for much air flow at all, effectively choking the fans. The fans do come with spacers to increase their output but doing this doesn't force much of the air to go through the fins or the opening under the fins where it's supposed to vent along the motor case. Another thing I noticed (this may have just been a manufacturing defect with mine) was that the mounting holes for the fans placed them to tightly with each other. It was almost impossible to get four screws in each fan because the holes weren't lining up. The product did a better job at cooling then the stock heat sink or nothing at all but it was bugging me knowing the fans were getting choked. What I did was make a two piece Powerhobby heat sink manifold, this completely fixed the problems I was having with the heat sink. The first piece (the heat sink adapter) uses fan screws to be attached to the heat sink, this piece directs the air over the fins and down over the edge onto the motor ends, it also has four side ports that blow air over the side heat sinks (one of the four side ports is shorter to fit better beside the center brace for the Mojave body). The adapter plate screw holes are all oval shape so you can adjust the airflow to either be even or adjust it so there is more airflow over the front or rear motor bells. The second piece (the lid) is attached over the first piece and is the mount for the fans and spaces the fans out better so they're not being jammed together, the little extra space also gives enough room to put on fan grills to protect the blades (and fingers). I am currently working on the lid to make it so it just snaps on to the adapter but as of right now I just put a very small dab of super glue on the four corners of the lid to hold it on and so far it's been doing great. After making and using this manifold my temps have fallen a great bit, with the heat sink set with factory specs the motor was still warm to the touch but after the manifold was attached the motor is cooler even with a larger pinion! Check out the pictures below to see how it works and thanks for reading! If any one would like to download the STL files you can get them here ---> https://www.thingiverse.com/thing:4750717

Last edited: