Gedrick

Very Active Member

This may be amateur hour stuff for you folks who've been into RC for a while, but I posted about this in RazorRCs thread and it's probably buried by now.

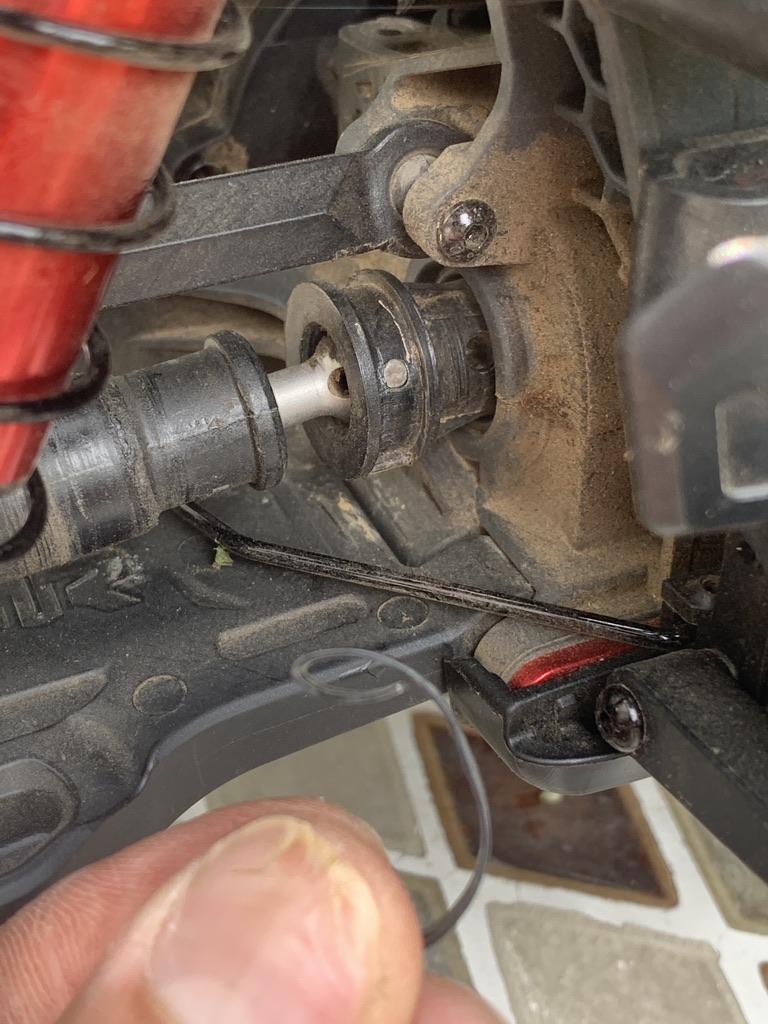

I ran my Kraton through only one battery pack and found that a common issue others had with the driveshafts also happened to me - popped off C-clips, leaving the pin exposed, like so:

These clips retain the pin that the driveshafts pivot around where they meet the diff outdrive. This could potentially end up in the pin coming out (since the c-clip covers it and holds it in), and the shaft being busted until some replacements could be shipped.

I was lucky that I still had the clip itself, and although it was mangled I was able to get the thing back into shape and clipped back on somehow - losing only about 2-3mm of the clip itself due to metal fatigue when I bent it back. However now it was basically guaranteed to come back off, so I tried putting a zip tie around it. This worked great -- until of course, the wheel spun, and then the block part of the zip tie would hit and wear down the tie rod.

Then I tried some electrical tape. This held up great in the front, but due to the stickiness of tape it got very gritty from roost and eventually failed after a single battery pack. Not to mention was a total disaster to clean up, attracting all the gritty dirt right into high speed moving metal parts..

Finally I went to the 'Depot and got some FAT heat shrink. Talking the thickest I could find. Thicker than a bowl of oatmeal.

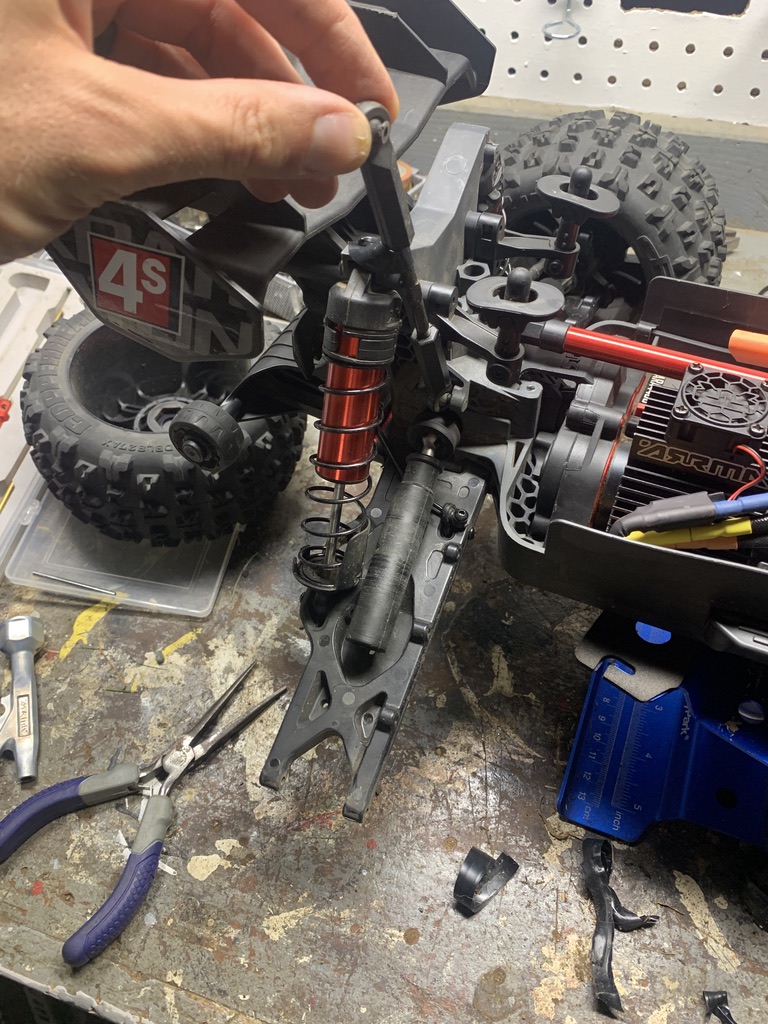

The fronts were very easy to do, because you can get your hex down into the groove, pull out the grub screw, and the driveshaft popped out easy. I cut a thin strip of the smaller heat shrink and it went on great. Fronts were done.

The rear, you can't really get a hex into the grub to remove the shaft, honestly I don't even know how I'm supposed to get here. But I was able to remove the tire and the rear hub, allowing me to pull out the tire-side of the driveshaft, so I could slide on the heat shrink towards the diff.

All in all, this went on very easily and I don't anticipate further problems unless this heat shrink fails, which seems pretty unlikely for a while due to how darn thick it is.

There ya have it. Wanted to break this out into a post in case some concerned Googler with the same problem comes along. Thanks for watching and I'll see you next time.

I ran my Kraton through only one battery pack and found that a common issue others had with the driveshafts also happened to me - popped off C-clips, leaving the pin exposed, like so:

These clips retain the pin that the driveshafts pivot around where they meet the diff outdrive. This could potentially end up in the pin coming out (since the c-clip covers it and holds it in), and the shaft being busted until some replacements could be shipped.

I was lucky that I still had the clip itself, and although it was mangled I was able to get the thing back into shape and clipped back on somehow - losing only about 2-3mm of the clip itself due to metal fatigue when I bent it back. However now it was basically guaranteed to come back off, so I tried putting a zip tie around it. This worked great -- until of course, the wheel spun, and then the block part of the zip tie would hit and wear down the tie rod.

Then I tried some electrical tape. This held up great in the front, but due to the stickiness of tape it got very gritty from roost and eventually failed after a single battery pack. Not to mention was a total disaster to clean up, attracting all the gritty dirt right into high speed moving metal parts..

Finally I went to the 'Depot and got some FAT heat shrink. Talking the thickest I could find. Thicker than a bowl of oatmeal.

The fronts were very easy to do, because you can get your hex down into the groove, pull out the grub screw, and the driveshaft popped out easy. I cut a thin strip of the smaller heat shrink and it went on great. Fronts were done.

The rear, you can't really get a hex into the grub to remove the shaft, honestly I don't even know how I'm supposed to get here. But I was able to remove the tire and the rear hub, allowing me to pull out the tire-side of the driveshaft, so I could slide on the heat shrink towards the diff.

All in all, this went on very easily and I don't anticipate further problems unless this heat shrink fails, which seems pretty unlikely for a while due to how darn thick it is.

There ya have it. Wanted to break this out into a post in case some concerned Googler with the same problem comes along. Thanks for watching and I'll see you next time.

Last edited: