Aww man you wont make me a part if I offered to pay for your services?It must remain a hobby, so it's not like i intend to run a manufacturing workshop.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Forged carbon parts

- Thread starter rotauq

- Start date

-

- Tags

- carbon fiber

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

- Thread starter

- #42

I am the kind of guy who would rather occasionly make some for free/cost price or help/teach someone. Doing someone a favor is still hobby, selling is not. don't want any side jobs, i have a good dayjob and don't want anything that would certainly interfere with it.

Definitely. Was just messin with you. You don't come off as someone who wouldn't help out a fellow Hobbyist.I am the kind of guy who would rather occasionly make some for free/cost price or help/teach someone. Doing someone a favor is still hobby, selling is not. don't want any side jobs, i have a good dayjob and don't want anything that would certainly interfere with it.

- Thread starter

- #44

So today the kit arrived:

I really like that it's stocked up for 5x

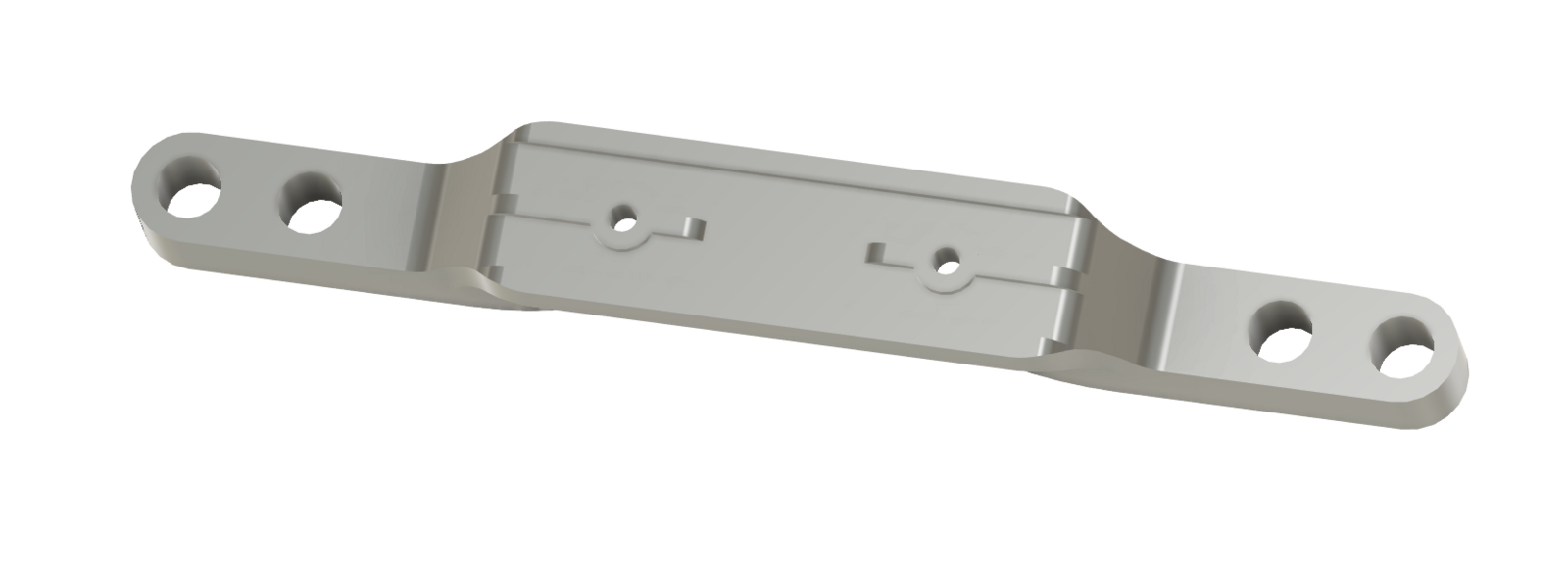

For my first attempt i've been thinking about just making a strong non-bending bodystand:

Whiles is the meantime designing a nice and strong 'diffuser cage'

use case:

- Diffuser topside always looks silly with a GT body. It always sticks out.

- The rear, especially with a onbody spoiler, is always weak

- I want an optional 'carry the car with one hand' handle bar at the back with minimal drag.

I've not finalized the design yet, but after a few iterations is looks like this. (no handle yet)

I would prefer to make it a one-piece part, but that makes the mold quite big and complicated, so it will likely end in 3 or 4 parts. The side panel on the picture is from a earlier iteration.

I really like that it's stocked up for 5x

For my first attempt i've been thinking about just making a strong non-bending bodystand:

Whiles is the meantime designing a nice and strong 'diffuser cage'

use case:

- Diffuser topside always looks silly with a GT body. It always sticks out.

- The rear, especially with a onbody spoiler, is always weak

- I want an optional 'carry the car with one hand' handle bar at the back with minimal drag.

I've not finalized the design yet, but after a few iterations is looks like this. (no handle yet)

I would prefer to make it a one-piece part, but that makes the mold quite big and complicated, so it will likely end in 3 or 4 parts. The side panel on the picture is from a earlier iteration.

- Thread starter

- #45

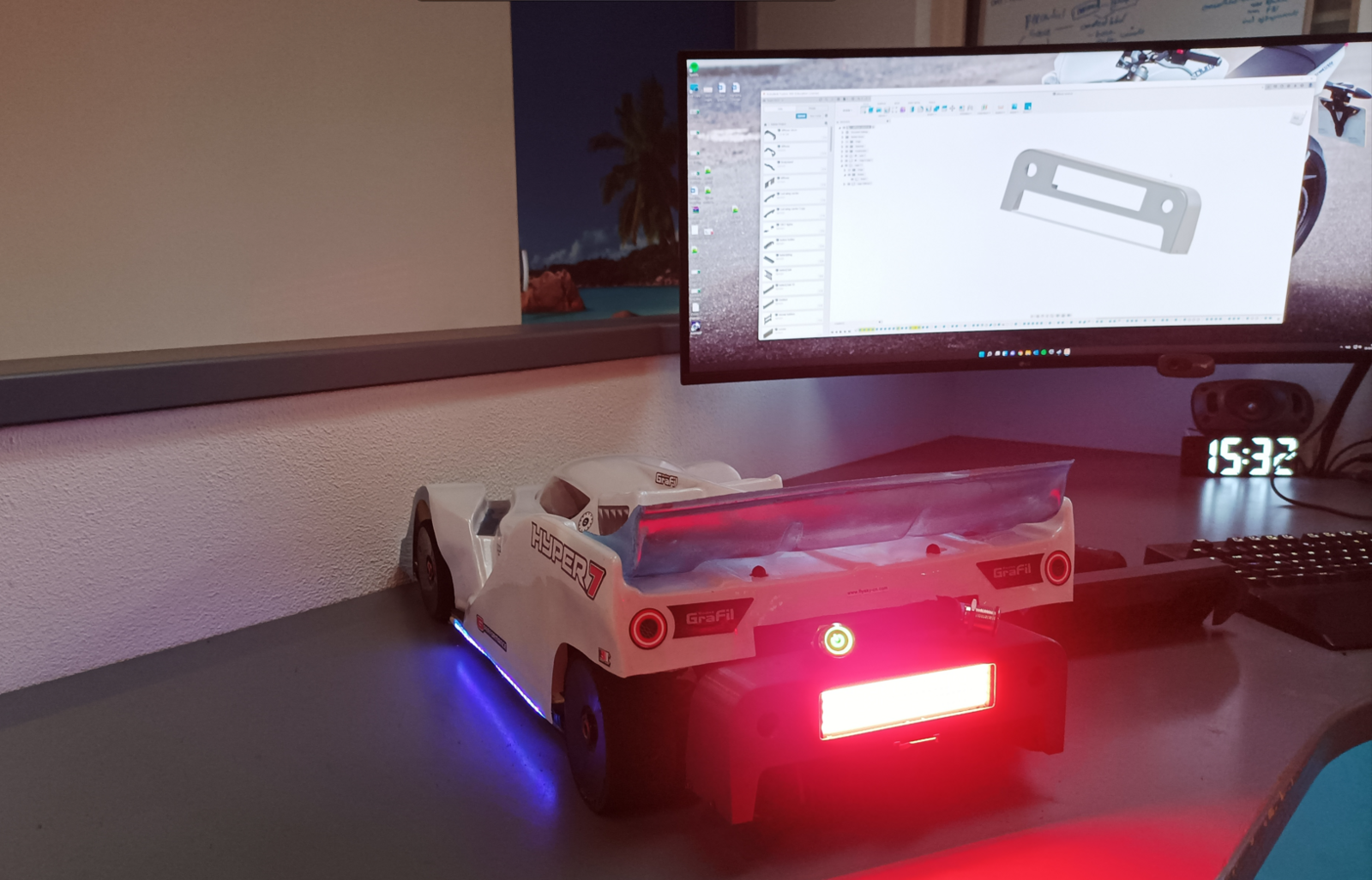

I switched over to my version for my short Hyper7 setup as it's more likely to be forged in one piece.

This prototype is maybe a bit too curvy, but the integration of my power buttens and my flashing COB panel looks nice:

The diffuser is cut back about 20%. The replaceble part in the center is still full lenght (as a reference point)

I'll edge the case so it will match the diffuser airflow.

The power buttons need to be detached to be fitted in, (which i wont do for this prototype), but the COB led makes visibility good

So a few tweaks to go and then it's time to make the molds.

This prototype is maybe a bit too curvy, but the integration of my power buttens and my flashing COB panel looks nice:

The diffuser is cut back about 20%. The replaceble part in the center is still full lenght (as a reference point)

I'll edge the case so it will match the diffuser airflow.

The power buttons need to be detached to be fitted in, (which i wont do for this prototype), but the COB led makes visibility good

So a few tweaks to go and then it's time to make the molds.

- Thread starter

- #46

Update:

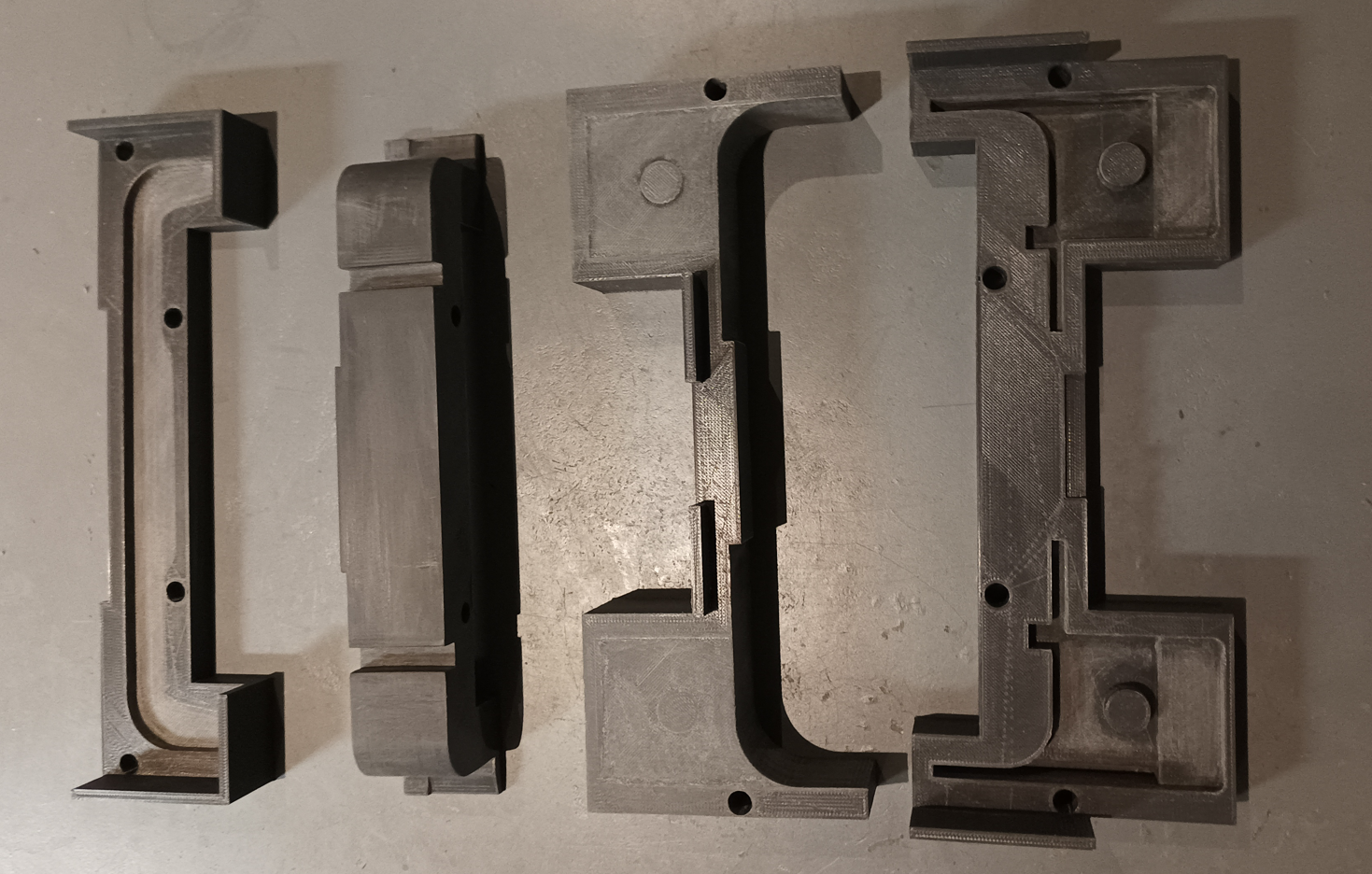

I made some tweaks to the parts, finished the 4 piece mold design and spend 50h on printing and sanding:

Because it's a tricky design it was quite hard to get all the fiber in there in time. Luckily i had my cousin over so a welcome extra pair of hands. Alone I would not have been able to get it done. Future parts are gonna be less complex.

It's all clammed up and curing atm

I hope the result is gonna be worth the effort.

I made some tweaks to the parts, finished the 4 piece mold design and spend 50h on printing and sanding:

Because it's a tricky design it was quite hard to get all the fiber in there in time. Luckily i had my cousin over so a welcome extra pair of hands. Alone I would not have been able to get it done. Future parts are gonna be less complex.

It's all clammed up and curing atm

I hope the result is gonna be worth the effort.

- Messages

- 10,087

- Reaction score

- 24,794

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

Update:

I made some tweaks to the parts, finished the 4 piece mold design and spend 50h on printing and sanding:

View attachment 189285

Because it's a tricky design it was quite hard to get all the fiber in there in time. Luckily i had my cousin over so a welcome extra pair of hands. Alone I would not have been able to get it done. Future parts are gonna be less complex.

It's all clammed up and curing atm

View attachment 189288

I hope the result is gonna be worth the effort.

Awesome man! Cant wait to see how it goes!!!

- Thread starter

- #48

The only way i can describe it is, awesome

These pics are after some rough cleaning. It's rock solid and just a few spots (out of sight) where it's not completely filled up.

These pics are after some rough cleaning. It's rock solid and just a few spots (out of sight) where it's not completely filled up.

- Thread starter

- #49

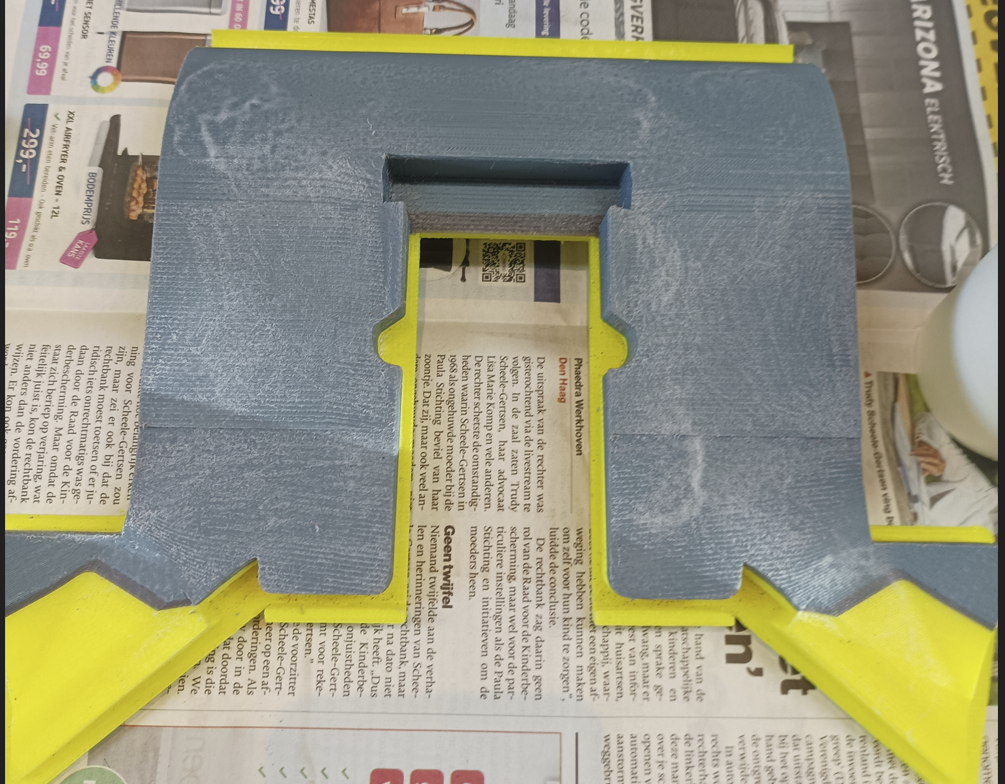

So the next step was to create a diffuser for the VTE2. I does not have one and the chassis end-points are not as complex as the arrma's.

I designated my V11 to be the minimum viable product. I first designed a more wishfull complex design, sparring with @LibertyMKiii.

But optimizing it for the fabrication process i simplefied it a lot again, with this as first full prototype to be forged.

The mould has a 3 piece base, good for a 40h print (+extra 18h as the rear part failed the first time) The rear still has some layershift at 40mm, but i decided to sand it down rather than to do an other print.

The press took 40h to print, but it took much longer as i had to stock up on more pla whiles it ran out halfway.

I don't expect a perfect result. I purposely did a minimum effort approach. The first time it was rather stressfull, so i figured, what if just don't stress at all.

Now it's waiting time...

I designated my V11 to be the minimum viable product. I first designed a more wishfull complex design, sparring with @LibertyMKiii.

But optimizing it for the fabrication process i simplefied it a lot again, with this as first full prototype to be forged.

The mould has a 3 piece base, good for a 40h print (+extra 18h as the rear part failed the first time) The rear still has some layershift at 40mm, but i decided to sand it down rather than to do an other print.

The press took 40h to print, but it took much longer as i had to stock up on more pla whiles it ran out halfway.

I don't expect a perfect result. I purposely did a minimum effort approach. The first time it was rather stressfull, so i figured, what if just don't stress at all.

Now it's waiting time...

- Messages

- 10,087

- Reaction score

- 24,794

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

I'm on the edge of my seat here. Can't wait to see how it turns out!!!

- Thread starter

- #51

I made a little design mistake as the piece locked in the 3 piece bottom, so there was only one option.

732 cuts and 3 burnmarks in my hand later, i got it out.

It's still rough, i'll clean it up now. As expected it's not perfect, but i am pretty sure i can make it functional. The general shape is there

732 cuts and 3 burnmarks in my hand later, i got it out.

It's still rough, i'll clean it up now. As expected it's not perfect, but i am pretty sure i can make it functional. The general shape is there

- Messages

- 10,087

- Reaction score

- 24,794

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

- Thread starter

- #53

Mr ground effect RC also discovered the forged carbon

Making spoilers is always a good idea and less complex than a diffuser

After some prepping it's starting to look much better. I am considering to sand it down much further as it's currently 360gr, slightly heavier than i would like it to be.

Making spoilers is always a good idea and less complex than a diffuser

After some prepping it's starting to look much better. I am considering to sand it down much further as it's currently 360gr, slightly heavier than i would like it to be.

- Messages

- 10,087

- Reaction score

- 24,794

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

Mr ground effect RC also discovered the forged carbon

Making spoilers is always a good idea and less complex than a diffuser

After some prepping it's starting to look much better. I am considering to sand it down much further as it's currently 360gr, slightly heavier than i would like it to be.

View attachment 197051

View attachment 197052

Definitely borrowing that gold flake idea. That looks great!

FYI I have used superglue or just more epoxy resin to fill voids.

If you plan to use a good 2k clear on it 3xx grit sanding marks will not show.

- Messages

- 4,379

- Reaction score

- 7,388

- Arrma RC's

- Limitless

- Nero

- Talion

It has been awhile since this thread was active. I watched that forged carbon video this morning (before I found this thread). I want to make some for my limitless. If I enjoy doing it, I might make it a side job. Do you have any advise on getting this to work right? I don't have a 3d printer, but I want to buy one in the next 12 months. I would like recommendations for a mid range 3d printer.

Tex Koder

2D , 3D Not a problem. I'll take that Challenge.

Lifetime Premium!

Premium Member

ArrmaForum Fan

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 10,008

- Reaction score

- 25,220

- Location

- Dallas, TX (USA)

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Mojave

- Nero

- Senton 3s

- Typhon 6s

- Vendetta

It has been awhile since this thread was active. I watched that forged carbon video this morning (before I found this thread). I want to make some for my limitless. If I enjoy doing it, I might make it a side job. Do you have any advise on getting this to work right? I don't have a 3d printer, but I want to buy one in the next 12 months. I would like recommendations for a mid range 3d printer.

Here's some general thinking points:

1. How "big" a part you want to print (at one go) or if you're willing to break the parts into pieces and print separately -You can get away with using smaller printer(s?)..

Think about how much space/room you have to dedicate to the printer itself first ,to have an idea..

For reference-

I'm using a desk - 30" D x 60" W for my printer* and control laptop.

You need to realize that the printer will need more space around it than just it's print volume specs. Because it doesn't move forward and back. And for safety.. you don't want it to vibrate off the desk during print sessions which could last several hours/days.

2. Current Printer Brands (not in any particular order ,well maybe in some kind of order..):

Prusa

Ultimaker

Creality

Trevo

Anycubic

Makerbot

3. There's also the 3D Design Software you need to decide on using to create your parts..

4. Then there's the "slicer" software/app you want to use to prep your 3D Design file to get it to machine code (gCode) for printing.

5. Lastly, learn about filament types and their strength & weaknesses and the proper settings/configurations you need to learn to set to use them effectively with your printer. (Each filament type requires custom tweaks/settings.)

Feel free to browse my Build Thread - Table of Contents..

I've listed (with Notes & links) to everything that I'm using for my 3D production.

*400mm x 400mm

Last edited:

- Messages

- 10,087

- Reaction score

- 24,794

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

We have had many threads on this, but overall the most recommended is the Creality Ender 3 V2 for the low cost and easy ability to be upgraded. If you do not want to invest in upgrading and need a large print size then the CR-10 is a solid option (300x300x400). (there are Ender 3 XL print upgrade kits)It has been awhile since this thread was active. I watched that forged carbon video this morning (before I found this thread). I want to make some for my limitless. If I enjoy doing it, I might make it a side job. Do you have any advise on getting this to work right? I don't have a 3d printer, but I want to buy one in the next 12 months. I would like recommendations for a mid range 3d printer.

Another tip is that you should not get epoxy on your skin. I did it too many times working with CF and now I get severely sick with minor exposures to it.

- Thread starter

- #58

Tex covered most of the 3D printer part of the question, a little extra adviseIt has been awhile since this thread was active. I watched that forged carbon video this morning (before I found this thread). I want to make some for my limitless. If I enjoy doing it, I might make it a side job. Do you have any advise on getting this to work right? I don't have a 3d printer, but I want to buy one in the next 12 months. I would like recommendations for a mid range 3d printer.

I have 2 printers and that's a blessing on its own. Especially when you make multiple part designs and prototype a lot it's great not to constantly having to wait for that one prototype to finish, while you have 2-3 more concepts in the queue.

One is a Tevo Nereus (320x320) which is my goto printer for bigger parts. It was a serious challenge to get all slicing settings right for this one. Before i upgraded the driverboards it was extremely noisy as well. You wouldn't want to sit in the same room. After all tweaks it's a great printer.

The other is a smaller creality ender 3 v2 is great out of the box. Everything just worked perfect from the start and everyone i advised to start with this one, confirmed it. Regardless of you bigger plans, I'd say start with a printer like this. It's cheap and will kickstart your 3d experience. Go bigger with the second one.

As for carbon forging. Start small. Don't make your designs to complex. Same as with 3d printing, it's smart to make multiple part designs.

- Messages

- 10,087

- Reaction score

- 24,794

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

I think @Tex Koder needs to make and sell some forged carbon parts

Then he can do all the manufacturing in-house and cut out the middle man. I don't have the time for this stuff, but it seems he might.

Then he can do all the manufacturing in-house and cut out the middle man. I don't have the time for this stuff, but it seems he might.

- Messages

- 4,379

- Reaction score

- 7,388

- Arrma RC's

- Limitless

- Nero

- Talion

But, I was thinking of doing that...I think @Tex Koder needs to make and sell some forged carbon parts

Then he can do all the manufacturing in-house and cut out the middle man. I don't have the time for this stuff, but it seems he might.

Similar threads

- Replies

- 4

- Views

- 554

- Replies

- 2

- Views

- 438