Tex Koder

2D , 3D Not a problem. I'll take that Challenge.

Lifetime Premium!

Premium Member

ArrmaForum Fan

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 9,944

- Reaction score

- 24,966

- Location

- Dallas, TX (USA)

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Mojave

- Nero

- Senton 3s

- Typhon 6s

- Vendetta

Here's my solution to help remedy the problems of 3S / 4S Chassis from cracking due to slamming of the motor against the chassis from a hard landing. It'll also helps with the motor mounting plate from bending due to similar reasons. Which causes chewed up spur gears in the 3S models.

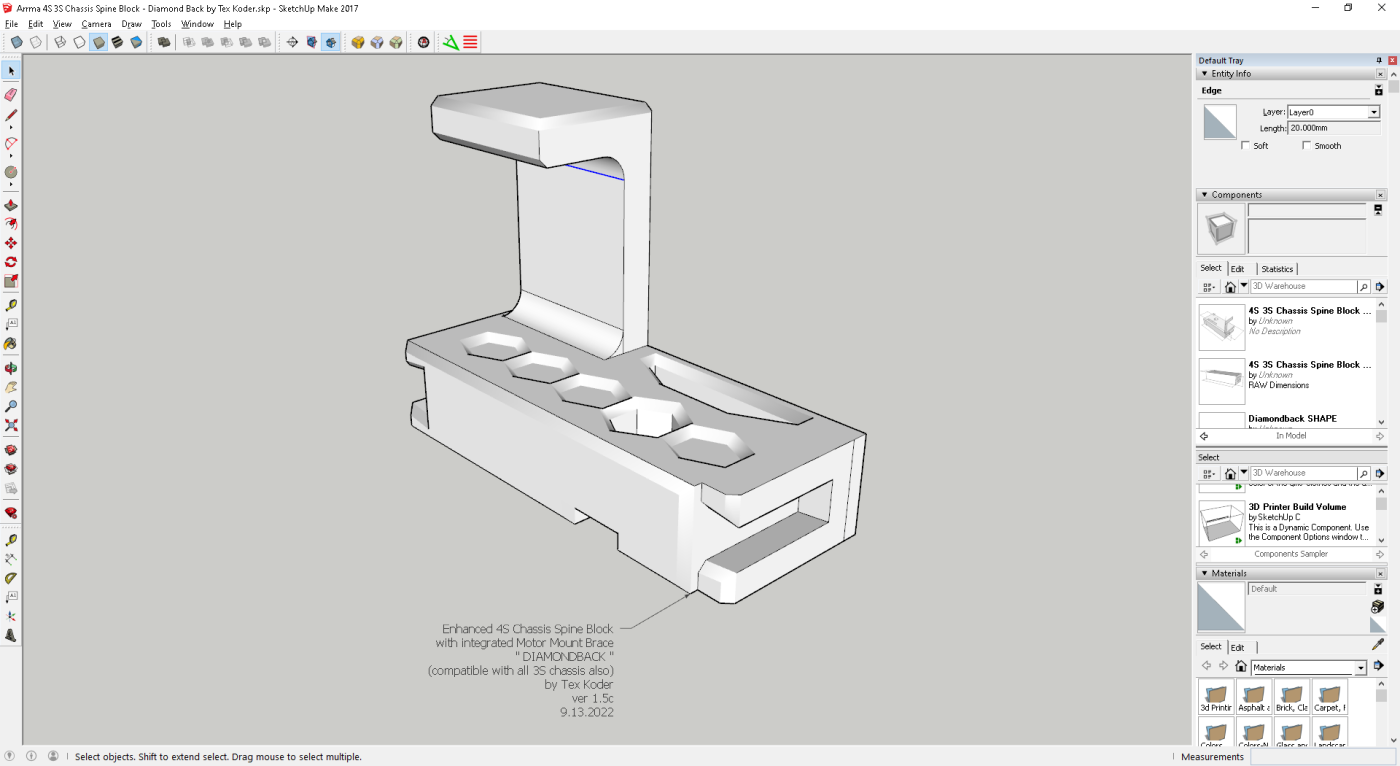

It completely replaces the stock OEM Chassis Spine Block (CSB) with my enchanced design to stiffens up the power module to chassis "interface" -by providing a simple and effective integrated brace.

I call it - DiamondBack

Original rough sketches >

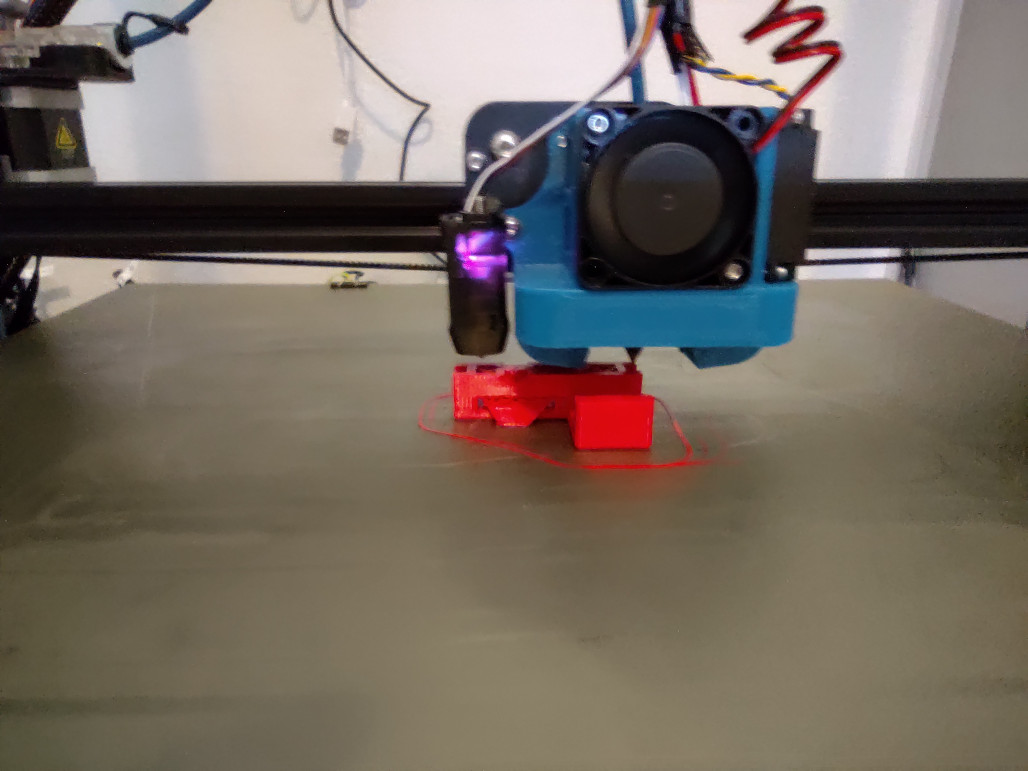

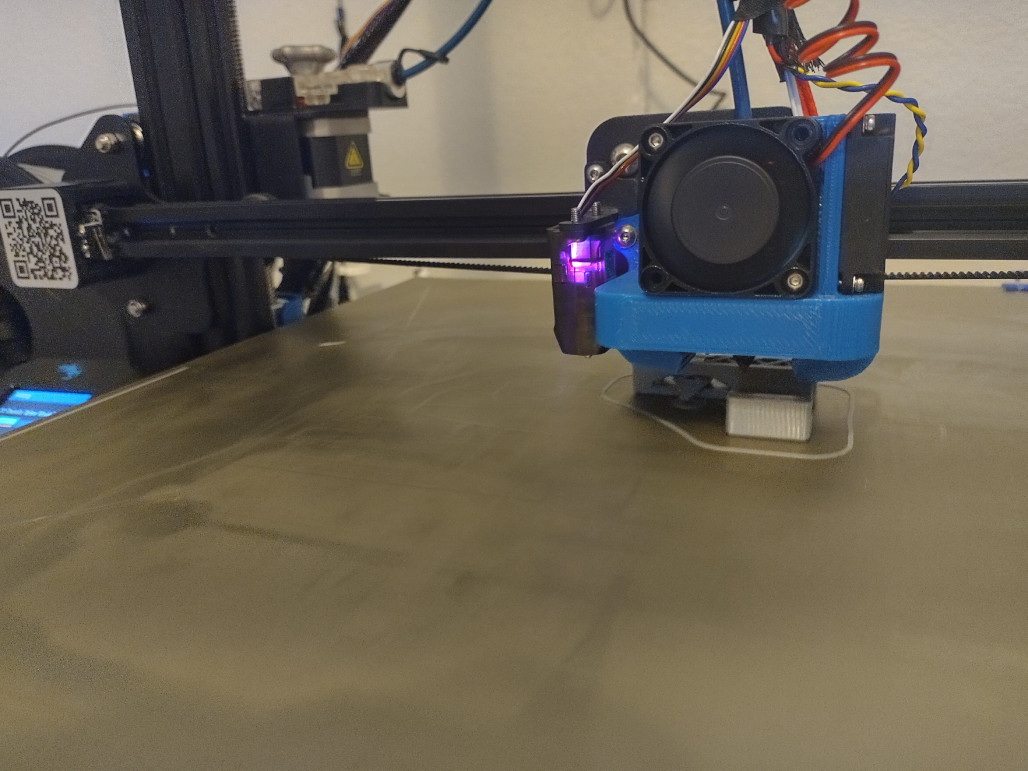

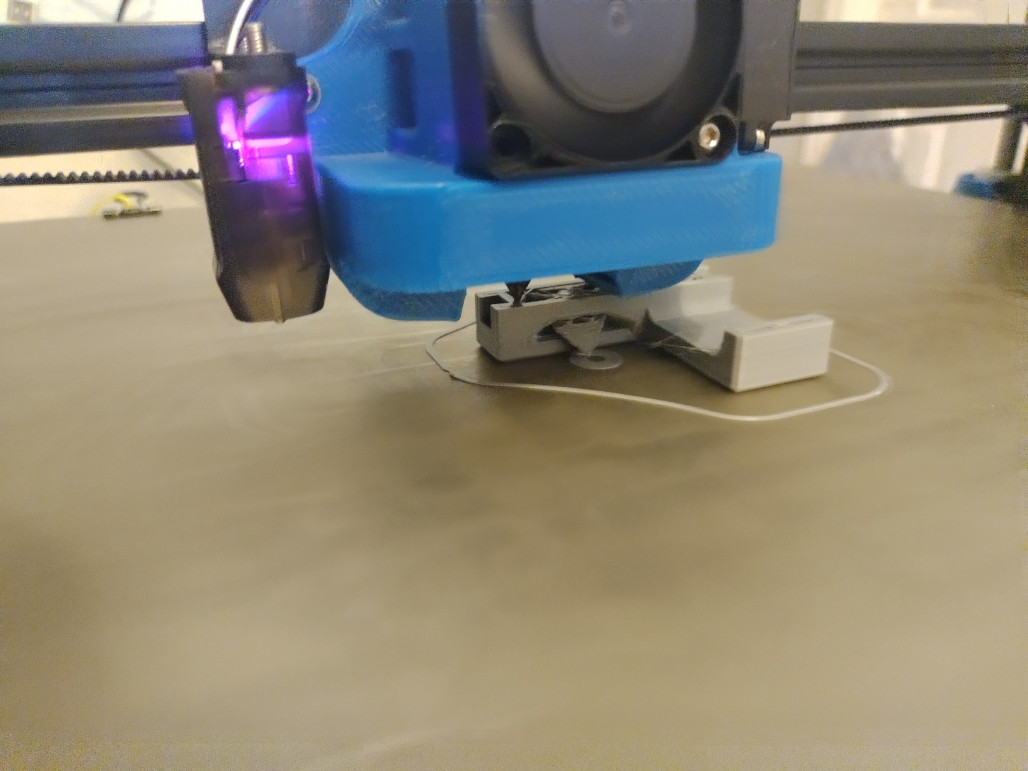

Original Test Prints >

Some tweaks were needed to get the fitment right ,plus some refinement to the details of the design...

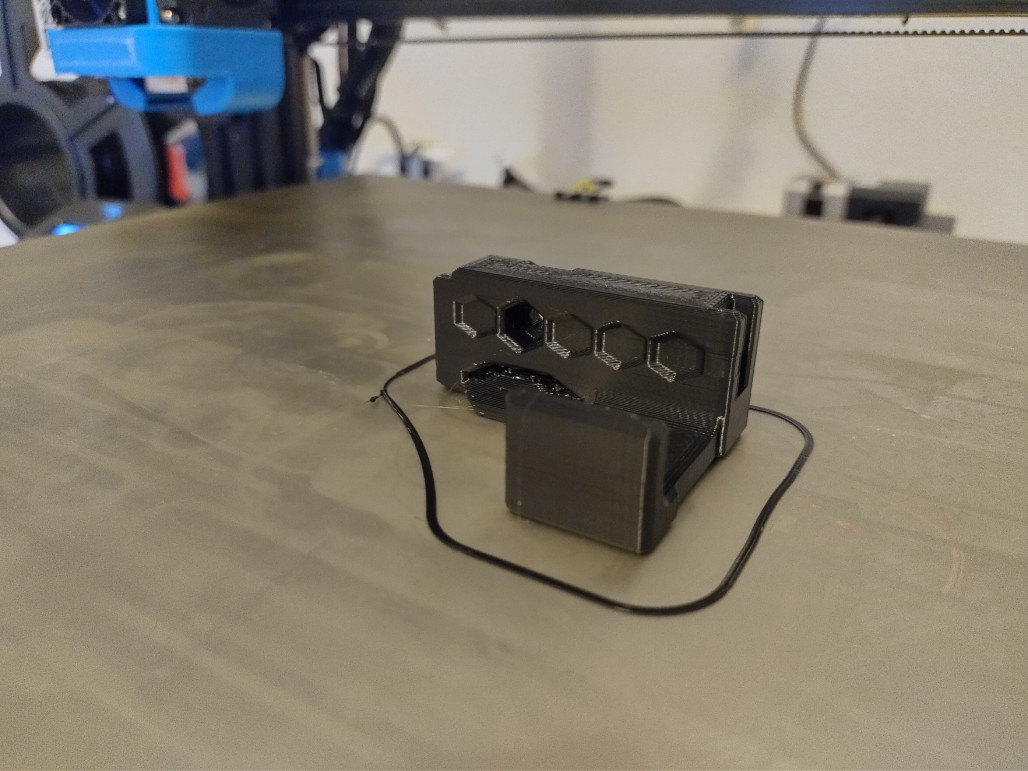

More printing >

After a couple of more iterations...

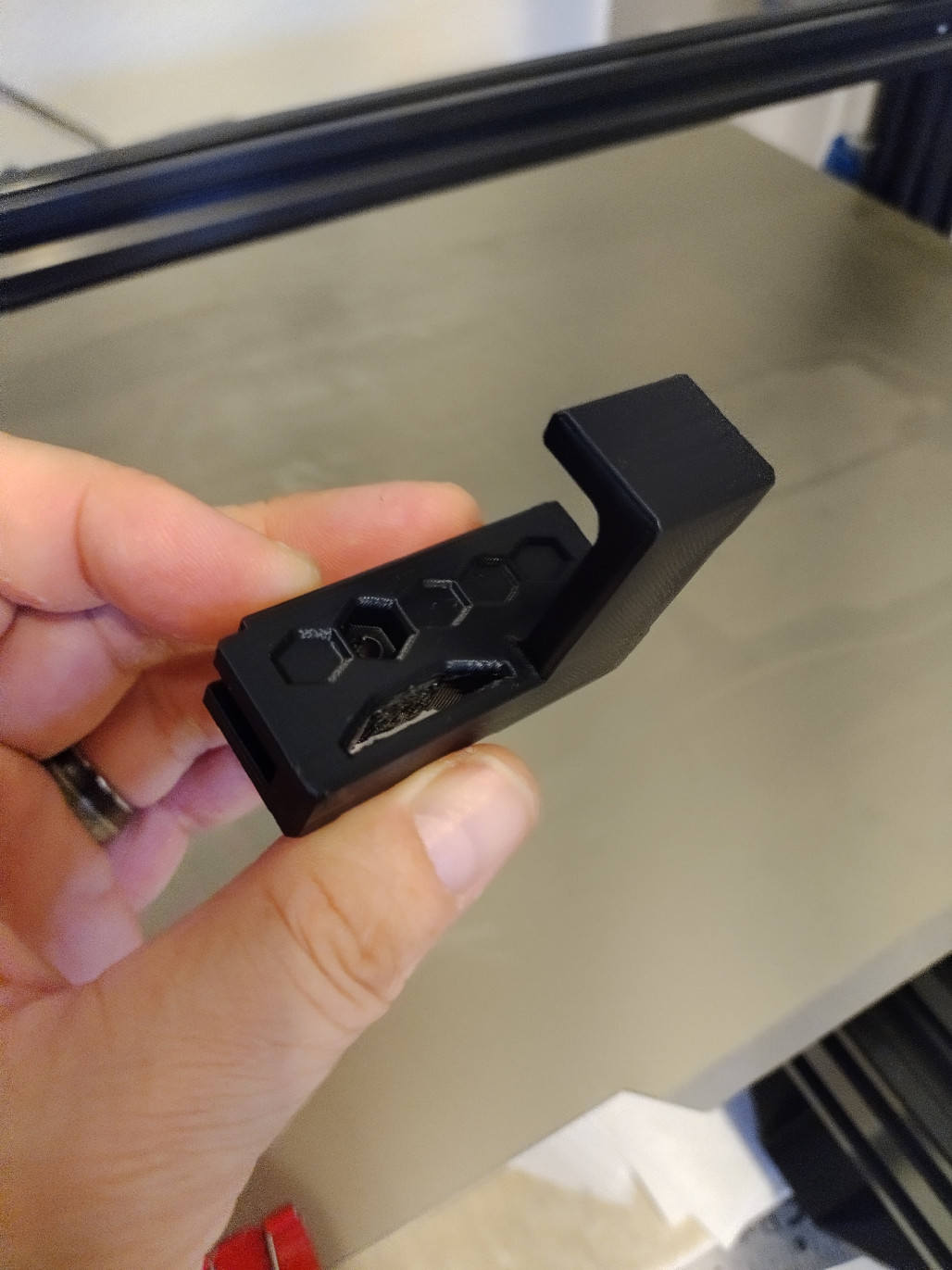

The fitment -the ease of install and more importantly how easily it is to removed is achieved.

Finished version >

I will provide more details and photos with it installed soon.

NOTES-

Here's the thread that sparked this design process >

Razor RC Kraton & Outcast 4S V2 thread

https://www.arrmaforum.com/threads/razor-rc-kraton-outcast-4s-v2-thread.54517/page-15#post-804404

Thanks goes out to:

@Puddlejumpernva - detailed photos of the dovetail interface on the 4S v2.

@Velodromed - confirmation of the Stock 4S v2 CSB dimensions.

It completely replaces the stock OEM Chassis Spine Block (CSB) with my enchanced design to stiffens up the power module to chassis "interface" -by providing a simple and effective integrated brace.

I call it - DiamondBack

Original rough sketches >

Original Test Prints >

Some tweaks were needed to get the fitment right ,plus some refinement to the details of the design...

More printing >

After a couple of more iterations...

The fitment -the ease of install and more importantly how easily it is to removed is achieved.

Finished version >

I will provide more details and photos with it installed soon.

NOTES-

Here's the thread that sparked this design process >

Razor RC Kraton & Outcast 4S V2 thread

https://www.arrmaforum.com/threads/razor-rc-kraton-outcast-4s-v2-thread.54517/page-15#post-804404

Thanks goes out to:

@Puddlejumpernva - detailed photos of the dovetail interface on the 4S v2.

@Velodromed - confirmation of the Stock 4S v2 CSB dimensions.

Last edited: