Mr.Duke

Moderator

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 4,223

- Reaction score

- 15,773

- Location

- NC

- Arrma RC's

- Infraction

- Limitless

- Kraton 6s

- Notorious

- Outcast 6s

- Talion

- Typhon 6s

I decided recently that instead of paying someone else to creat a highly detailed custom body for one of my rc's, I would take the plunge and figure out how to hydro dip my own.

I am by no means an expert at any of the following, but after doing it myself and being pleased with the results, I wanted to share a step by step of how I went about the process.

First, let me start out by saying that dipping the inside of an RC body falls outside of how the traditional hydro dipping process works. How this usually works is you have a part or item that you want to dip so the first few steps involve scuffing the part in preparation for a primer coat on the part followed by a base color coat that serves as a backing color for the design printed on the film you'll be dipping with. Because you'll be applying the image to the inside of the body as opposed to the outside, the sequence for application is reversed.

If the traditional hydrodipping process is completely foreign to you, there's a ton of instructional videos out there to watch detailing how this is done when applying to the outside of an item. If you want to dip plastics like a transmitter or other rc related parts these steps will be what you'll follow.

What I'm going to focus on in this thread are the limitations and unique steps that are needed to apply the design to the inside of a polycarbonate body.

Supplies Needed

- Clean, trimmed and final fitted body, ready for paint

- Hydrographic film

This can be purchased from various online sources (just make sure its a quality film from an experienced supplier. I will link down below from the company I purchased my film from)

- Chemical Activator

(purchased from same supplier of hydrographic film)

- Large container to hold water

(I went with a 45 gallon plastic storage bin although the thought of using the bathtub did cross my mind, I chose not to piss off the wife and used a dedicated dipping container instead. Hindsight....this was a wise decision)

- Masking tape

- Razor blade

- Tape measure

- Thermometer

- Timer or stopwatch

- Polycarbonate Spray Paint (for base coat and final backer, such as Tamiya PS line)

Ok.... now that's out of the way, here's the process I used. Again I'm not an expert, this is just what I've gathered from researching online and how it's applied to RC bodies.

Step 1:

You'll need a clean trimmed body ready for paint.

For this example I chose one of my favorites from a looks standpoint, the Redcat Terremoto 10 v2 body that will go on an Arrma Outcast

Since there's already plenty of resources available to get a new body cleaned up, trimmed and ready for paint we're gonna skip all that, and assume everyone already knows everything needed to get to this point.

Step 2:

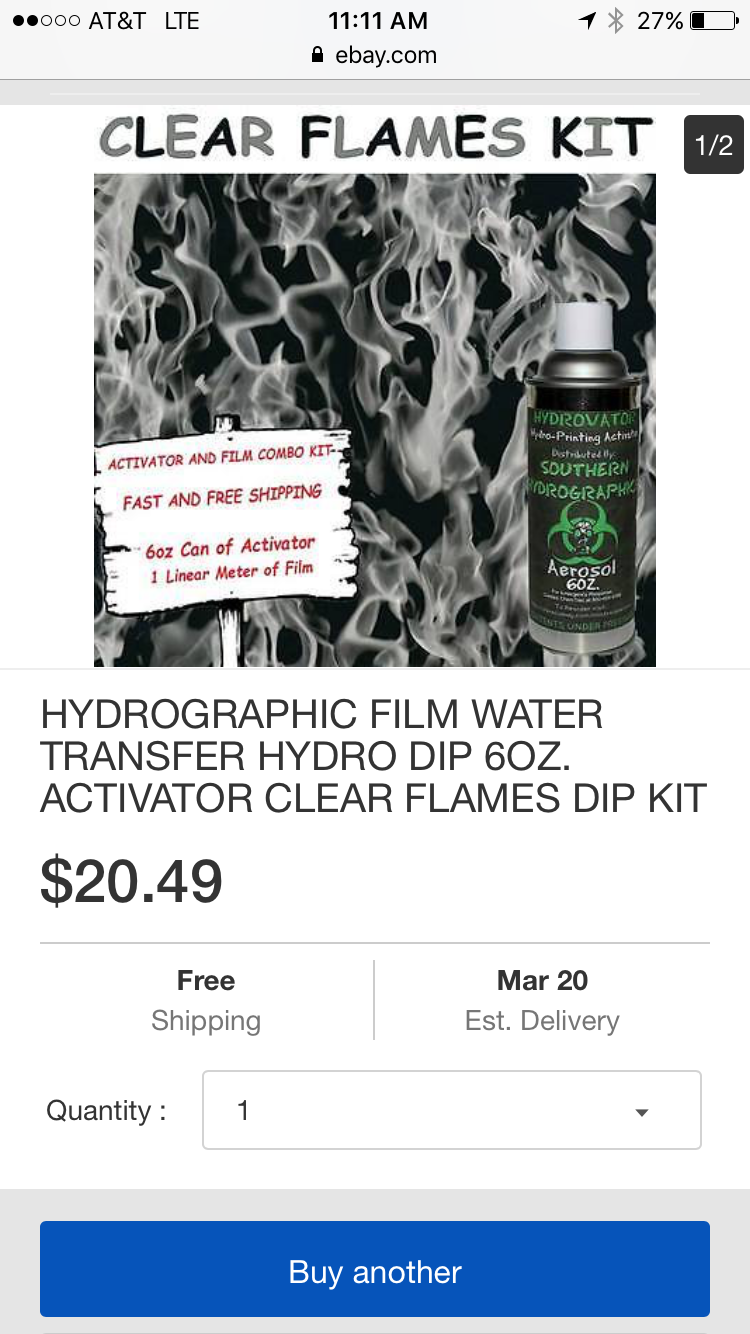

Pick and purchase Hydrographic film and spray activator from a reputable vendor.

There are literally thousands of different designs and prints available to choose from, but I ended up going with a clear flame print so that I could choose the color of the flame

https://www.ebay.com/itm/HYDROGRAPH...MES-DIP-KIT-/253780397155?txnId=2418129585015

This particular film came nicely rolled up in a tube and measures 19" wide x 36" long.

Pay close attention to the size you're buying to make sure it's larger that the item you're dipping.

- once you have the body ready, the film and activator in hand, and a container big enough to fully submerge a body under water, you're ready to start the dipping process.

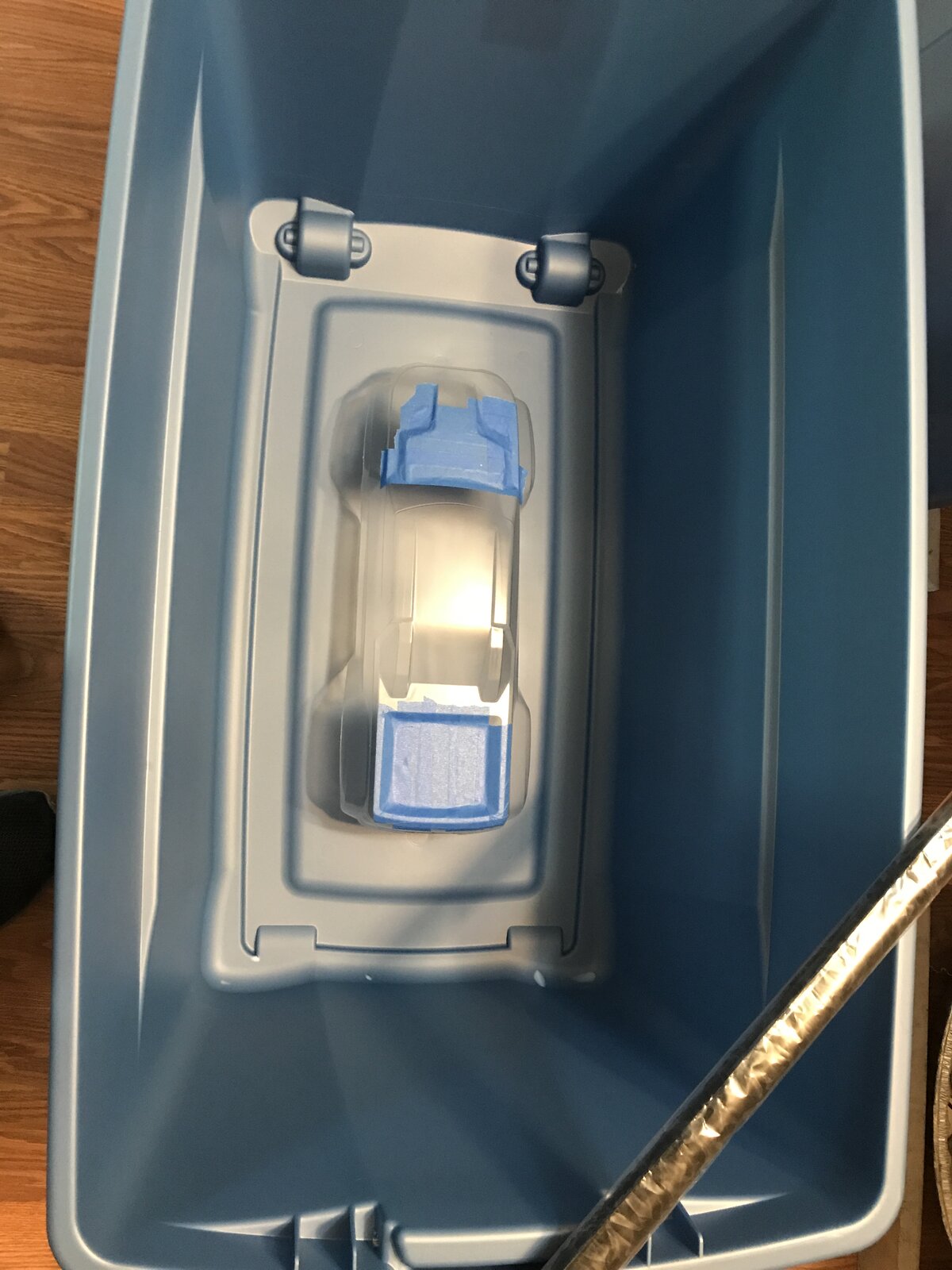

Start by cutting the film down to a size that will not only adequately cover all of the surface area of the inside of the body, but will sit on the surface of the water with only a couple inches of space between the edges of the film and the sides of the dipping container. This is due to the film wanting to spread out once it's activated so you're gonna want to limit the films ability to spread by not giving it enough room to do so, and by taping the edges of the film.

measure cut and tape the edges

Once you have the film prepared you will need figure out which side of the film faces up and which side should face down when placing it on the surface of the water. To do this simply lick the tips of your fingers and pinch a corner of the film to test. The side that that's sticky is the side that faces the water.

Now it's time to fill the dipping container with water making sure that the water temperature is between 80-90F degrees as that's what this particular film manufacturer calls for. I can't speak for all manufacturers recommend water temperature, but dipping at 80-90 degrees seems to be the industry's standard from what I can tell.

You also need to make sure that the water is deep enough to completely submerge the body under the water line.

Now that everything is ready and the water temp in my case was 89 degrees, it's time to lay the film on top of the water making sure to push out any big air bubbles trapped under the film and smooth any wrinkles that develop. Do not let water on top of the film during this part as it will dilute the activator and cause problems with adhesion of the design to the body.

These next few steps are important and time sensitive, which is where the stopwatch comes in.

Once the film has been placed on top of the water you have 60 seconds to remove any air bubbles and move the film around gently to get any wrinkles out that start forming. Any wrinkles left on the film will create a flaw on the finished product.

Once the the film has been placed on the surface of the water for 60 seconds you will spray the activator 8-12" straight down on the surface of the film, only overlapping passes by at most 20%.

At this point the film will dissolve and turn into a liquid state. You have 15-30 seconds to dip your body after spraying the activator.

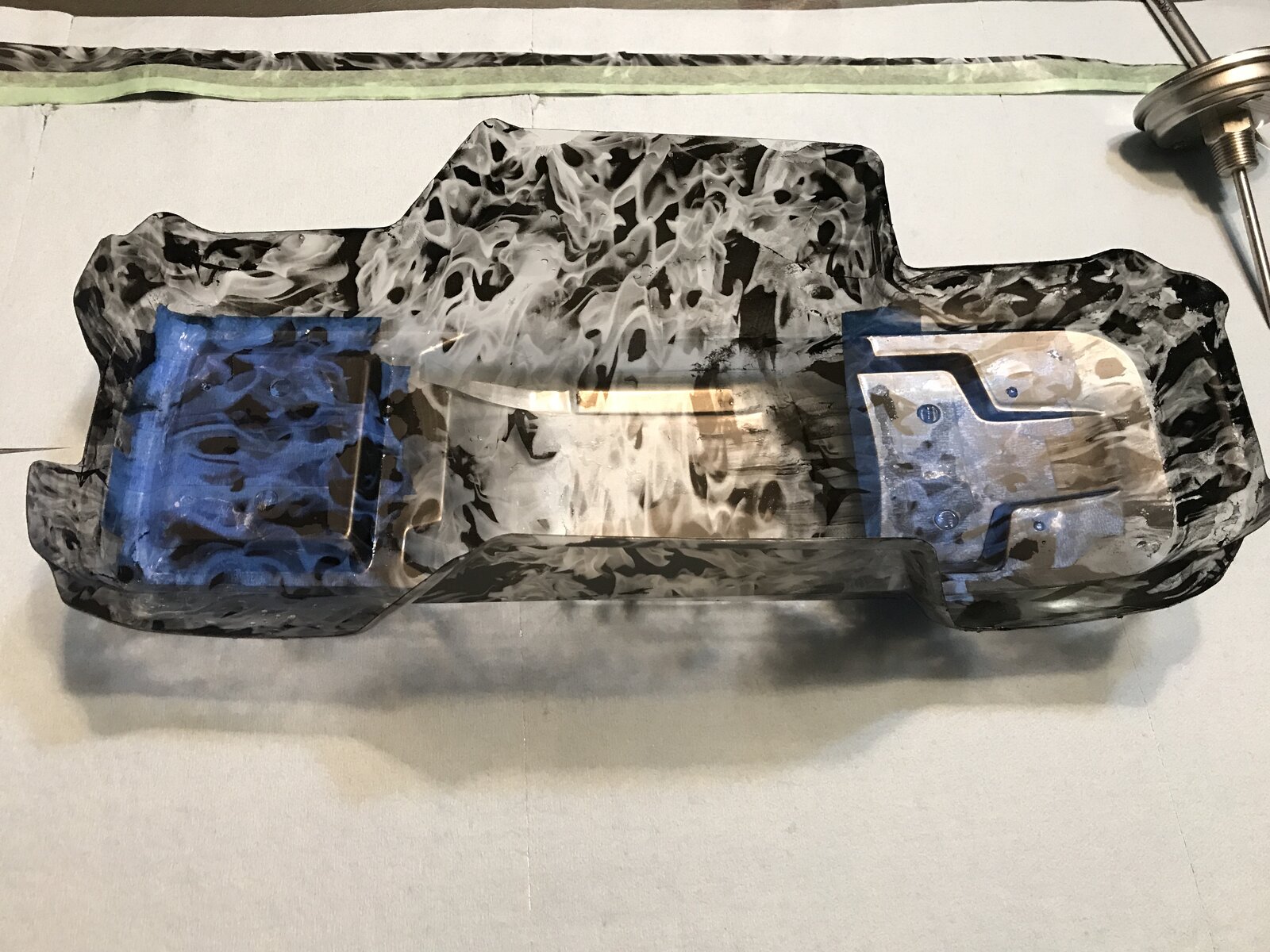

Lower the body into the water at an angle between 30-45 degrees and in a steady motion slowly lower it into the water until its completely submerged.

Move the body in circular motions while its submerged to break off any loose parts of the film or tape and to create a somewhat clear area the bring the body up out of the water.

Once the body is out of the water take it directly to a sink and run the inside of the body under warm water for 3 minutes to wash off the slime and residue from the dipping process. You will know it all washed off once it has dried and the pattern has taken on a dull sheen. If you see any wet looking areas rewash with warm water until it dries dull everywhere.

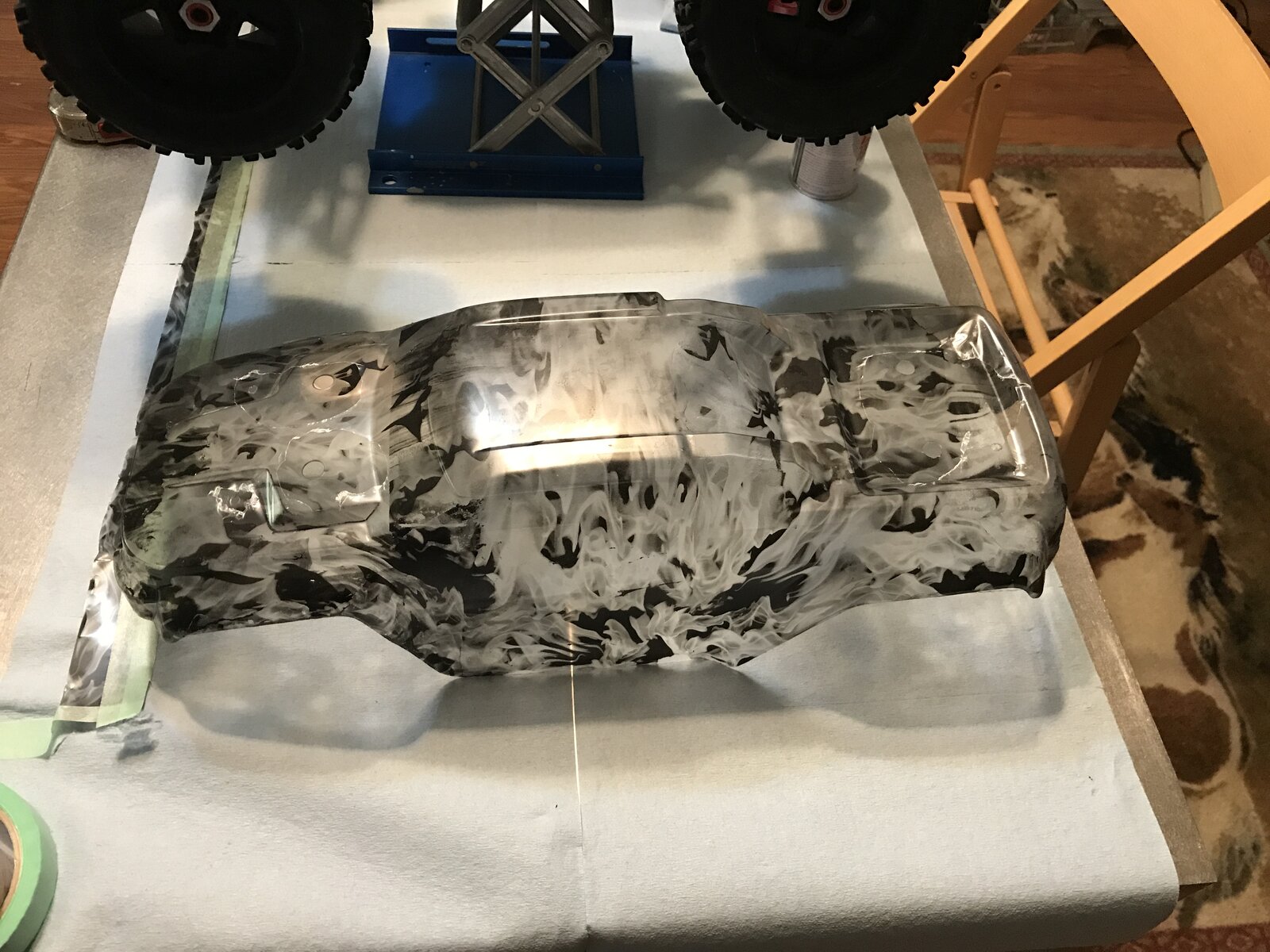

Here's how mine turned out

That concludes the dipping portion of this process and the rest will be standard painting procedures.

In my case I wanted red flames so after waiting a day (probably not necessary but in my case the humidity was too high to spray until the following day) I was finally able to apply the red base coat.

^ After the 4th light coat of Red (Tamiya PS-2)

I am by no means an expert at any of the following, but after doing it myself and being pleased with the results, I wanted to share a step by step of how I went about the process.

First, let me start out by saying that dipping the inside of an RC body falls outside of how the traditional hydro dipping process works. How this usually works is you have a part or item that you want to dip so the first few steps involve scuffing the part in preparation for a primer coat on the part followed by a base color coat that serves as a backing color for the design printed on the film you'll be dipping with. Because you'll be applying the image to the inside of the body as opposed to the outside, the sequence for application is reversed.

If the traditional hydrodipping process is completely foreign to you, there's a ton of instructional videos out there to watch detailing how this is done when applying to the outside of an item. If you want to dip plastics like a transmitter or other rc related parts these steps will be what you'll follow.

What I'm going to focus on in this thread are the limitations and unique steps that are needed to apply the design to the inside of a polycarbonate body.

Supplies Needed

- Clean, trimmed and final fitted body, ready for paint

- Hydrographic film

This can be purchased from various online sources (just make sure its a quality film from an experienced supplier. I will link down below from the company I purchased my film from)

- Chemical Activator

(purchased from same supplier of hydrographic film)

- Large container to hold water

(I went with a 45 gallon plastic storage bin although the thought of using the bathtub did cross my mind, I chose not to piss off the wife and used a dedicated dipping container instead. Hindsight....this was a wise decision)

- Masking tape

- Razor blade

- Tape measure

- Thermometer

- Timer or stopwatch

- Polycarbonate Spray Paint (for base coat and final backer, such as Tamiya PS line)

Ok.... now that's out of the way, here's the process I used. Again I'm not an expert, this is just what I've gathered from researching online and how it's applied to RC bodies.

Step 1:

You'll need a clean trimmed body ready for paint.

For this example I chose one of my favorites from a looks standpoint, the Redcat Terremoto 10 v2 body that will go on an Arrma Outcast

Since there's already plenty of resources available to get a new body cleaned up, trimmed and ready for paint we're gonna skip all that, and assume everyone already knows everything needed to get to this point.

Step 2:

Pick and purchase Hydrographic film and spray activator from a reputable vendor.

There are literally thousands of different designs and prints available to choose from, but I ended up going with a clear flame print so that I could choose the color of the flame

https://www.ebay.com/itm/HYDROGRAPH...MES-DIP-KIT-/253780397155?txnId=2418129585015

This particular film came nicely rolled up in a tube and measures 19" wide x 36" long.

Pay close attention to the size you're buying to make sure it's larger that the item you're dipping.

- once you have the body ready, the film and activator in hand, and a container big enough to fully submerge a body under water, you're ready to start the dipping process.

Start by cutting the film down to a size that will not only adequately cover all of the surface area of the inside of the body, but will sit on the surface of the water with only a couple inches of space between the edges of the film and the sides of the dipping container. This is due to the film wanting to spread out once it's activated so you're gonna want to limit the films ability to spread by not giving it enough room to do so, and by taping the edges of the film.

measure cut and tape the edges

Once you have the film prepared you will need figure out which side of the film faces up and which side should face down when placing it on the surface of the water. To do this simply lick the tips of your fingers and pinch a corner of the film to test. The side that that's sticky is the side that faces the water.

Now it's time to fill the dipping container with water making sure that the water temperature is between 80-90F degrees as that's what this particular film manufacturer calls for. I can't speak for all manufacturers recommend water temperature, but dipping at 80-90 degrees seems to be the industry's standard from what I can tell.

You also need to make sure that the water is deep enough to completely submerge the body under the water line.

Now that everything is ready and the water temp in my case was 89 degrees, it's time to lay the film on top of the water making sure to push out any big air bubbles trapped under the film and smooth any wrinkles that develop. Do not let water on top of the film during this part as it will dilute the activator and cause problems with adhesion of the design to the body.

These next few steps are important and time sensitive, which is where the stopwatch comes in.

Once the film has been placed on top of the water you have 60 seconds to remove any air bubbles and move the film around gently to get any wrinkles out that start forming. Any wrinkles left on the film will create a flaw on the finished product.

Once the the film has been placed on the surface of the water for 60 seconds you will spray the activator 8-12" straight down on the surface of the film, only overlapping passes by at most 20%.

At this point the film will dissolve and turn into a liquid state. You have 15-30 seconds to dip your body after spraying the activator.

Lower the body into the water at an angle between 30-45 degrees and in a steady motion slowly lower it into the water until its completely submerged.

Move the body in circular motions while its submerged to break off any loose parts of the film or tape and to create a somewhat clear area the bring the body up out of the water.

Once the body is out of the water take it directly to a sink and run the inside of the body under warm water for 3 minutes to wash off the slime and residue from the dipping process. You will know it all washed off once it has dried and the pattern has taken on a dull sheen. If you see any wet looking areas rewash with warm water until it dries dull everywhere.

Here's how mine turned out

That concludes the dipping portion of this process and the rest will be standard painting procedures.

In my case I wanted red flames so after waiting a day (probably not necessary but in my case the humidity was too high to spray until the following day) I was finally able to apply the red base coat.

^ After the 4th light coat of Red (Tamiya PS-2)

Last edited: