Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Outcast Edward's NEW 1/5 Outcast Project

- Thread starter Siggy

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

Reubydoobe

Reuby Doobe

- Messages

- 1,622

- Reaction score

- 6,213

- Arrma RC's

- Mojave

- Notorious

- Outcast 6s

- Talion

- Typhon 6s

I'm not sure about that, I think a shim behind the c clip will help

Siggy

Active Member

- Thread starter

- #65

You can try doing that, if it eliminates the "bind" between diff case and pinion, especially if what caused those scratched is the "play" of the pinion. But you'll have to start with a set of thin shims to fine-tune so as not to to cause the pinion to tighten-up and bind the bearings. MAYBE, It may also be some dirt between the bearings or the bearings itself lightly narrowed/deformed, due to "normal use" in between HD aluminium rather than plastic -- causing the increase in play of the pinion. Now we sound like Rocket Scientist figuring out what went wrong.

KevinC

Flyboy, Cat Hoarder, Tiger Tamer, Party Crasher.

Lifetime Premium!

Premium Member

Build Thread Contributor

- Messages

- 2,346

- Reaction score

- 4,034

- Location

- Brantford,Ontario

- Arrma RC's

- Fireteam

- Limitless

- Kraton 8S

- Kraton 6s

- Kraton EXB

- Mojave EXB

- Talion

- Talion EXB

I just received these cups a few days back but not installed.

@Reubydoobe keep us posted on the results if you can find a fix.

cheers,

kev

@Reubydoobe keep us posted on the results if you can find a fix.

cheers,

kev

Reubydoobe

Reuby Doobe

- Messages

- 1,622

- Reaction score

- 6,213

- Arrma RC's

- Mojave

- Notorious

- Outcast 6s

- Talion

- Typhon 6s

I'll try a shim and see how it goes. They are a little bit more than scratches though the aluminium has worn away, the edges have gone all round the cup. It feels free when fitted so I'm thinking it only happens at certain time's when there is pressure on the chassis maybeI just received these cups a few days back but not installed.

@Reubydoobe keep us posted on the results if you can find a fix.

cheers,

kev

Reubydoobe

Reuby Doobe

- Messages

- 1,622

- Reaction score

- 6,213

- Arrma RC's

- Mojave

- Notorious

- Outcast 6s

- Talion

- Typhon 6s

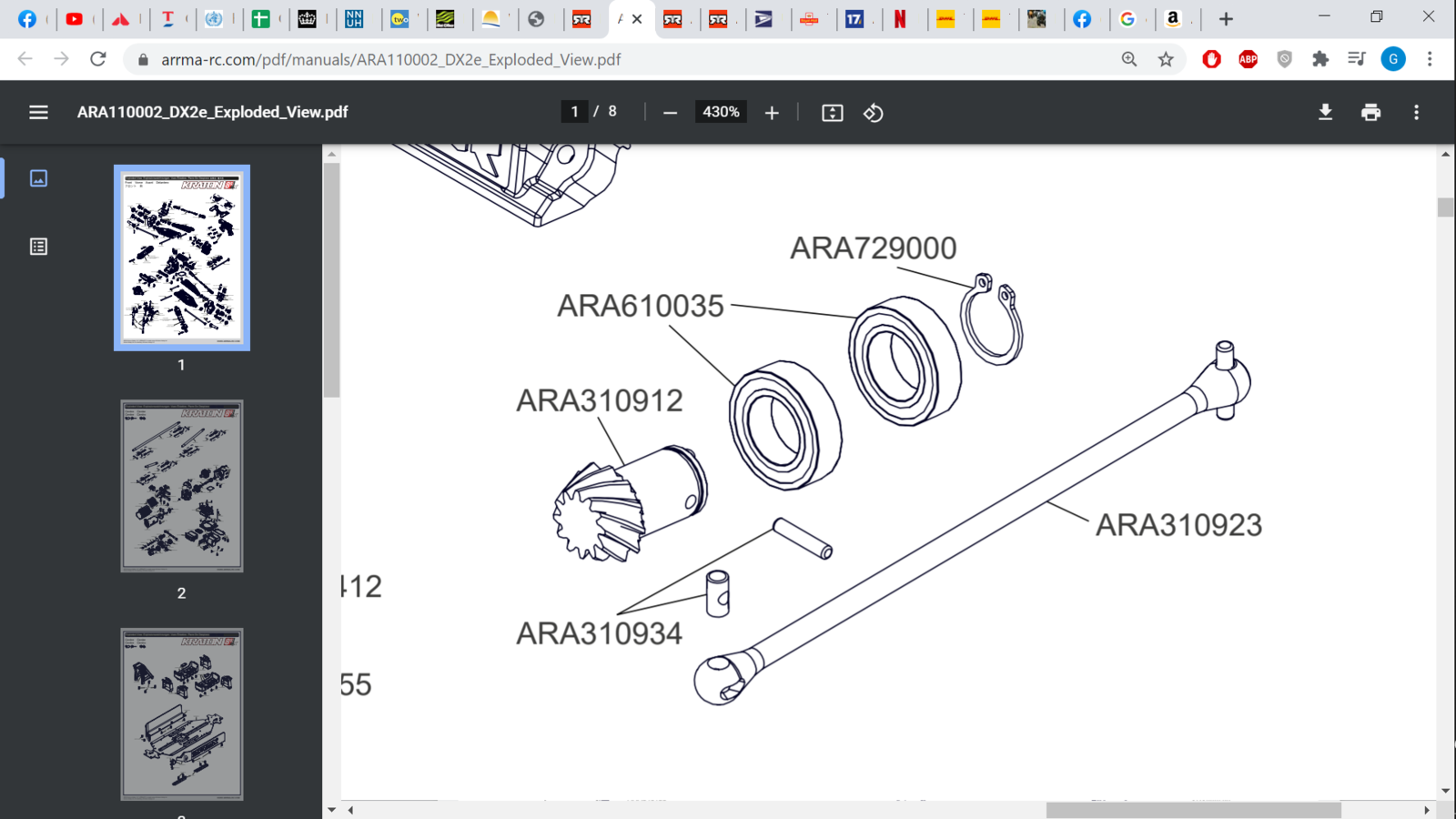

HI, I've tried it all in the new gearbox and this is what I have found out, I put red sharpie on the top of the input shaft/gear so if any rubbing is happening I can see which bit because the red ink would be marked. The gear does move backwards and forwards quite a bit 3 or 4mm maybe when it's in the most forward position ie closer to the dif cup I think the edge of the gear is catching the dif cup edge's as seen in the picture. I don't think it happens all the time because you can see its not touching from the bottom of gearbox when it's in tight. A shim would work either behind the washer or in front of the c clip. My question what size shim do I need to search for? The pack of 8th scale shims I have in my part's bin isn't big enoughYou can try doing that, if it eliminates the "bind" between diff case and pinion, especially if what caused those scratched is the "play" of the pinion. But you'll have to start with a set of thin shims to fine-tune so as not to to cause the pinion to tighten-up and bind the bearings. MAYBE, It may also be some dirt between the bearings or the bearings itself lightly narrowed/deformed, due to "normal use" in between HD aluminium rather than plastic -- causing the increase in play of the pinion. Now we sound like Rocket Scientist figuring out what went wrong.

View attachment 124249

The thing I have noticed is that the top of the shaft isn't very straight one side seems to stick out more than the other and I was wondering if that might be the cause of the problem. I'm considering making it flat but I'm not sure if that might cause problems with the gear. I have an old input shaft somewhere so I will fit that and see if it's the same.

werner sline

Active Member

- Messages

- 138

- Reaction score

- 663

top stuff

Last edited:

Hammer Down

I am serious, and don’t call me Shirley! 🙃

Premium Member

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 8,372

- Reaction score

- 21,436

- Arrma RC's

- Granite Grom

- Infraction

- Limitless

- Kraton 8S

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Outcast 8s

- Infraction 4x4