bricoletout

Member

Hi, here is a tutorial about how I shimmed my diffs.

It could be differents for yours. I hope it is clear enough, my english is not perfect.

There is also the french translation.

http://ambiance-rc-loisir.forumacti...-differentiels-arrma-1-8-kraton-talion-typhon

Thanks to :

@RCROD

@Thomas P

@Rich Duperbash

Adam Drake ("How to" videos)

Also :

https://www.arrmaforum.com/threads/diff-shim-heads-up.3303/

https://www.arrmaforum.com/threads/shims-that-work-for-arrma-diffs.5908/

https://www.arrmaforum.com/threads/help-me-shim-with-mugen-e0206-shim-set.7374/#post-71998

A lot of from the following instructions here comes from these posts/threads/videos.

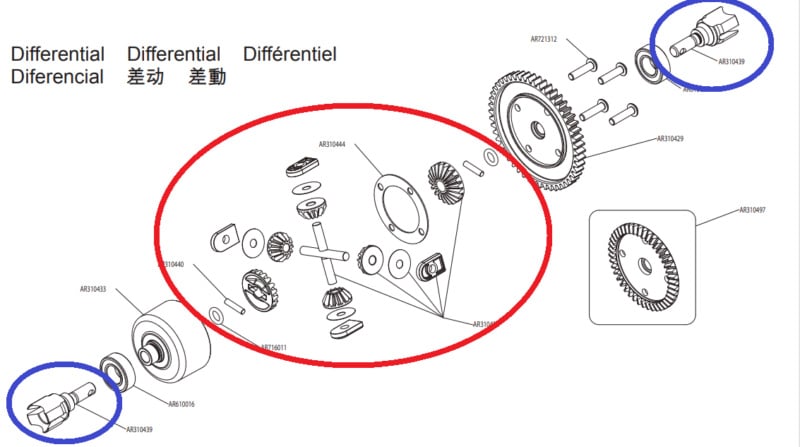

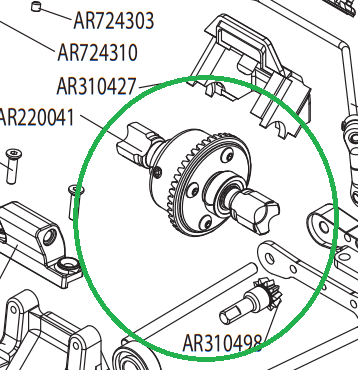

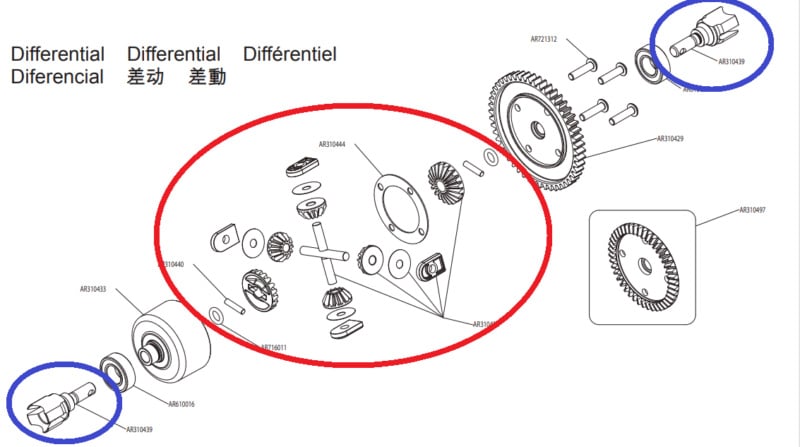

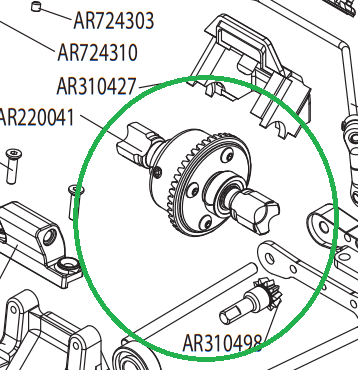

We will shim 3 things :

The planetary with the satellites gear (red),

The diffs outdrives (blue),

The spur diff gear diff with the main input gear (green).

We will need different shims.

Look at this thread to find your shims :

https://www.arrmaforum.com/threads/shims-that-work-for-arrma-diffs.5908/

I used

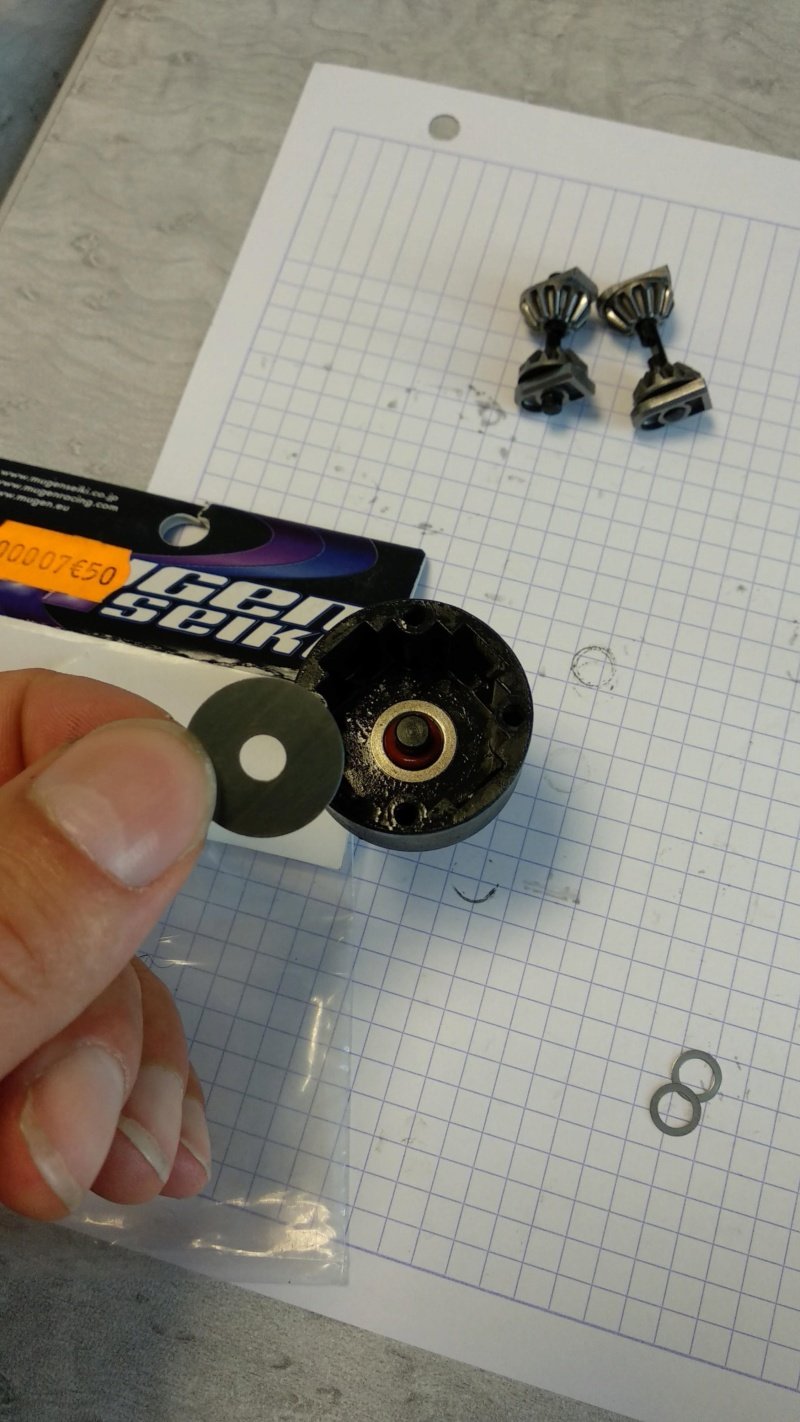

Mugen E0206 for the internal gear (red),

Kyosho KYO96643 5x7mm for the diffs outdrives (blue)

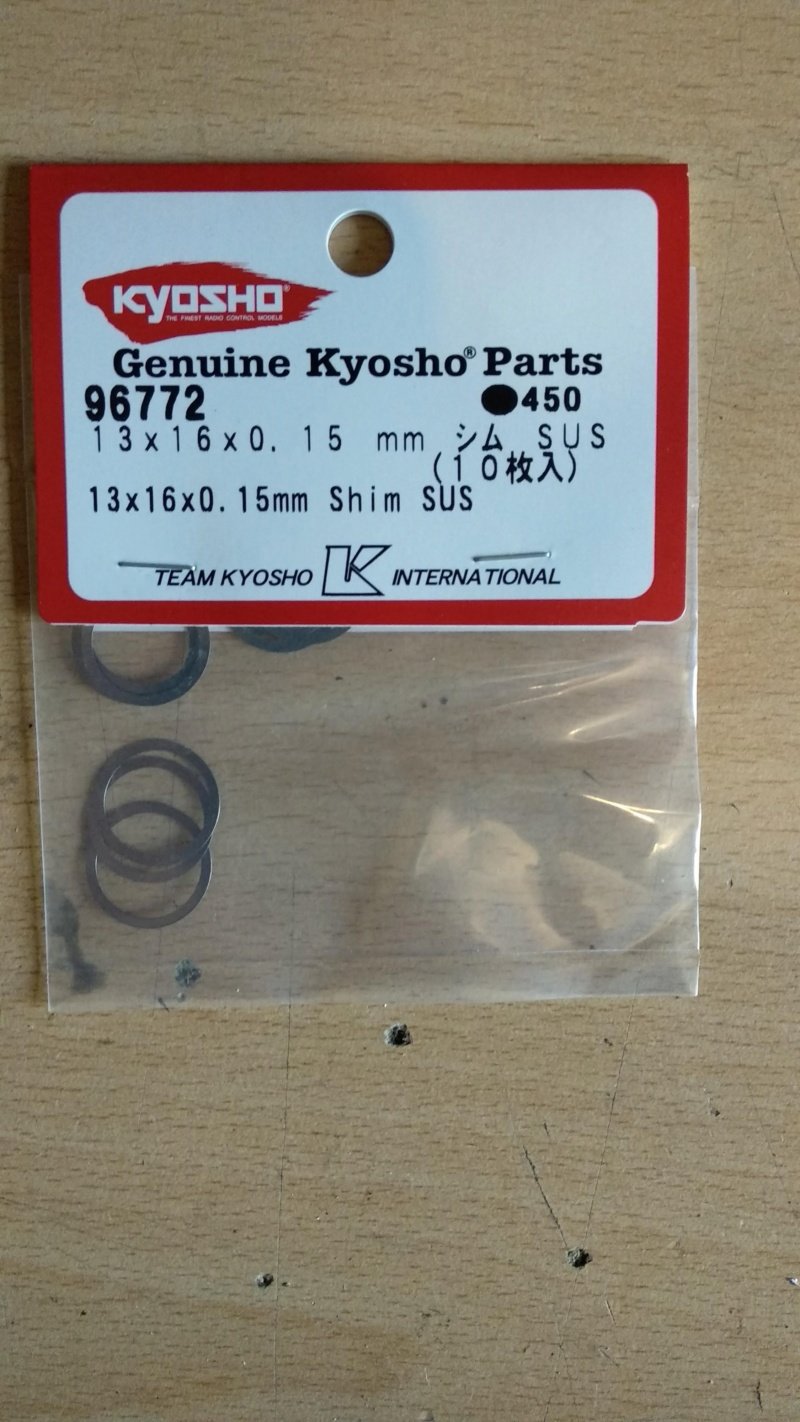

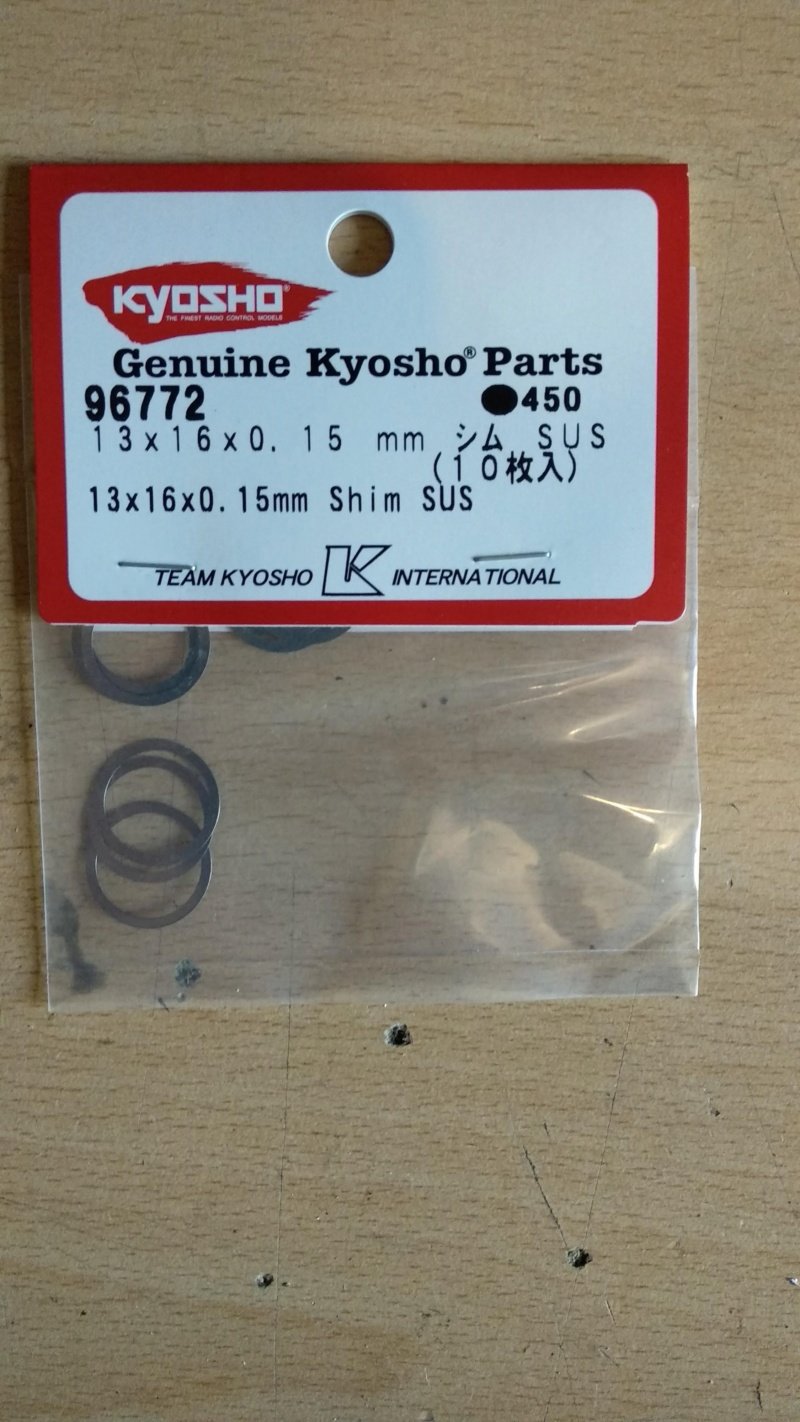

Kyosho KYO96772 for the all diff with the main input gear (green)

Optional cross pin :

2.5mm HSS drill bits to cut 9.5mm (cheap to find on ebay)

Cut them and check their length with the planetary

1 : Dismantle the diffs from the car

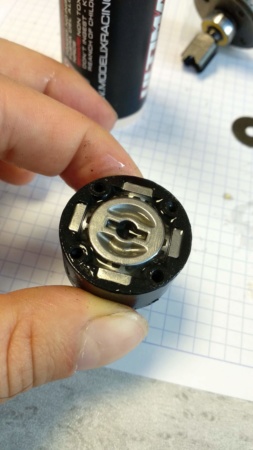

2 :Open the diffs and clean all the parts

Tips :

I let the gear on a kitchen paper and they dried easily and alone in few minutes.

Take care of the DIFF GASKET, don’t tore it !

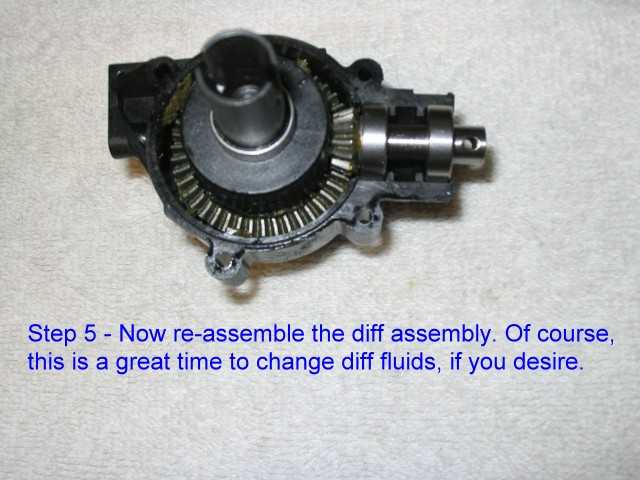

We will rebuild the diff dry first in order to check the diff is not to tight !

It could be differents for yours. I hope it is clear enough, my english is not perfect.

There is also the french translation.

http://ambiance-rc-loisir.forumacti...-differentiels-arrma-1-8-kraton-talion-typhon

Thanks to :

@RCROD

@Thomas P

@Rich Duperbash

Adam Drake ("How to" videos)

Also :

https://www.arrmaforum.com/threads/diff-shim-heads-up.3303/

https://www.arrmaforum.com/threads/shims-that-work-for-arrma-diffs.5908/

https://www.arrmaforum.com/threads/help-me-shim-with-mugen-e0206-shim-set.7374/#post-71998

A lot of from the following instructions here comes from these posts/threads/videos.

We will shim 3 things :

The planetary with the satellites gear (red),

The diffs outdrives (blue),

The spur diff gear diff with the main input gear (green).

We will need different shims.

Look at this thread to find your shims :

https://www.arrmaforum.com/threads/shims-that-work-for-arrma-diffs.5908/

I used

Mugen E0206 for the internal gear (red),

Kyosho KYO96643 5x7mm for the diffs outdrives (blue)

Kyosho KYO96772 for the all diff with the main input gear (green)

Optional cross pin :

2.5mm HSS drill bits to cut 9.5mm (cheap to find on ebay)

Cut them and check their length with the planetary

1 : Dismantle the diffs from the car

2 :Open the diffs and clean all the parts

Tips :

I let the gear on a kitchen paper and they dried easily and alone in few minutes.

Take care of the DIFF GASKET, don’t tore it !

We will rebuild the diff dry first in order to check the diff is not to tight !

Last edited: