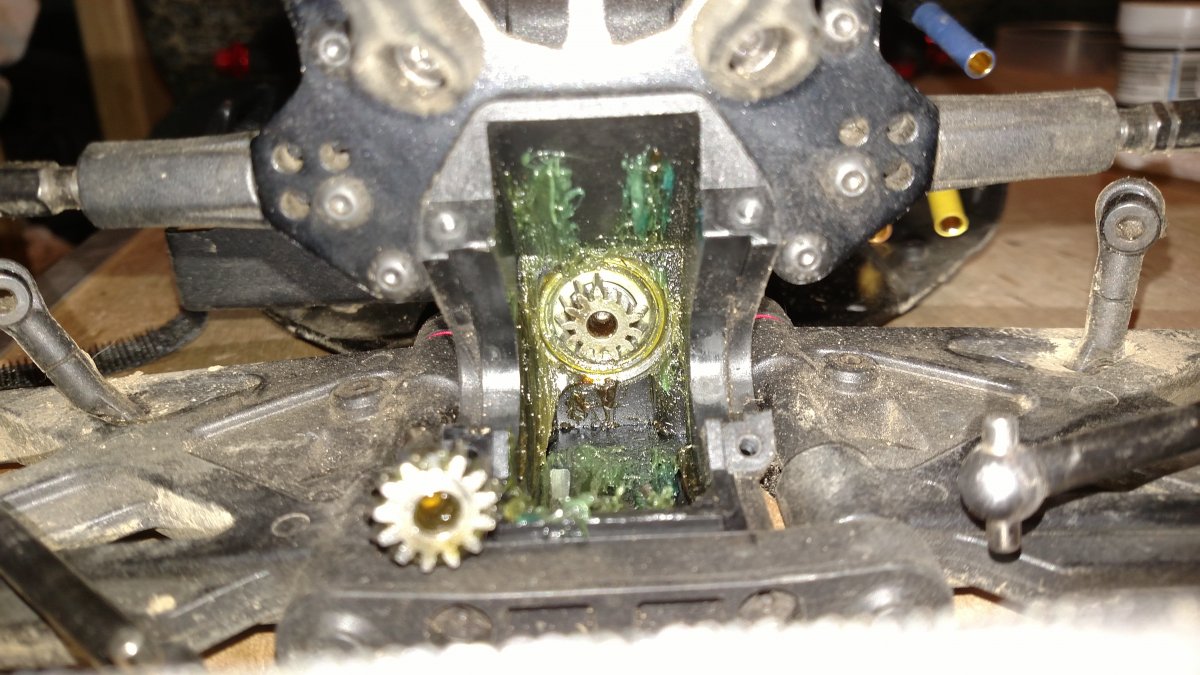

Hey guys, recently truggified my son's Typhon, posted pics and running vid in media. You can hear grinding noise after muffed up jump off side of ramp. This vid was after brutal bash session that had broken center diff planetary gear, left car with rear wheel drive only. Fixed that, then truggified rig. Anyway, discovered after vid, front diff main input gear was missing a tooth and smaller input bearing was blown. Fixed that only to discover rear input gear also grinding, missing 2 teeth, bearings intact. My question is do any of you have an idea as to how both inputs could fail in such short order? What condition could cause this? Center diff is shimmed and seems OK, need to tear open again to verify. Any ideas/theories/suggestions much appreciated. These are expensive gears, don't want a repeat failure like this. Here's a pic of front gear with same rear input still in place. They both have a hillbilly smile missing teeth!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Typhon Help with broken input gears?

- Thread starter Rich Duperbash

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

- Thread starter

- #3

Dirt, grass, bark. If you watch vid, I shave/miss ramp with right wheels on hard throttle, wondering if that contributed to failure by locking gears somewhat.Are you running on asphalt,or dirt?

Cant find the vid sir . But if wheels are spinning in high speed and sudden stops like hooking up on gras or other it may cause diff fail. Like leaving a jump and landing on full throttle. Shim front and rear, both internal and external.

- Thread starter

- #5

Thanks Thomas, I was hoping you'd see my thread. Really respect your expert input and will fully shim my son's rig internal and external. The vid is in media under Typhon Truggified from 2-3 days ago. I was bummed cuz it was so fun to drive and ramp launch with new setup, really a cool minibeast. Waiting for new input gears to arrive. Thanks again.Cant find the vid sir . But if wheels are spinning in high speed and sudden stops like hooking up on gras or other it may cause diff fail. Like leaving a jump and landing on full throttle. Shim front and rear, both internal and external.

- Thread starter

- #6

Thomas I had a big air bash with my son today, he was launching big flips with Truggified Typhon, ended up busting both center diff planetary gears despite being shimmed. Rebuilt, but this time added one extra planetary shim, 1 on one side 2 behind pin on other side. Total of 6 satellite shims. Doesn't feel too tight with freespin off truck, going to try it. Just wondering if you've ever done this. Running 100k like before. He did have a couple nose and tail landings, but bashed quite well! I hit a 15 foot backflip too, all very big dirCant find the vid sir . But if wheels are spinning in high speed and sudden stops like hooking up on gras or other it may cause diff fail. Like leaving a jump and landing on full throttle. Shim front and rear, both internal and external.

Last edited:

Thomas I had a big air bash with my son today, he was launching big flips with Truggified Typhon, ended up busting both center diff planetary gears despite being shimmed. Rebuilt, but this time added one extra planetary shim, 1 on one side 2 behind pin on other side. Total of 6 satellite shims. Doesn't feel too tight with freespin off truck, going to try it. Just wondering if you've ever done this. Running 100k like before. He did have a couple nose and tail landings, but bashed quite well! I hit a 15 foot backflip too, all very big dirView attachment 4810 dirt jump park stuff.

Sounds AWSM Mate, may i ask, was there still heavy fast rotating wheels or throttle during that landing?, shiming is all about feeling, if the diff feels "good" with 1,2 or 3 just use it

- Thread starter

- #8

Nope. Just fat airs with mostly good wheel landings, no hard throttle landings, all dirt. I'll try this out and see how she goes. I've tried to establish a good feel for shimming, just seems there should be some movement or play for gears to mesh right. Wondering if cast metal is relatively brittle. Always splits in half where pin sits. Wondering if I may have stressed gears by pushing on drive cup instead of spur when trying to seat diff bearing into motor mount. Really tight fit on mine, Avid yellow sealed bearing was a female dog to fully seat. Thanks for your help. Like wrenching just don't want to keep breaking gears so often.Sounds AWSM Mate, may i ask, was there still heavy fast rotating wheels or throttle during that landing?, shiming is all about feeling, if the diff feels "good" with 1,2 or 3 just use it

bennyly

Active Member

Nope. Just fat airs with mostly good wheel landings, no hard throttle landings, all dirt. I'll try this out and see how she goes. I've tried to establish a good feel for shimming, just seems there should be some movement or play for gears to mesh right. Wondering if cast metal is relatively brittle. Always splits in half where pin sits. Wondering if I may have stressed gears by pushing on drive cup instead of spur when trying to seat diff bearing into motor mount. Really tight fit on mine, Avid yellow sealed bearing was a female dog to fully seat. Thanks for your help. Like wrenching just don't want to keep breaking gears so often.

Hey Rich, i know this is a old post but was wondering what shims you guys use to shim the input gears, front and rear? Ive been through two rear input's so far on my kraton and don't really understand why.. and are you shimming behind the diff cup as well? thanks

- Thread starter

- #10

I generally use 2-3 Kyosho or Tekno bearing shims TKR1222 on the crown gear side bearing to tighten the mesh between the crown and inputs. 3 is sometimes impossible to fit between the diff case and bearing. Usually 2 works just fine. Make sure your diff cover secures down 100% or the diff will move on hard throttle and jack your input. I generally load my gears up with quality synthetic marine grease like Nano Pro MT Marine.Hey Rich, i know this is a old post but was wondering what shims you guys use to shim the input gears, front and rear? Ive been through two rear input's so far on my kraton and don't really understand why.. and are you shimming behind the diff cup as well? thanks

bennyly

Active Member

Thanks Rich!I generally use 2-3 Kyosho or Tekno bearing shims TKR1222 on the crown gear side bearing to tighten the mesh between the crown and inputs. 3 is sometimes impossible to fit between the diff case and bearing. Usually 2 works just fine. Make sure your diff cover secures down 100% or the diff will move on hard throttle and jack your input. I generally load my gears up with quality synthetic marine grease like Nano Pro MT Marine.

- Thread starter

- #12

Skinso

Active Member

Rich ive seen Thomas's shimming vid which is very good but doesn't mean your diff needs the same shims. My front and rear diffs are shimmed similar to Thomas but my center diff has no shims.

What I do when shimming my diffs is clean it out and apply the gears and shim, screw it all together dry and check how loose/tight it is. You might want to add/remove a shim. Once happy with how it feels apply your lube and good to go

What I do when shimming my diffs is clean it out and apply the gears and shim, screw it all together dry and check how loose/tight it is. You might want to add/remove a shim. Once happy with how it feels apply your lube and good to go