TwiZted SkullZ

Active Member

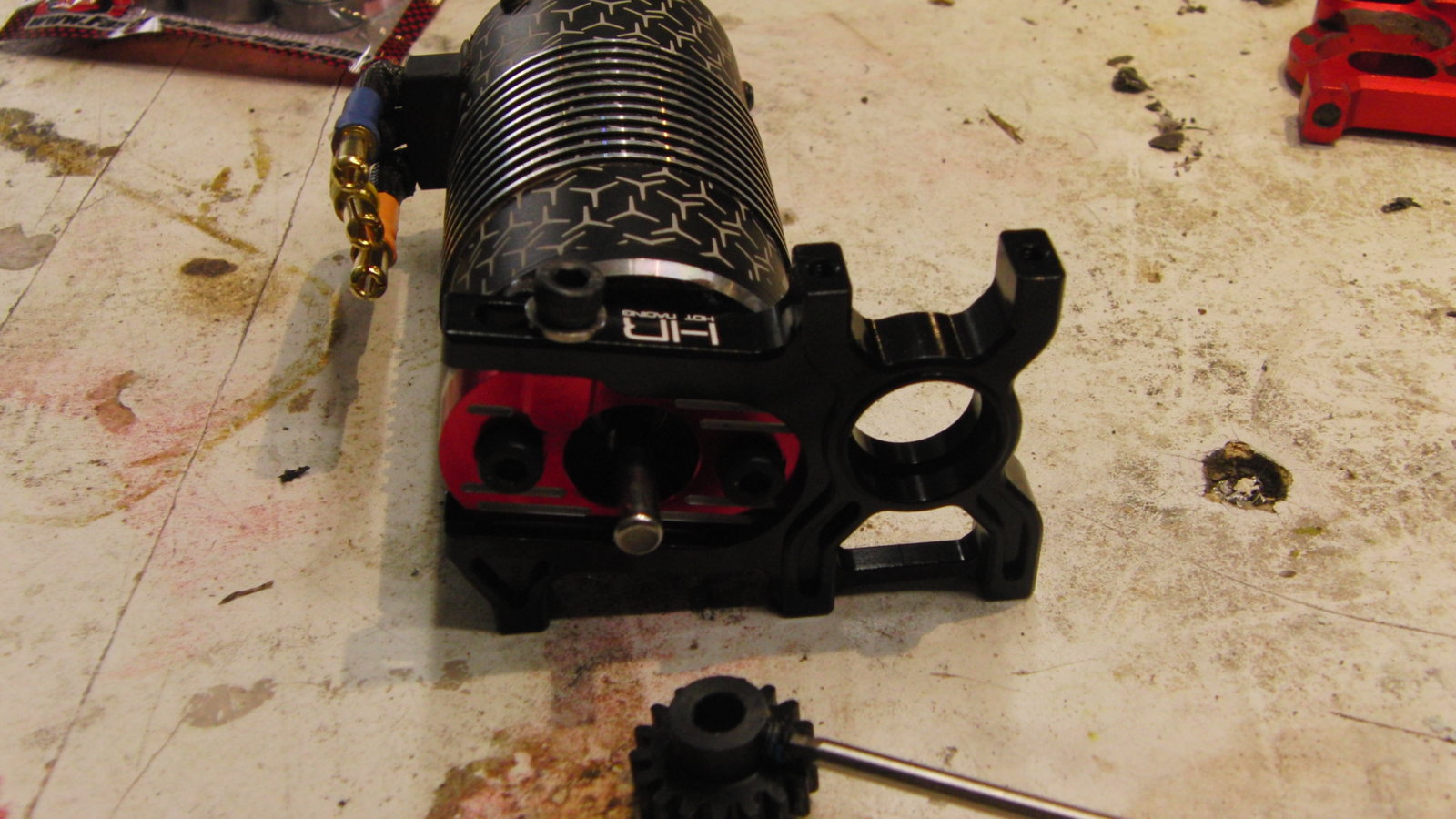

Just got one of those hard to find (what isn't for Arrma) Hot Racing motor mounts for Outcast.

I think they are pretty damn cool and hopefully bullet proof.

Also I figured out how to make an aluminum diff mount from the old Arrma motor mount.

Here ya go!

Starting to add some Fast Eddy bearings to the car too.

The new mount uses different screw holes in the motor

The old motor mount is going to come in very handy,cause the HR diff mounts are buried in King Tuts Tomb!

Cut along the lines.

Bandsaw comes in handy for splittin' things in half!

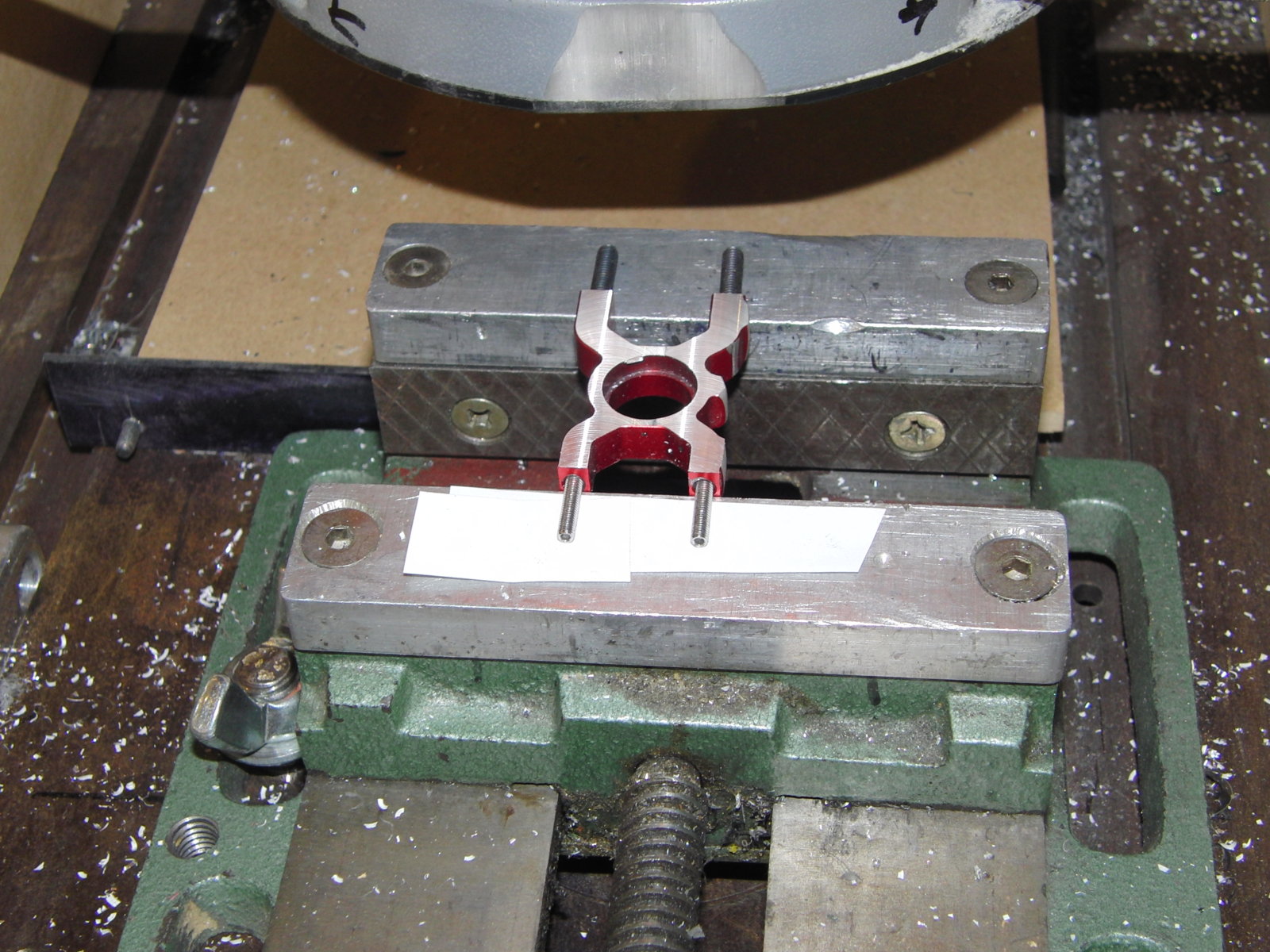

The only problem is,the old mount that I cut off is way too thick so the mounting holes are off by about 2mm or so.

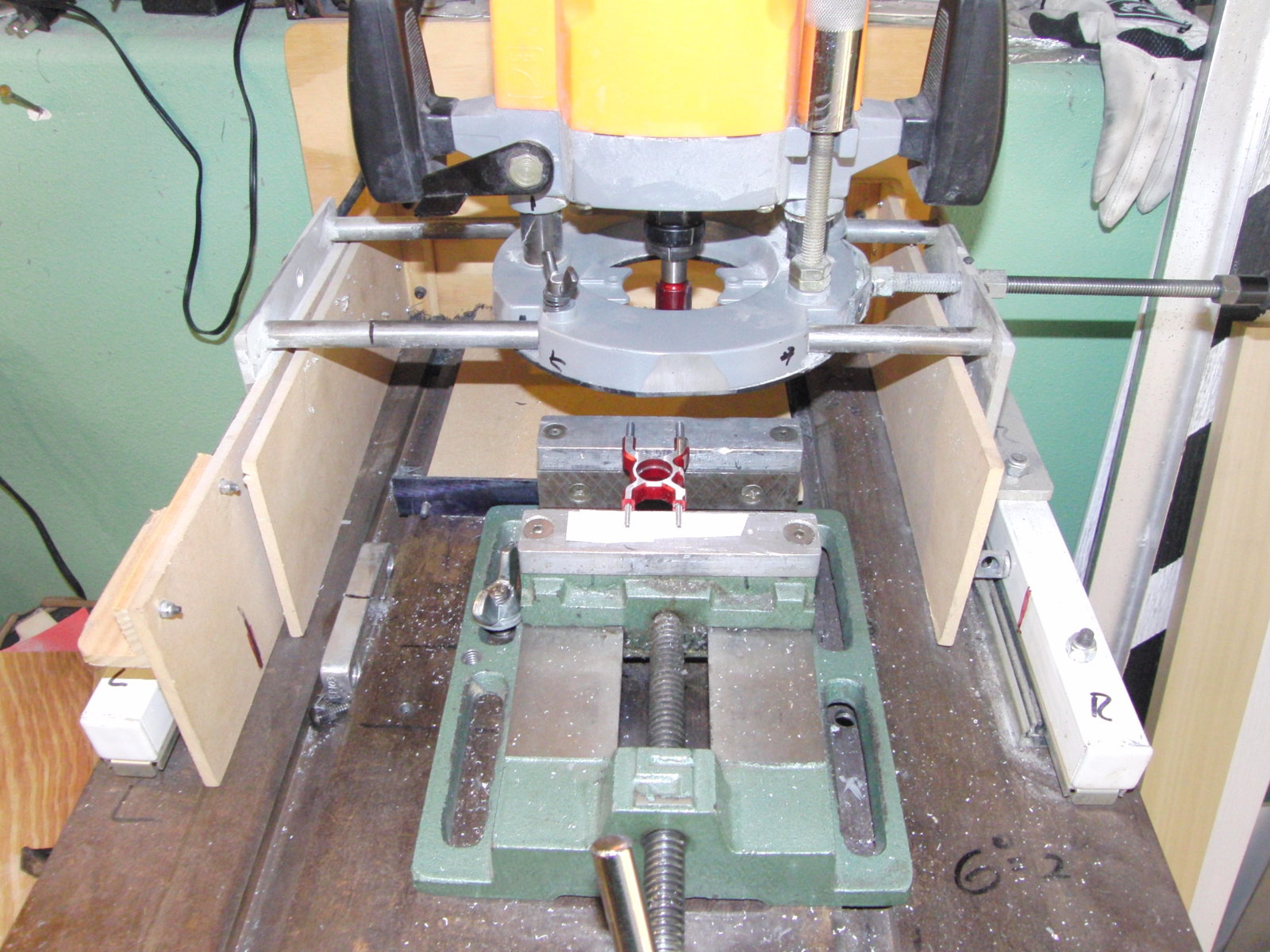

Milling time.....this is an old table saw that I turned into a 2 axis router mill.

Shaved about 2 mil off the bearing side so the holes line up better.

We're not done yet!

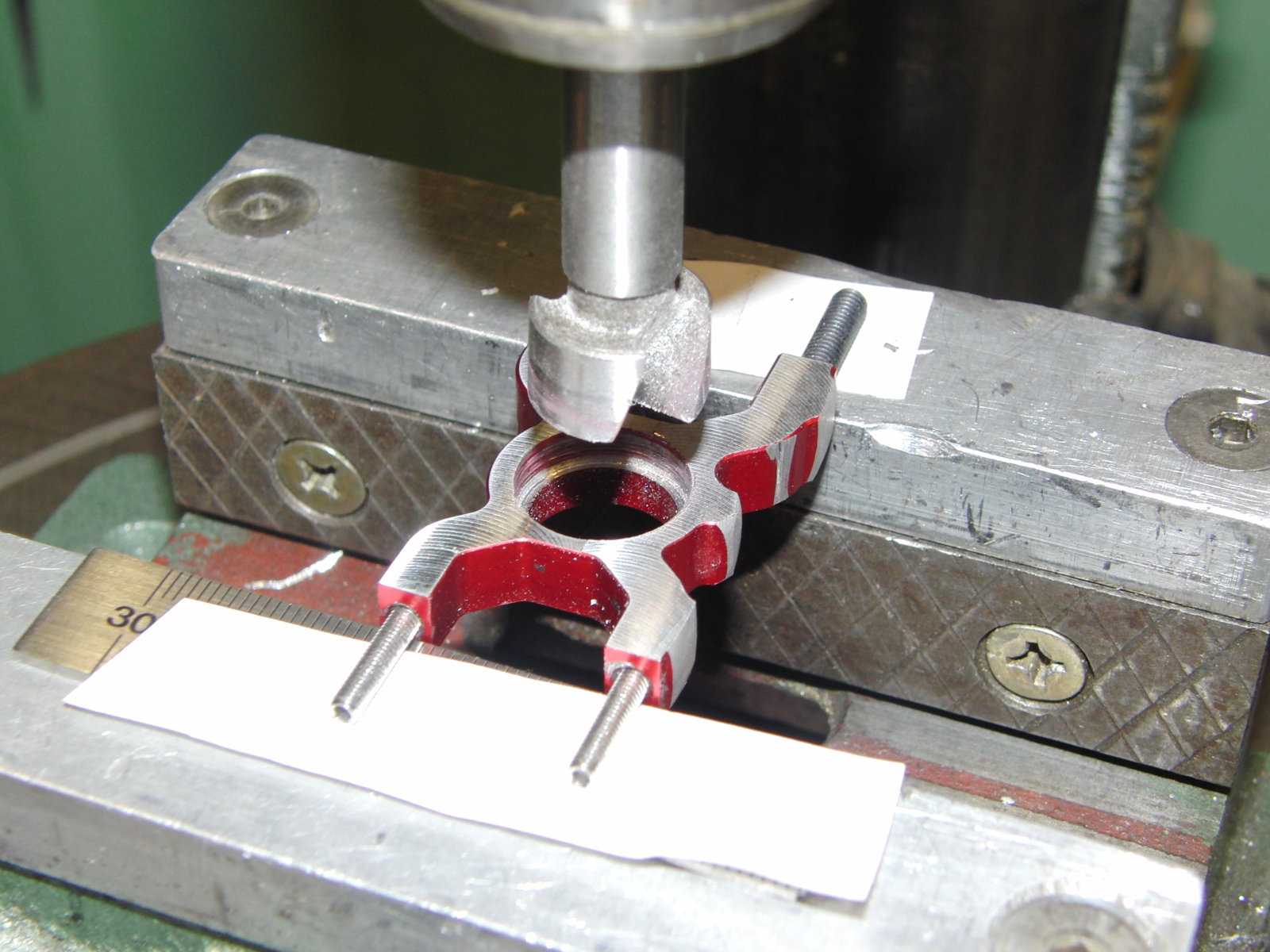

Now the bearing bore needs to go a little deeper so the bearing will seat flush to the mount.

Not having a 5/8" bottom reamer I resorted to using a 5/8" router bit,luckily I only had to take off a few thousandths.

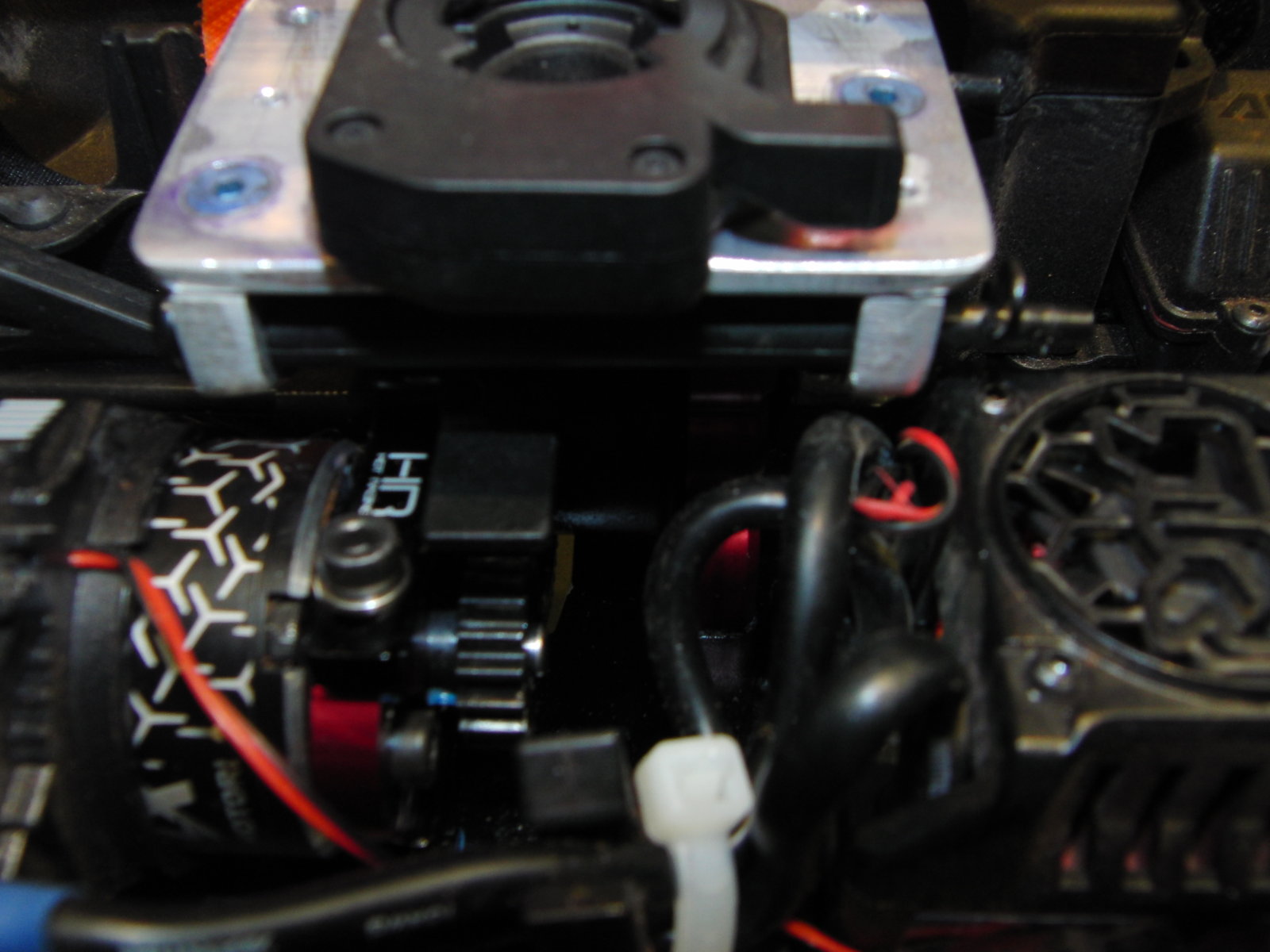

Time to put this baby back together now!

Also this is how I adjust the pinion backlash.

Just take a piece of laser printer paper which is about twice as thick as a regular piece of paper,

and wedge it between the gears and in this case there's only one screw on top to tighten now

Holy crap....IT FITS!!!!

I think Hot Racing made a pretty slick motor mount,and with the right amount of persuasion you might even be able to change the pinion right in the car and make adjust in a matter of minutes!

.

Told you there were a LOT of pics!

I think they are pretty damn cool and hopefully bullet proof.

Also I figured out how to make an aluminum diff mount from the old Arrma motor mount.

Here ya go!

Starting to add some Fast Eddy bearings to the car too.

The new mount uses different screw holes in the motor

The old motor mount is going to come in very handy,cause the HR diff mounts are buried in King Tuts Tomb!

Cut along the lines.

Bandsaw comes in handy for splittin' things in half!

The only problem is,the old mount that I cut off is way too thick so the mounting holes are off by about 2mm or so.

Milling time.....this is an old table saw that I turned into a 2 axis router mill.

Shaved about 2 mil off the bearing side so the holes line up better.

We're not done yet!

Now the bearing bore needs to go a little deeper so the bearing will seat flush to the mount.

Not having a 5/8" bottom reamer I resorted to using a 5/8" router bit,luckily I only had to take off a few thousandths.

Time to put this baby back together now!

Also this is how I adjust the pinion backlash.

Just take a piece of laser printer paper which is about twice as thick as a regular piece of paper,

and wedge it between the gears and in this case there's only one screw on top to tighten now

Holy crap....IT FITS!!!!

I think Hot Racing made a pretty slick motor mount,and with the right amount of persuasion you might even be able to change the pinion right in the car and make adjust in a matter of minutes!

.

Told you there were a LOT of pics!