SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,876

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

Like many recently, I got mine for 4 bills. ( sale)

HH got it to me within 3 days.

Is it truly Ready to Run?

Will it even run at all?

This will end up being my "light" out the box Build Thread. Nothing Fancy going on here.

Initial impression/observations right out the box:

-One motor lead wire was disconnected. No biggy.

-Many screws stripped. Many loose. Mostly the body/Cage screws. Typical of Arrma.

-All 4 shocks low on oil. Can easily hear the air inside them. I've rarely seen this before with all my other 6s rigs. Oil all over. Yet no apparent leaks. Just sloppy assy. Underfilled

-Both F/R Sway bars in their center mounts loose. Not even remotely close to being adjusted. One grub screw barely seated into it's threads.

-Motor Mesh backlash is Non existent. The Pinion is "Slammed Tight" against the Spur gear.

- Used a torch as usual to loosen both Motor mount meshing screws. One hex screw stripped anyway. Not coming off. Will dremel and use a Large flat screwdriver for this. Nothing new with 6s Arrma's here. They use tons of RED Threadlocker. Been there. Will source proper 3mm socket heads as usual.

- All 4 Droop screws are bottomed out with one washer placed under each head. Obviously, they wanted these droop screws bottomed out. Using a washer to predetermine a fixed amount of droop screwed all the way in. Like barely any shock droop at all. Makes no sense to me. I Need 4 upgrade proper droop screws. I believe @Engineer had some DS's bottomed out and stripped out in his FT arms. I'll soon find out if this happened here.

-Front outer BB's need a shim or 2 . Much end play slop. Nothing new. Rears are fine.

- Rear Hubs are missing a .5 mm shim at each of the lower Arm/Hub hingepins. Both sides. Not the first time with Arrma 6s rigs.

-Both Front Upper arm Hinge pin screws were not snugged tight. The upper arms were loose as a result. Causing sloppy Castor angles. Typical. Just tightened them up.

- Wheel alignment all jacked up. Nothing new. Typical. They all need attention out the box. Most any new RTR rig.

- Pivot balls at the Fr. hubs need adjusting. Some were tight , others way loose. Adjust them with the servo link detached before you align the rig. Best way.

- The ESC mains and aux leads were all loose and floppy. Commonly seen. Best to Zip tie as needed. The Cap Pack wires, zip tied to the mains leads are known to break. Secure all. Typical with all Arrma rigs.

- Many complain of the Firma ESC switch cracking apart. I see how impacts may cause this, The switch is mounted to chassis' Side plate and too close to the body.

I might mount the switch to the ESC mount next to the ESC. Hole provisions are there on the ESC mount for the switch. Might prevent switch damage better in this location. IDK.

- Motor's B-phase lead has Heatshrink in 2 hap hazard places, the other leads not. Not sure why??? Just sloppy motor assembly. No attention to detail. Is what it is.

I will update what else I find to keep note of.

______________________________________________________________________________________________________________________________________________________________________________________________

The Following are some positive observations specific to the FT:

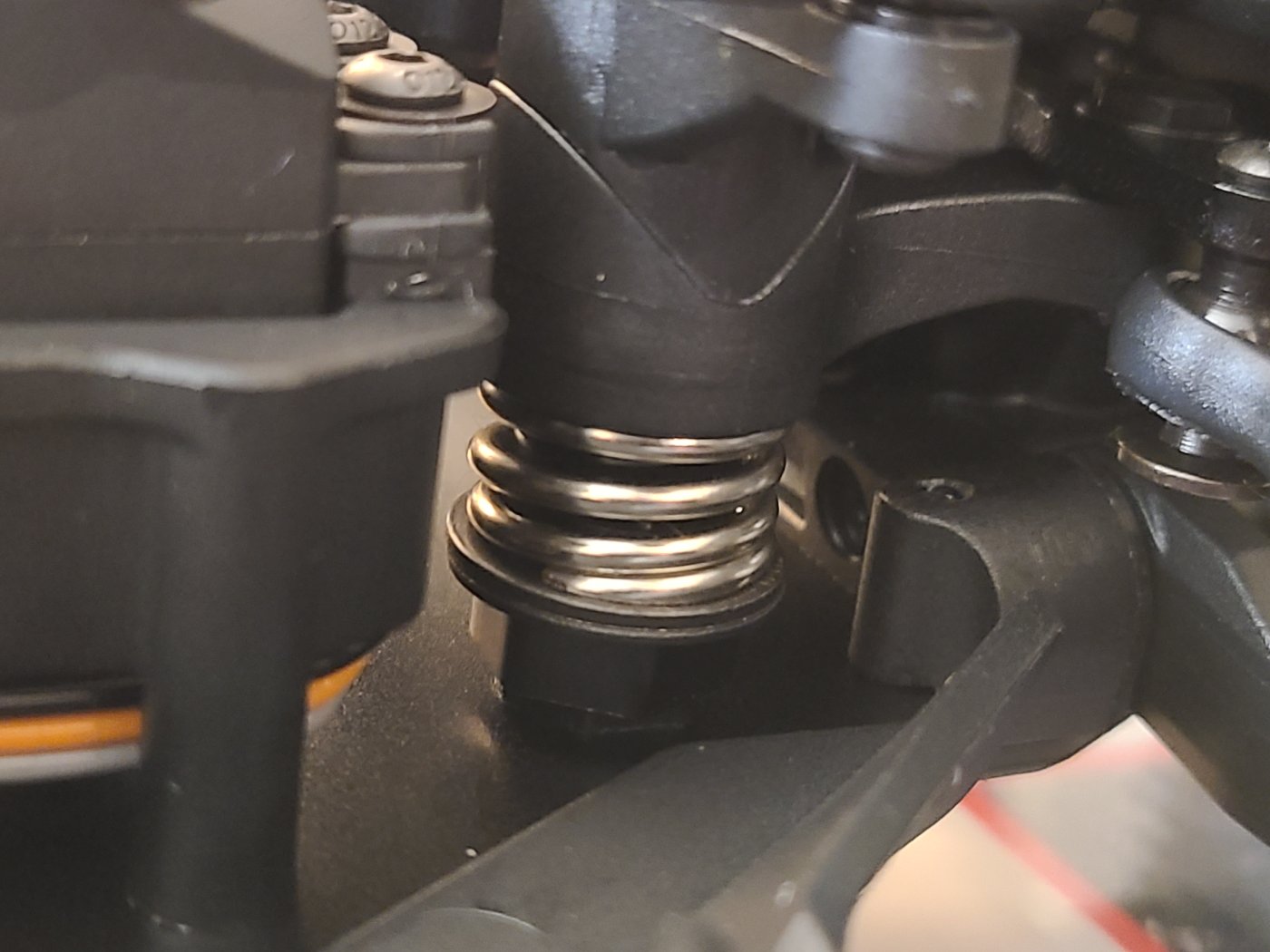

-The Directional FT tires/wheels are well glued and have very beefed up hex hubs. Can't see treads lasting long however. But nice and large. They do have foams in them. I thought they did not as one reviewer has stated. They need to be balanced. Just part of my personal regimen. Many don't.

-FT is the only 6s rig to come with the Metal center diff carrier/case. Nice touch. I use them in most of my 6s rig center diffs.

- The Hand Brake is what it is. Fluff. I know full well, I'll yank it out soon. After I play with it. Just to see how much it sucks. I don't RC with bloated fluffy stuff.

I like a Radio's Trigger and Wheel to drive my rigs. Nothing more.

-Black anodizing throughout does make it look nicer than the common Arrma Red that we are used to seeing. My TLRT Typhon the same. Black makes it look like a serious model.

But that is just aestetics.

- Comes with a Black EXB Steering Top plate. A plus. Mounted with the EXB orientation and a larger Front brace screw. Unlike the TLRT, which was upside down, using a smaller Fr. brace screw. EXB branding was not visible.

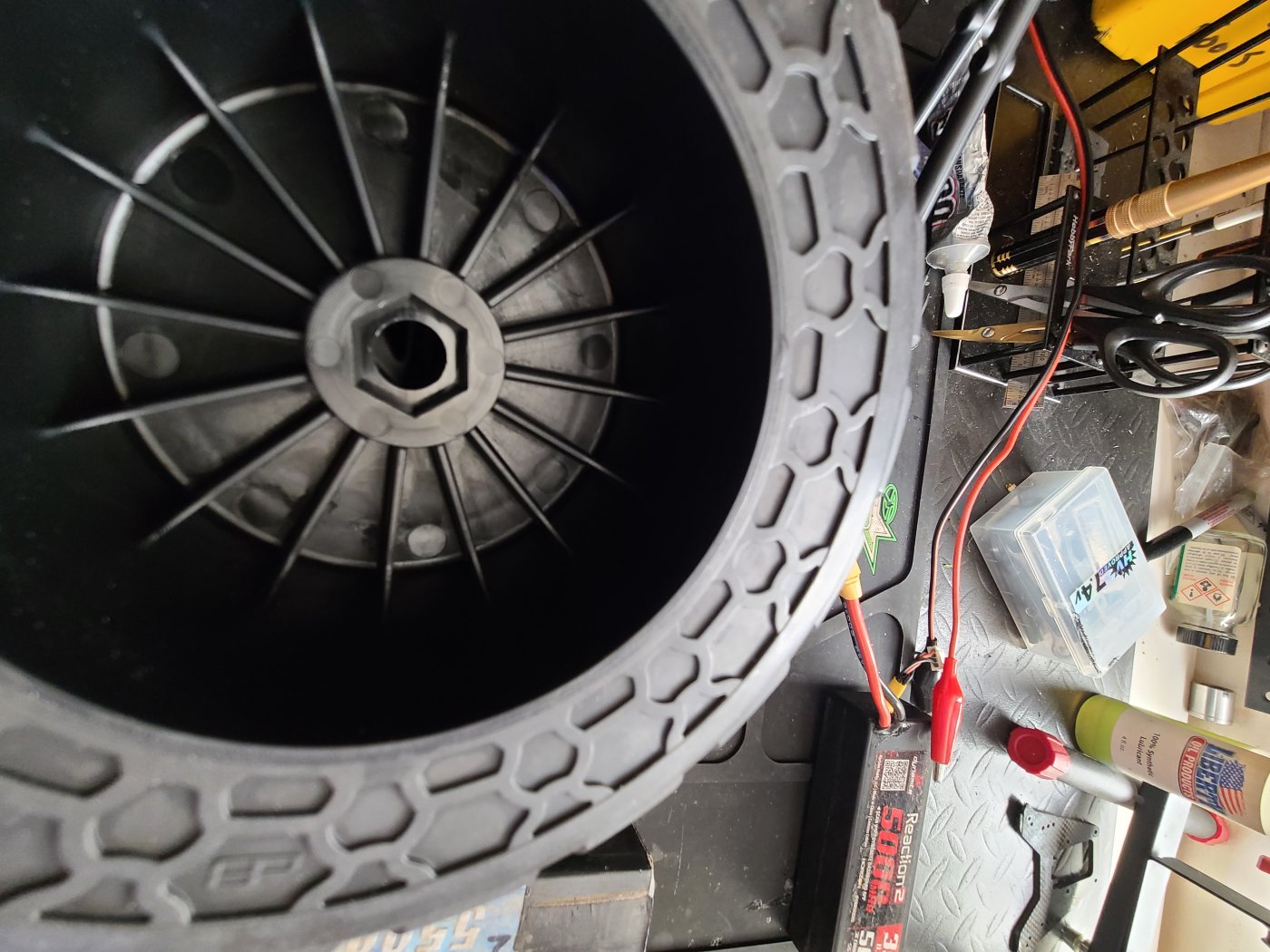

- Another Bonus was the optional "X-Hard" chrome Servo saver spring is included. Not sure yet if shimming will be needed at all.

Some EXB rigs didn't even come with the X-Hard SS spring. I know my TLRT did however.

______________________________________________________________________________________________________________________________________________________________________________________________

I need a few upgrades:

-Fr and R alloy braces. Not sure which ones to get. I think the EXB ones are not a good choice for FT. And the H. brake might cause clearance issues with some beefier Rear braces out there. HB will be tossed anyway.

-DS3235 35 kg AMZ servo. As usual, all my RC rigs. Maybe even the Pro version this time around? (not gambling on the S652 stocker frying the ESC) I don't want to be one of those guys.

- Legit proper Droop screws. Arrmas OE ones will be fine. Avid Ti ones are overkill for this Basher, IMHO.

-CF sleeve over the T2T brace. What I always do. T2T's do bend, unsleeved. And cheaper than buying a BQ CF upgrade one. This is a budget rig for me. Like the price it was....

- (4) 6x10x3mm Sealed BB's for the Steering belcrank. Every 6s Arrma rig needs these. OE Brass bushings suck. The TLRT is the only Arrma that gets them as standard, installed out the box. All other 6s rigs need them as upgrades.

-I'll use the RTR SLT3 Tx for a bit. Checking out the silly Hand brake.... Then I'll use my Spektrum DX5C for this rig. Taking advantage of the pre-installed SR315 DSMR capable Rx in there now. Not my favorite radio however. But will be good enough for bashing the FT.

______________________________________________________________________________________________________________________________________________________________________________________________

-I need to pull all 3 diffs to Check, change oil and shim ( shim F/R).

My go to oil is 60k fr/500k ctr/30k Rr. My Kraton loves this combo. I'll stay with it.

- Need to pull the motor and bench test it's KV rating on my BLX motor analyzer, check timing and BB's.

Then rebuild it, adding my own synthetic BB lube. I won't chance them being dry BB's from the factory. Been there.

This is a simple inexpensive build for me. Hope this helps someone new to the FT or any Arrma 6s rig.

The many well seasoned guys here can surely do better than this. Wallet permitting, we all do RC differently. I I hold this rig to a budget. The best way to enjoy RC IMHO.

As you can see RTR rigs are not truly RTR. Sure you can drive them out the box. But some Pre-Run wrenching makes for a better experience and way less frustration down the road.

No RTR Rigs will be perfect. If you want that level, buy a Kit Brand like Tekno. And build it your self. I always preferred kits years past. But RTR's are the norm now. And best bargain for the price.

I'll post pix here and there as I proceed.

Enjoy.

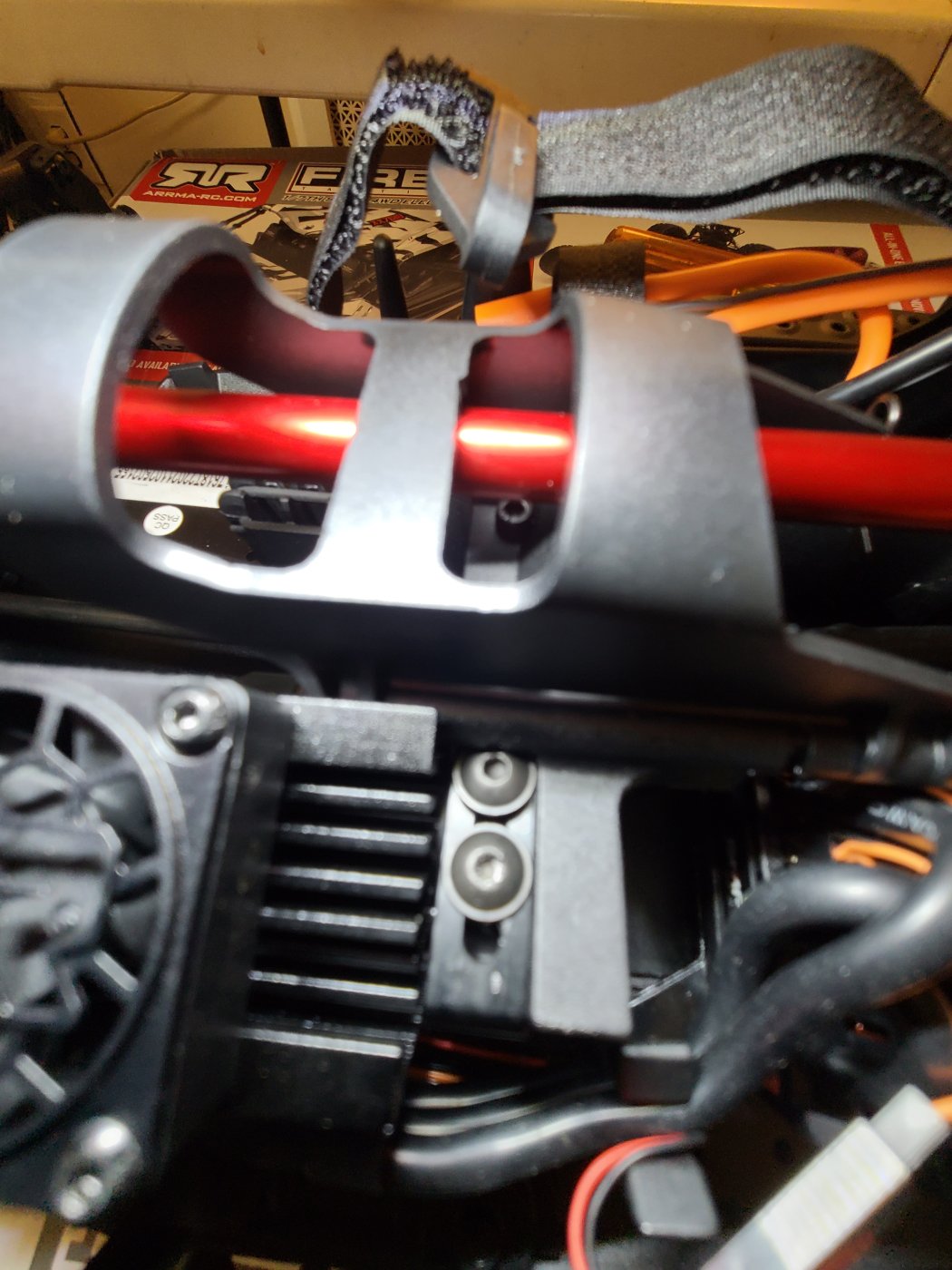

Out the box, one motor lead was disconnected. As Seen above.

X-Hard SS spring does have 2 Shims installed below it already.

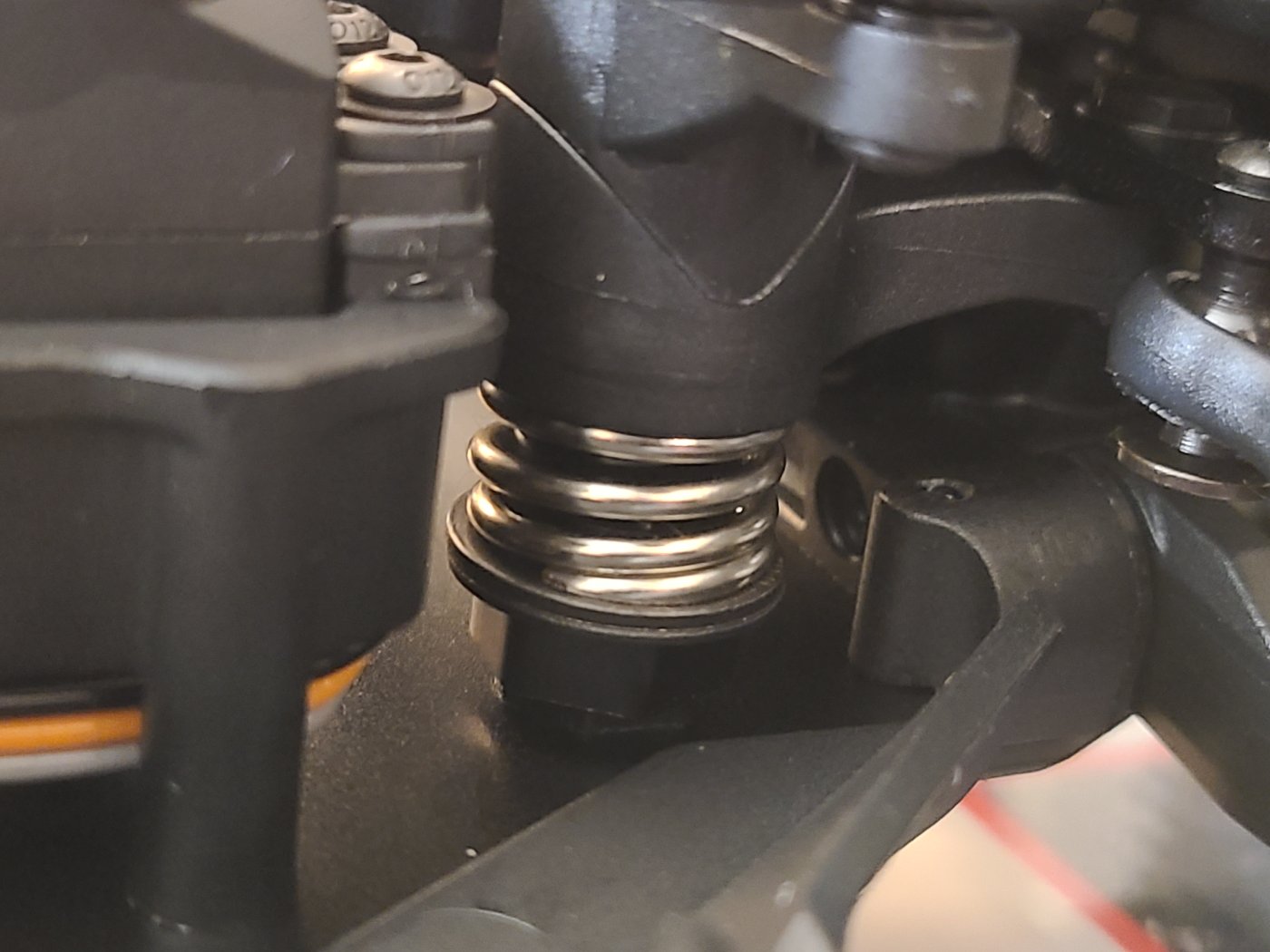

Above shows how I always place my Shock spring perches. Slots angled down. For dirt Egress. Arrma does it opposite. And this only builds up dirt in the perches. I just reverse them. All my 6s Arrma's shocks.

Outer Motor mount screw hex stripped out. Arrma uses too much Red TL used. Despite using my torch it stripped. Is what it is. Been there before. Using "Socket head" 3mm hex screws to replace. Blue TL used only. And any where else on my rigs. Red TL is overkill for these small fasteners, IMHO.

HH got it to me within 3 days.

Is it truly Ready to Run?

Will it even run at all?

This will end up being my "light" out the box Build Thread. Nothing Fancy going on here.

Initial impression/observations right out the box:

-One motor lead wire was disconnected. No biggy.

-Many screws stripped. Many loose. Mostly the body/Cage screws. Typical of Arrma.

-All 4 shocks low on oil. Can easily hear the air inside them. I've rarely seen this before with all my other 6s rigs. Oil all over. Yet no apparent leaks. Just sloppy assy. Underfilled

-Both F/R Sway bars in their center mounts loose. Not even remotely close to being adjusted. One grub screw barely seated into it's threads.

-Motor Mesh backlash is Non existent. The Pinion is "Slammed Tight" against the Spur gear.

- Used a torch as usual to loosen both Motor mount meshing screws. One hex screw stripped anyway. Not coming off. Will dremel and use a Large flat screwdriver for this. Nothing new with 6s Arrma's here. They use tons of RED Threadlocker. Been there. Will source proper 3mm socket heads as usual.

- All 4 Droop screws are bottomed out with one washer placed under each head. Obviously, they wanted these droop screws bottomed out. Using a washer to predetermine a fixed amount of droop screwed all the way in. Like barely any shock droop at all. Makes no sense to me. I Need 4 upgrade proper droop screws. I believe @Engineer had some DS's bottomed out and stripped out in his FT arms. I'll soon find out if this happened here.

-Front outer BB's need a shim or 2 . Much end play slop. Nothing new. Rears are fine.

- Rear Hubs are missing a .5 mm shim at each of the lower Arm/Hub hingepins. Both sides. Not the first time with Arrma 6s rigs.

-Both Front Upper arm Hinge pin screws were not snugged tight. The upper arms were loose as a result. Causing sloppy Castor angles. Typical. Just tightened them up.

- Wheel alignment all jacked up. Nothing new. Typical. They all need attention out the box. Most any new RTR rig.

- Pivot balls at the Fr. hubs need adjusting. Some were tight , others way loose. Adjust them with the servo link detached before you align the rig. Best way.

- The ESC mains and aux leads were all loose and floppy. Commonly seen. Best to Zip tie as needed. The Cap Pack wires, zip tied to the mains leads are known to break. Secure all. Typical with all Arrma rigs.

- Many complain of the Firma ESC switch cracking apart. I see how impacts may cause this, The switch is mounted to chassis' Side plate and too close to the body.

I might mount the switch to the ESC mount next to the ESC. Hole provisions are there on the ESC mount for the switch. Might prevent switch damage better in this location. IDK.

- Motor's B-phase lead has Heatshrink in 2 hap hazard places, the other leads not. Not sure why??? Just sloppy motor assembly. No attention to detail. Is what it is.

I will update what else I find to keep note of.

______________________________________________________________________________________________________________________________________________________________________________________________

The Following are some positive observations specific to the FT:

-The Directional FT tires/wheels are well glued and have very beefed up hex hubs. Can't see treads lasting long however. But nice and large. They do have foams in them. I thought they did not as one reviewer has stated. They need to be balanced. Just part of my personal regimen. Many don't.

-FT is the only 6s rig to come with the Metal center diff carrier/case. Nice touch. I use them in most of my 6s rig center diffs.

- The Hand Brake is what it is. Fluff. I know full well, I'll yank it out soon. After I play with it. Just to see how much it sucks. I don't RC with bloated fluffy stuff.

I like a Radio's Trigger and Wheel to drive my rigs. Nothing more.

-Black anodizing throughout does make it look nicer than the common Arrma Red that we are used to seeing. My TLRT Typhon the same. Black makes it look like a serious model.

But that is just aestetics.

- Comes with a Black EXB Steering Top plate. A plus. Mounted with the EXB orientation and a larger Front brace screw. Unlike the TLRT, which was upside down, using a smaller Fr. brace screw. EXB branding was not visible.

- Another Bonus was the optional "X-Hard" chrome Servo saver spring is included. Not sure yet if shimming will be needed at all.

Some EXB rigs didn't even come with the X-Hard SS spring. I know my TLRT did however.

______________________________________________________________________________________________________________________________________________________________________________________________

I need a few upgrades:

-Fr and R alloy braces. Not sure which ones to get. I think the EXB ones are not a good choice for FT. And the H. brake might cause clearance issues with some beefier Rear braces out there. HB will be tossed anyway.

-DS3235 35 kg AMZ servo. As usual, all my RC rigs. Maybe even the Pro version this time around? (not gambling on the S652 stocker frying the ESC) I don't want to be one of those guys.

- Legit proper Droop screws. Arrmas OE ones will be fine. Avid Ti ones are overkill for this Basher, IMHO.

-CF sleeve over the T2T brace. What I always do. T2T's do bend, unsleeved. And cheaper than buying a BQ CF upgrade one. This is a budget rig for me. Like the price it was....

- (4) 6x10x3mm Sealed BB's for the Steering belcrank. Every 6s Arrma rig needs these. OE Brass bushings suck. The TLRT is the only Arrma that gets them as standard, installed out the box. All other 6s rigs need them as upgrades.

-I'll use the RTR SLT3 Tx for a bit. Checking out the silly Hand brake.... Then I'll use my Spektrum DX5C for this rig. Taking advantage of the pre-installed SR315 DSMR capable Rx in there now. Not my favorite radio however. But will be good enough for bashing the FT.

______________________________________________________________________________________________________________________________________________________________________________________________

-I need to pull all 3 diffs to Check, change oil and shim ( shim F/R).

My go to oil is 60k fr/500k ctr/30k Rr. My Kraton loves this combo. I'll stay with it.

- Need to pull the motor and bench test it's KV rating on my BLX motor analyzer, check timing and BB's.

Then rebuild it, adding my own synthetic BB lube. I won't chance them being dry BB's from the factory. Been there.

This is a simple inexpensive build for me. Hope this helps someone new to the FT or any Arrma 6s rig.

The many well seasoned guys here can surely do better than this. Wallet permitting, we all do RC differently. I I hold this rig to a budget. The best way to enjoy RC IMHO.

As you can see RTR rigs are not truly RTR. Sure you can drive them out the box. But some Pre-Run wrenching makes for a better experience and way less frustration down the road.

No RTR Rigs will be perfect. If you want that level, buy a Kit Brand like Tekno. And build it your self. I always preferred kits years past. But RTR's are the norm now. And best bargain for the price.

I'll post pix here and there as I proceed.

Enjoy.

Out the box, one motor lead was disconnected. As Seen above.

X-Hard SS spring does have 2 Shims installed below it already.

Above shows how I always place my Shock spring perches. Slots angled down. For dirt Egress. Arrma does it opposite. And this only builds up dirt in the perches. I just reverse them. All my 6s Arrma's shocks.

Outer Motor mount screw hex stripped out. Arrma uses too much Red TL used. Despite using my torch it stripped. Is what it is. Been there before. Using "Socket head" 3mm hex screws to replace. Blue TL used only. And any where else on my rigs. Red TL is overkill for these small fasteners, IMHO.

Last edited: