Papa_smurf

Member

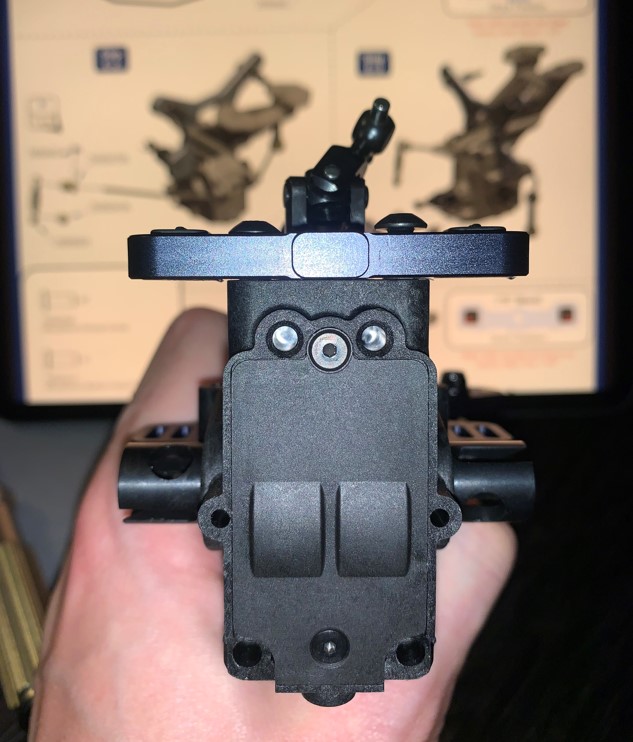

Got started on my EB48 2.0 build to accompany my Big Rock! This is my first kit build though I've pretty much completely disassembled & reassembled my Big Rock.

- The diff builds went nice and smooth. Quality seems awesome to me!

-

- The front & rear diff housings went MOSTLY smooth....some of the screws were punishing on the hands to get tight