Just a Basher

Active Member

- Messages

- 189

- Reaction score

- 377

- Location

- West Palm Beach, FL

- Arrma RC's

- Kraton 6s

- Senton 6s

- Talion

- Typhon 6s

So with the release of the ARRMA V4s, they came out with the "Never Loose" servo saver. I will admit, when I first saw it I was pretty excited, I had issues with my V3 backing off over and over again (until I red loctited it in place). After seeing a few videos, and looking it over myself, it looked like a pretty much non adjustable design. I didn't have any complaints with the servo saver on dirt, but I run a lot of times on grass and asphalt. The out of the box setting just wasn't cutting it on grass and asphalt. I wasn't going to settle for that.

I saw a video here of someone tearing one apart and it looked caked in red loctite. So I wanted to come up with a method of shimming the servo saver without tearing it completely apart.

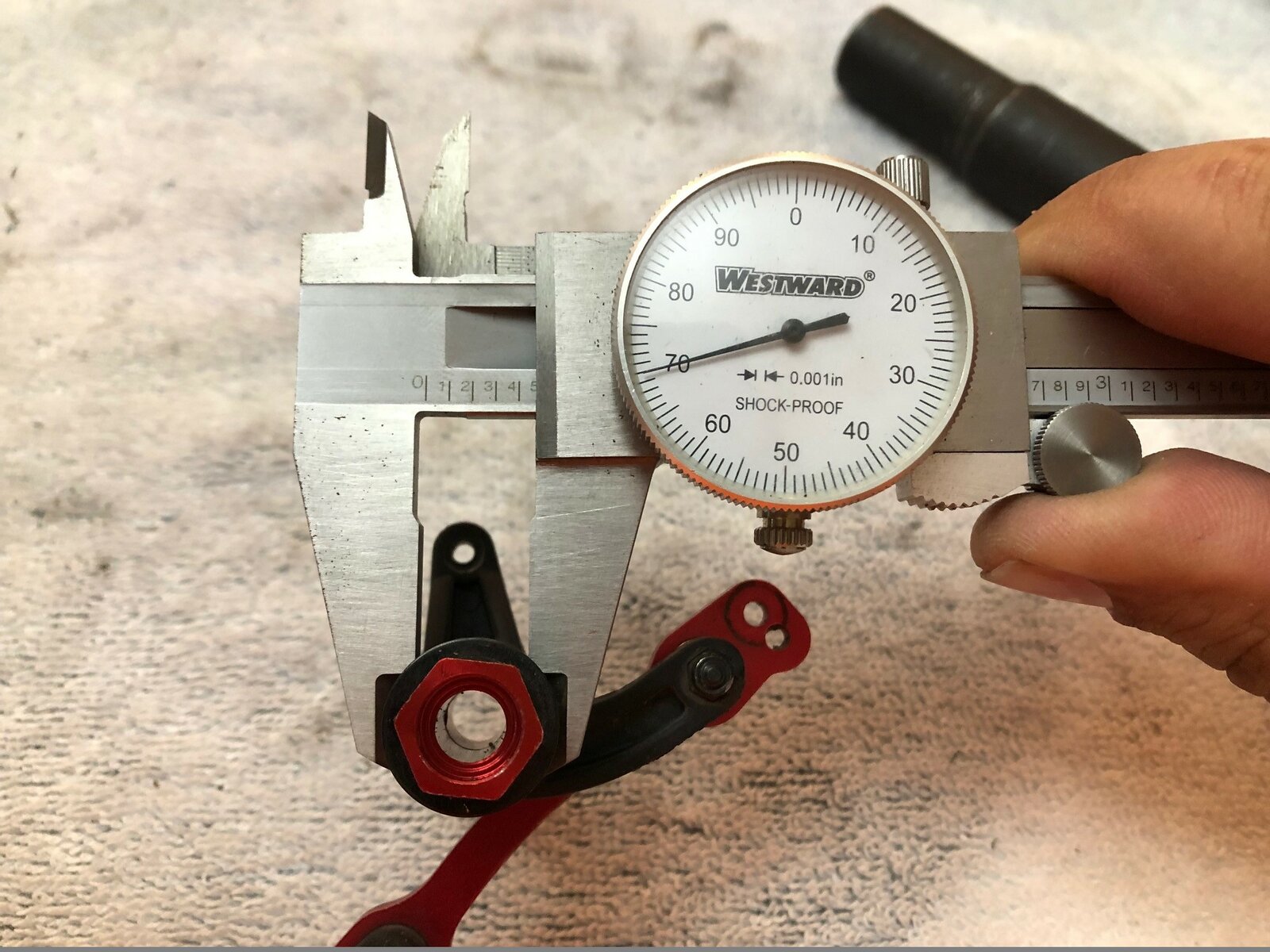

I measured the outside of the post, and its just under 1/2" or 12mm. (I mustered a measurement of 0.468", it looks like 0.47 just due to parallax)

If you wanted to, you would need a washer slightly larger than that to act as a shim to add more force to the servo saver. I still didn't to take it all apart. So out to the garage I went.

Digging through my toolbox I came up with a solution. External snap rings.

I first tried a 1/2" snap ring and it felt way too tight to get it over the head on the post of the servo saver. A 9/16" snap ring seemed to do the job. You should be able to pick these up at a hardware or maybe a home improvement store for around 50 cents.

Now the fun part, if you don't have snap ring pliers this part can get tricky. You can probably use some small allen wrenches that come with a lot of these RC car kits to spread the ends apart and just get it on the head of the post. Like this.

Once you have however many you decide to do (I'm giving 2 a shot first, its easy to add more) take a 1/2" or 13mm socket and push the snap rings down. You will have to push hard enough to compress the spring and the snap rings will be pushed over the bottom of the head, locking in place.

It should look like this (note the bottom snap ring is already in place).

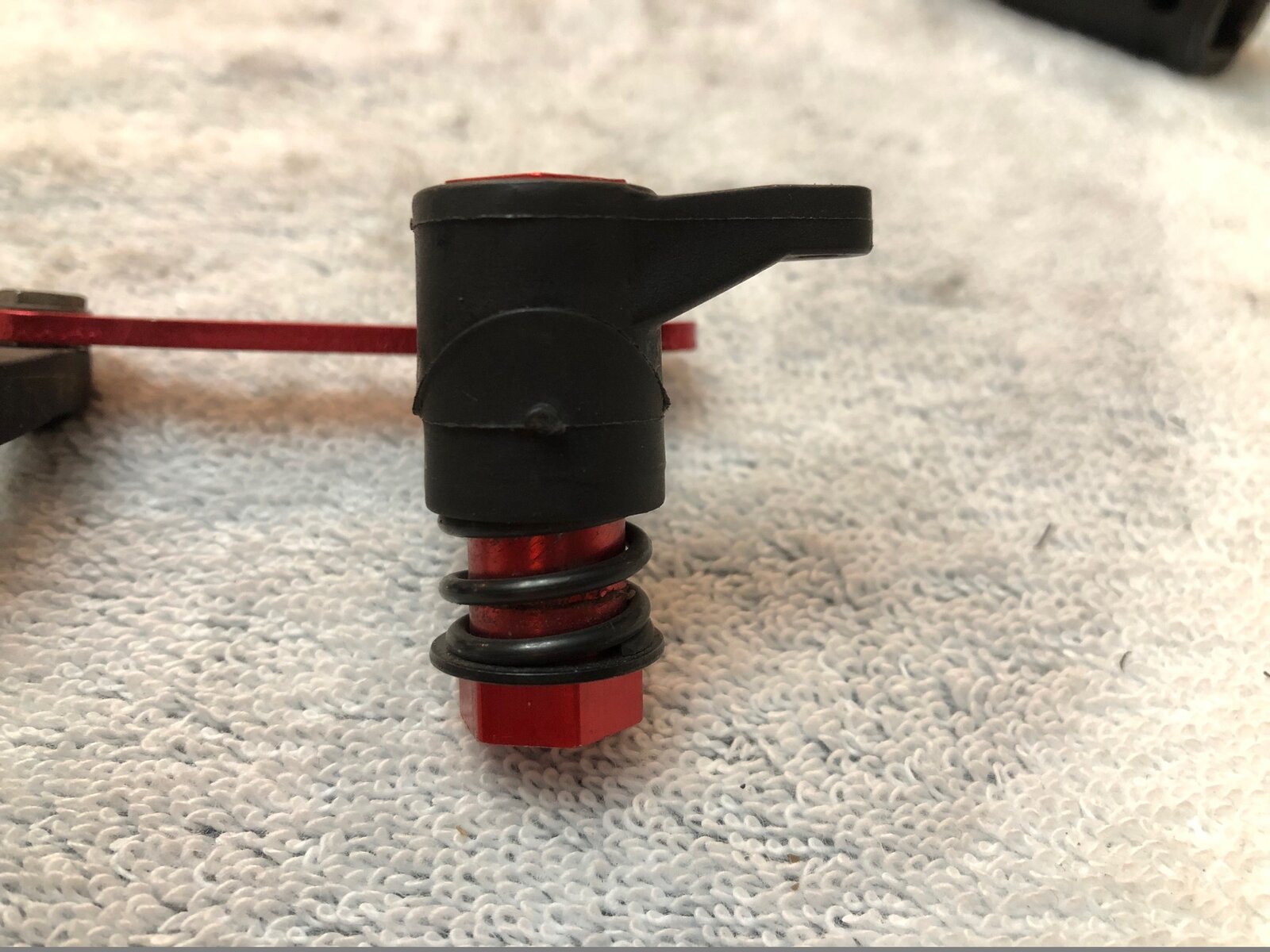

When all is said and done, your assembly should look something like this.

And there you have it. Shimming your V4 Servo Saver. It will also never come loose, as the design intended...and all of that red loctite.

tldr: 9/16" snap ring over the head of the servo saver to adjust spring force.

I saw a video here of someone tearing one apart and it looked caked in red loctite. So I wanted to come up with a method of shimming the servo saver without tearing it completely apart.

I measured the outside of the post, and its just under 1/2" or 12mm. (I mustered a measurement of 0.468", it looks like 0.47 just due to parallax)

If you wanted to, you would need a washer slightly larger than that to act as a shim to add more force to the servo saver. I still didn't to take it all apart. So out to the garage I went.

Digging through my toolbox I came up with a solution. External snap rings.

I first tried a 1/2" snap ring and it felt way too tight to get it over the head on the post of the servo saver. A 9/16" snap ring seemed to do the job. You should be able to pick these up at a hardware or maybe a home improvement store for around 50 cents.

Now the fun part, if you don't have snap ring pliers this part can get tricky. You can probably use some small allen wrenches that come with a lot of these RC car kits to spread the ends apart and just get it on the head of the post. Like this.

Once you have however many you decide to do (I'm giving 2 a shot first, its easy to add more) take a 1/2" or 13mm socket and push the snap rings down. You will have to push hard enough to compress the spring and the snap rings will be pushed over the bottom of the head, locking in place.

It should look like this (note the bottom snap ring is already in place).

When all is said and done, your assembly should look something like this.

And there you have it. Shimming your V4 Servo Saver. It will also never come loose, as the design intended...and all of that red loctite.

tldr: 9/16" snap ring over the head of the servo saver to adjust spring force.