- Messages

- 1,755

- Reaction score

- 3,176

- Location

- Wenatchee, WA

- Arrma RC's

- 4x4-Mega

- BigRock 4x4

- Felony

- Granite

- Infraction

- Limitless

- Kraton 6s

- Outcast 4s

- Typhon 3s

- Voltage

I just now got done with installing the Ender Extender 300 kit for the Ender 3 Pro and this required a bit more work than just slapping on the longer parts. Since there is a bit more to it than that I wrote this up so people will have a better idea on what to expect before buying one of these kits.

Kit Contents:

Assembly:

After taking a parts inventory I noticed there were no instructions, just a piece of paper that says to go find the instructions on their website. I go to the website and they don't have any instructions for the 300x300 kit, but they have instructions for the 400x400 kit so I use those. Most of the instructions from the 400x400 kit worked but for some stuff they don't.

Y-Axis Rail:

The y-axis rail isn't drilled to be in a fixed position like on the Ender 3, it actually can slide back and forth and attaches via t-nuts in the rail channels. The 400x400 instructions specifically says how many millimeters the rail should measure from the rear to the base rail to perfectly center the bed travel for front/back, however since I have the 300x300 kit the measurement given is wrong. I had to do some eyeballing and measuring of my own until I finally got the rail in the right position with a combination of rail positioning and relocation of the end stop switch. This was a pain in the @ss so just a heads up.

Front/rear base rails:

The kit gets rid of the ender 3 center frame base and replaces it with front/rear rails for bracing. These installed fine on the front but the rear sucked because my ender 3 pro side base rails didn't have screw threading on the rear, only threading in the front. I ended up having to use a thread tap and a bench vise to thread the holes needed for the rear brace to complete the base extension assembly.

Besides those two things the rest of the assembly was pretty straight forward. If I had to mention any other challenges I encountered it would be the difficulty in doing all this part swapping with all the electronics wiring still in place, it gets to be a mess pretty quickly.

Updating Firmware and Slicer:

In order for the printer to know it's got a larger build area you will need to download the latest firmware build files from Marlin or your specific board's github, modify the firmware in a compiler (I used VSCODE with PlatformIO IDE add-on) and change the build surface size in the firmware code. You will also need to configure any other specific features you have installed on your printer (bltouch, higher temp threshold for upgraded hot ends, filament run-out sensor, octoprint, wifi, etc). Once done you compile the firmware then flash it to your printer and hope it all works.

This probably the hardest part for people who haven't done any of this before and even more difficult for people not familiar with coding. I highly recommend you do some homework first and get familiar with how to do this yourself before investing in one of these kits, or get a friend who knows what they are doing, lol.

After setting up and flashing my firmware the last thing I needed to do was to change the bed size in my slicer (I use Cura). This is pretty easy and after finished that I did final printer calibrations (PID calibration for hot end and bed, z-offset for bltouch, and auto bed leveling baseline).

Testing the Printer:

Overall everything was working and after a little tweaking here and there I got everything dialed in. There is one flaw I thought I should mention:

This kit reuses the oem aluminum build plate parts and just bolts a larger plate on top of it. I noticed that when I start a print the oem bed reaches target temp but the added plate and glass I have on top are still very cold and not up to temp yet. Basically the larger surface needs more time to heat up so to account for this I added an additional start up G code in Cura that makes the printer wait an additional 3 minutes after it reaching target bed temp. This is a workaround but so far has worked well for me.

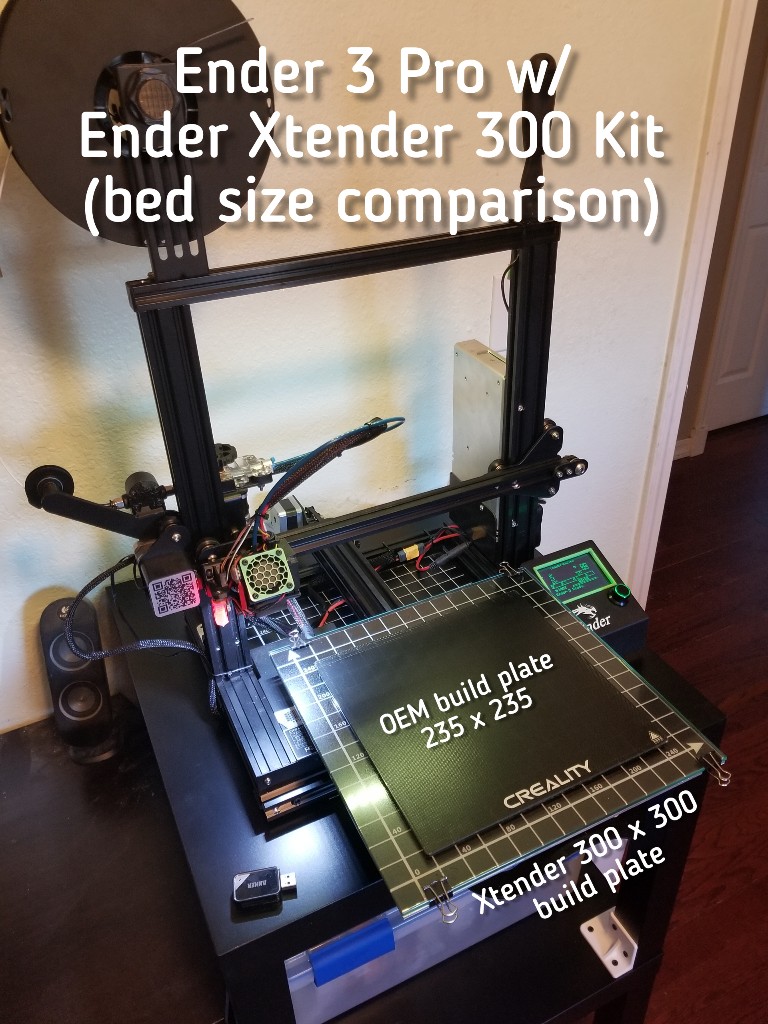

Anyways that's pretty much it. Pics attached for visual reference on differences before/after.

Kit Contents:

- (2) front/rear 20x20mm extended base rails

- (1) 40x40mm extended y-axis rail

- (1) 20x20mm extended x-axis gantry rail

- (1) 20x20mm extended top rail

- (1) 300x300 larger aluminum plate/adapter

- (2) bags of misc bolts/t-nuts/washers

Assembly:

After taking a parts inventory I noticed there were no instructions, just a piece of paper that says to go find the instructions on their website. I go to the website and they don't have any instructions for the 300x300 kit, but they have instructions for the 400x400 kit so I use those. Most of the instructions from the 400x400 kit worked but for some stuff they don't.

Y-Axis Rail:

The y-axis rail isn't drilled to be in a fixed position like on the Ender 3, it actually can slide back and forth and attaches via t-nuts in the rail channels. The 400x400 instructions specifically says how many millimeters the rail should measure from the rear to the base rail to perfectly center the bed travel for front/back, however since I have the 300x300 kit the measurement given is wrong. I had to do some eyeballing and measuring of my own until I finally got the rail in the right position with a combination of rail positioning and relocation of the end stop switch. This was a pain in the @ss so just a heads up.

Front/rear base rails:

The kit gets rid of the ender 3 center frame base and replaces it with front/rear rails for bracing. These installed fine on the front but the rear sucked because my ender 3 pro side base rails didn't have screw threading on the rear, only threading in the front. I ended up having to use a thread tap and a bench vise to thread the holes needed for the rear brace to complete the base extension assembly.

Besides those two things the rest of the assembly was pretty straight forward. If I had to mention any other challenges I encountered it would be the difficulty in doing all this part swapping with all the electronics wiring still in place, it gets to be a mess pretty quickly.

Updating Firmware and Slicer:

In order for the printer to know it's got a larger build area you will need to download the latest firmware build files from Marlin or your specific board's github, modify the firmware in a compiler (I used VSCODE with PlatformIO IDE add-on) and change the build surface size in the firmware code. You will also need to configure any other specific features you have installed on your printer (bltouch, higher temp threshold for upgraded hot ends, filament run-out sensor, octoprint, wifi, etc). Once done you compile the firmware then flash it to your printer and hope it all works.

This probably the hardest part for people who haven't done any of this before and even more difficult for people not familiar with coding. I highly recommend you do some homework first and get familiar with how to do this yourself before investing in one of these kits, or get a friend who knows what they are doing, lol.

After setting up and flashing my firmware the last thing I needed to do was to change the bed size in my slicer (I use Cura). This is pretty easy and after finished that I did final printer calibrations (PID calibration for hot end and bed, z-offset for bltouch, and auto bed leveling baseline).

Testing the Printer:

Overall everything was working and after a little tweaking here and there I got everything dialed in. There is one flaw I thought I should mention:

This kit reuses the oem aluminum build plate parts and just bolts a larger plate on top of it. I noticed that when I start a print the oem bed reaches target temp but the added plate and glass I have on top are still very cold and not up to temp yet. Basically the larger surface needs more time to heat up so to account for this I added an additional start up G code in Cura that makes the printer wait an additional 3 minutes after it reaching target bed temp. This is a workaround but so far has worked well for me.

Anyways that's pretty much it. Pics attached for visual reference on differences before/after.

Last edited: