Notoriousone

Very Active Member

- Messages

- 620

- Reaction score

- 1,461

- Arrma RC's

- Limitless

- Mojave

- Notorious

- Typhon 6s

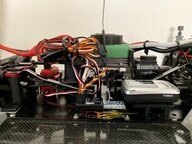

So, I got bit by the speedrun bug a few months ago and thought Id try building my basic blue V3 Typhon 6S into something a little faster. I've been in RC for years and had many vehicles, but never had a dedicated speedrunner. First thing I did for a month was research, and I quickly saw that there wasn't much info to be found in general on building one of these things. So after some looking around I came across this forum, a few others, facebook groups and the like with some solid info. After reading a bunch of good info and ordering up parts, the transformation began.. I can get into more detail later, but this is the result so far..

Stock V3 Typhon 6S chassis, suspension, arms and linkage, Saga custom RC carbon battery trays

Rear hubs and arms shimmed to reduce play, rear wheels 0 degree plate installed. Shocks have RPM limiter clips installed

Center diff replaced with EM performance 8mm spool with 29t pinion/34t spur installed. 500k diff fluid in front and rear diffs

Hot racing front and rear chassis braces, motor mount, and center diff mount, full bearing kit

Alza racing center diff top plate/Mamba XLX mount, ultra low shock towers front and rear

Mugen Seiki MRX front bumper/foam, 3D printed rear body mounts

Poseidon 1800 KV motor, Castle fan, Castle Mamba XLX Esc, Killmode 13,200 UF cap pack

Dual SMC 7600 Mah 3S matched battery packs, Castle 6.5 battery and 8mm motor connectors

BSR racing foam tires, double pink compound

Ipanema Blackhawk warrior body

Futaba 4PV with R314 telemetry receiver

During setup I had a few issues with things like motor rotation direction, throttle channels reversed and other minor things that were resolved eventually. So far I've only done 4 test runs in the street outside my house with no body, as the body isn't ready yet. I live in the middle of the city so its hard to find big open areas with no traffic, I had to get out there at 6 am on a sunday to test lol. All test runs were over 80 mph, with a best of 93 mph before I called it quits. This thing is a beast for sure, at no point was I past half throttle. It ran great with no issues whatsoever, the motor was barely warm to the the touch, and even with no body and a few bumps in the street it ran straight and true so I'm pretty happy so far. Once the body is reinforced and ready, and I can run in a proper setting I'm hoping to see somewhere around 125 to 130 mph, at least.

Stock V3 Typhon 6S chassis, suspension, arms and linkage, Saga custom RC carbon battery trays

Rear hubs and arms shimmed to reduce play, rear wheels 0 degree plate installed. Shocks have RPM limiter clips installed

Center diff replaced with EM performance 8mm spool with 29t pinion/34t spur installed. 500k diff fluid in front and rear diffs

Hot racing front and rear chassis braces, motor mount, and center diff mount, full bearing kit

Alza racing center diff top plate/Mamba XLX mount, ultra low shock towers front and rear

Mugen Seiki MRX front bumper/foam, 3D printed rear body mounts

Poseidon 1800 KV motor, Castle fan, Castle Mamba XLX Esc, Killmode 13,200 UF cap pack

Dual SMC 7600 Mah 3S matched battery packs, Castle 6.5 battery and 8mm motor connectors

BSR racing foam tires, double pink compound

Ipanema Blackhawk warrior body

Futaba 4PV with R314 telemetry receiver

During setup I had a few issues with things like motor rotation direction, throttle channels reversed and other minor things that were resolved eventually. So far I've only done 4 test runs in the street outside my house with no body, as the body isn't ready yet. I live in the middle of the city so its hard to find big open areas with no traffic, I had to get out there at 6 am on a sunday to test lol. All test runs were over 80 mph, with a best of 93 mph before I called it quits. This thing is a beast for sure, at no point was I past half throttle. It ran great with no issues whatsoever, the motor was barely warm to the the touch, and even with no body and a few bumps in the street it ran straight and true so I'm pretty happy so far. Once the body is reinforced and ready, and I can run in a proper setting I'm hoping to see somewhere around 125 to 130 mph, at least.

Attachments

Last edited: