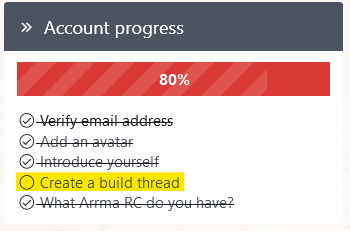

I figured I would start a build thread, not because I'm special or talented or will break a speed record, but mainly because the Arrma forums keep bugging me. Also I might keep you somewhat entertained with my mistakes. My self image of myself as a maker far exceeds my talent. .

And so here it starts. . . My first goal is to build a car that I can break 100 MPH in San Jose. The In San Jose is a very difficult clause, because we have way too many people and cars then add in the roads are in general mayhem. Not Manhatten pothole mayhem, just general disrepair. I'm still looking, perhaps a nice parking lot will work? If you have ideas or location please send them.

First things first I needed some info. So I went straight to YouTube and started watching Raz Shifrin. He does extremely clean work and runs fast. Oh, it looks like he's got really nice apartment in Israel too. Found some others like Innovation RC who is a little experimental and James McCoy who runs like lighting. Many thanks to all the YT knowledge out there.

From there I followed his 150MPH build and as a template, cleaned off my workbench and headed out. I'm making a conscious effort to give money to my local hobby store, thanks Norcal Hobbies. Amain gets plenty of my money and if we want local hobby stores to support us, we need to support them. So off I went and I picked up the Limitless kit, ESC, Motor, servo and some misc stuff.

Aside from some misc stuff, like tools my build list is below.

I'm waiting on

And so here it starts. . . My first goal is to build a car that I can break 100 MPH in San Jose. The In San Jose is a very difficult clause, because we have way too many people and cars then add in the roads are in general mayhem. Not Manhatten pothole mayhem, just general disrepair. I'm still looking, perhaps a nice parking lot will work? If you have ideas or location please send them.

First things first I needed some info. So I went straight to YouTube and started watching Raz Shifrin. He does extremely clean work and runs fast. Oh, it looks like he's got really nice apartment in Israel too. Found some others like Innovation RC who is a little experimental and James McCoy who runs like lighting. Many thanks to all the YT knowledge out there.

From there I followed his 150MPH build and as a template, cleaned off my workbench and headed out. I'm making a conscious effort to give money to my local hobby store, thanks Norcal Hobbies. Amain gets plenty of my money and if we want local hobby stores to support us, we need to support them. So off I went and I picked up the Limitless kit, ESC, Motor, servo and some misc stuff.

Aside from some misc stuff, like tools my build list is below.

| Brand | Part Number | Description | Qty | Cost | Ext |

| Arrma | ARA109011 | Limitless Roller | 1 | $399.99 | $399.99 |

| Castle | 010-0167-00 | XLX2 ESC | 1 | $269.95 | $269.95 |

| Castle | 060-0082-00 | 1717 1650 Brushless Motor | 1 | $209.95 | $209.95 |

| Castle | CSE010-0149-00 | Castle Link Data Port | 1 | $19.49 | $19.49 |

| SkyRC | GNSS Performance Analyzer | 1 | $79.99 | $79.99 | |

| ProTek | PTK-130T | Standard Digital "High Torque" Metal Gear Servo | 1 | $89.99 | $89.99 |

| RadioLink | RC6GS V2 6 | 6 Channels RC Transmitter and Gyro Receiver R7FG | 1 | $79.99 | $79.99 |

| ProTek | PTK-5071 | QS8 Connector | 2 | $11.00 | $22.00 |

| CNHL | 950904QS8 | Battery | 2 | $99.99 | $199.98 |

| 3M | SJ3560 | Dual Lock | 1 | $23.99 | $23.99 |

| Saga | 32T5MM | 32T 5MM MOD-1 Saga Pinion | 1 | $20.99 | $20.99 |

| Saga | 36T5MM | 36T 5MM MOD-1 SAGA PINION | 1 | $20.99 | $20.99 |

| PPS | ppsgrub25mm30mm | Custom Motor Mount | 1 | $109.95 | $109.95 |

| Powerhobby | PH1289BLUE | Dual Fan | 1 | $22.95 | $22.95 |

| Ebay | ESC Center Brace | 1 | $24.99 | $24.99 | |

| 1x1x36" aluminum angle | 1 | $17.99 | $17.99 | ||

| Total | $1,547.25 |

- the batteries from CNHL

- pinions and Motor Mount from Island Hobby

- fans some balance leads from Norcal Hobby