Sounds like you have it over-filled. Take the grub screw out on the side of the housing, rotate it so that hole is up, and then tighten it. If it is still locking up when tightened you have too many shims or something is not fitting together properly.So I’m getting this lockout of the diff often (or just way too stiff action that “pops” or jumps as opposed to the smoother chatter or click of the LSD effect) when I tighten the screws down final. If I loosen them just a little the diff feels fine and all is good, so I know there isn’t a damaged gear causing bad mesh or anything. It’s definitely just the compression of the system when screwed tight. I’d just go with loosening them but oil is leaking from the screws when I do (doesn’t take much loosening for oil to dribble out). I’m about to try this “cracking” method but obviously a little nervous as this doesn’t sound normal at all. Not to distrust you here spoc but anyone else confirm this is a safe and logical maneuver? Typically I’m against brute force methods just cause it shouldn’t be necessary.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kraton Kraton 6S EXB Diff Shim Set to Open Diff - Beware

- Thread starter parcou

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

I got some exb lsd diffs from Jenny's. When I turn them by hand there is a spot where it sorta feels gritty, not smooth. Both diffs do this so I assume normal.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,877

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

Not having messed with LSD's before, but reading between the lines here, The Star plates are chamfered at one end. So the chamfered edges are directionally positioned. Also LSD 's run best with thinner oil. Many see better results. Thicker oil will just lock it up more. Where the LSD plates for the most part are supposed to dial in the diff action. By contrast, a standard Non LSD diff requires the use of thicker or thinner oil as needed to dial in the diff action the way you like it.

Also, if screwed too loose, the parts will be looser, Diff will appear smoother, but the diff overall will be compromised at some point sooner than later. Leakage and excess wear will result.

I also found that all diffs have a break-in period, before they ultimately become smoother, less ratchety.

I like to empty and refill them after a decent break-in. Removing break-in metals floating around in the oil. Just dumping the oil and a refill without complete removal of the internal parts or whole dissassembly of the diff. Just me.

Also, if screwed too loose, the parts will be looser, Diff will appear smoother, but the diff overall will be compromised at some point sooner than later. Leakage and excess wear will result.

I also found that all diffs have a break-in period, before they ultimately become smoother, less ratchety.

I like to empty and refill them after a decent break-in. Removing break-in metals floating around in the oil. Just dumping the oil and a refill without complete removal of the internal parts or whole dissassembly of the diff. Just me.

parcou

Premium Member!

Premium Member

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 6,223

- Reaction score

- 9,124

- Location

- Memphis, TN

- Arrma RC's

- BigRock

- Felony

- Fireteam

- Granite

- Infraction

- Kraton EXB

- Talion EXB

- Typhon TLR

- Vorteks

- Thread starter

- #64

NO...please do not try to crack or force them. I know it has been said but that should not be necessary.So I’m getting this lockout of the diff often (or just way too stiff action that “pops” or jumps as opposed to the smoother chatter or click of the LSD effect) when I tighten the screws down final. If I loosen them just a little the diff feels fine and all is good, so I know there isn’t a damaged gear causing bad mesh or anything. It’s definitely just the compression of the system when screwed tight. I’d just go with loosening them but oil is leaking from the screws when I do (doesn’t take much loosening for oil to dribble out). I’m about to try this “cracking” method but obviously a little nervous as this doesn’t sound normal at all. Not to distrust you here spoc but anyone else confirm this is a safe and logical maneuver? Typically I’m against brute force methods just cause it shouldn’t be necessary.

I had the same issue when I put my LSD back. Please check it all over again to make sure all is assembled correctly and seated correctly. Sometimes I would not imagine in a new never ran setup that an outdrive shim needs to be removed (about 1.8 - 1.9mm of LSD plates, excluding the outdrive shims) or some form of shimming with stars, shims, or something.

#1 You need and should be able to tighten it all the way and it turn. Never leave it loose

#2 Yes, with LSD it will not have the nice fluid feel as you turn the outdrives like an open diff. It will have catchy, bump, gritty feel as you twist the outdrives, point they should turn

#3 LSD does like lighter fluid. However, even using heavy fluid I have 50wt in front and 500wt center in the center both are LSD. I can still turn my center outdrives with my hand NOTHING is LOCK. Stiff but turns.

You should have no locking so if you are tightening the 4 diff screws and it gets tight as you tighten...my experience shims are wrong or how it is put back together is wrong. Also, the diff gasket has and can get in the way make sure it is flat and not in the way of anything seating. I am not the smartest here but I do not like the idea of cracking or forcing them to turn by force if they are locked on assembled. I've never had or tried to do that but that is me.

jondilly1974

Speed running apprentice, motor Slayer 🤘

Lifetime Premium!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 26,134

- Reaction score

- 38,839

- Location

- Toledo, OH

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Kraton EXB

- Senton 3s

- Typhon 6s

- Typhon 3s

I have found that the star plates have a tendency to get misaligned ever so slightly when assembling the diff. I like to rock the output cup on the ring side a tiny bit as I put the ring gear on the cup. This helps seat the star plates into their grooves in the cup instead of getting stuck between the ring and cup.So I’m getting this lockout of the diff often (or just way too stiff action that “pops” or jumps as opposed to the smoother chatter or click of the LSD effect) when I tighten the screws down final. If I loosen them just a little the diff feels fine and all is good, so I know there isn’t a damaged gear causing bad mesh or anything. It’s definitely just the compression of the system when screwed tight. I’d just go with loosening them but oil is leaking from the screws when I do (doesn’t take much loosening for oil to dribble out). I’m about to try this “cracking” method but obviously a little nervous as this doesn’t sound normal at all. Not to distrust you here spoc but anyone else confirm this is a safe and logical maneuver? Typically I’m against brute force methods just cause it shouldn’t be necessary.

Spoc85

Active Member

- Messages

- 780

- Reaction score

- 876

- Location

- Australia

- Arrma RC's

- Infraction

- Limitless

- Kraton 6s

- Kraton EXB

- Outcast 6s

If you have the smooth side of the plates facing towards the sun gear and she locks up on you when you’ve torqued the diff down………crack it. If she feels notchy after that but you’re sure you have the diff setup right……..run a pack in and open area. Pull the diff after that run and I bet she spins smooth.So I’m getting this lockout of the diff often (or just way too stiff action that “pops” or jumps as opposed to the smoother chatter or click of the LSD effect) when I tighten the screws down final. If I loosen them just a little the diff feels fine and all is good, so I know there isn’t a damaged gear causing bad mesh or anything. It’s definitely just the compression of the system when screwed tight. I’d just go with loosening them but oil is leaking from the screws when I do (doesn’t take much loosening for oil to dribble out). I’m about to try this “cracking” method but obviously a little nervous as this doesn’t sound normal at all. Not to distrust you here spoc but anyone else confirm this is a safe and logical maneuver? Typically I’m against brute force methods just cause it shouldn’t be necessary.

Depending on how you’ve setup(min/max), you’ve just squashed a plate that’s suppose to spin between two other stationary plates. Initially there is going to be some resistance.

I know I shouldn’t but iv stabbed the throttle multiple times while the cars been cartwheeling along the ground to get her back on her feet. Still no issue.

She drove back to the car after this incident.

parcou

Premium Member!

Premium Member

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 6,223

- Reaction score

- 9,124

- Location

- Memphis, TN

- Arrma RC's

- BigRock

- Felony

- Fireteam

- Granite

- Infraction

- Kraton EXB

- Talion EXB

- Typhon TLR

- Vorteks

- Thread starter

- #67

@milehighspeed all good advice just posted here. Step back, take your time. I too been in this spot with this wisdom shared. Just pace yourself try one step at a time. LSD on my new Kraton setup in November was a crash course of learning, damn did I learn a lot with that, diff, shimming. But all thx to the Brothers here.

This may already be common knowledge, but just in case...

I bought some EXB diffs from Jenny's for my BLX Kraton. As mentioned on this forum before the front and rear diff p/n are the same. However, I disassembled mine tonight to double check they were setup correctly and to check the fluid.

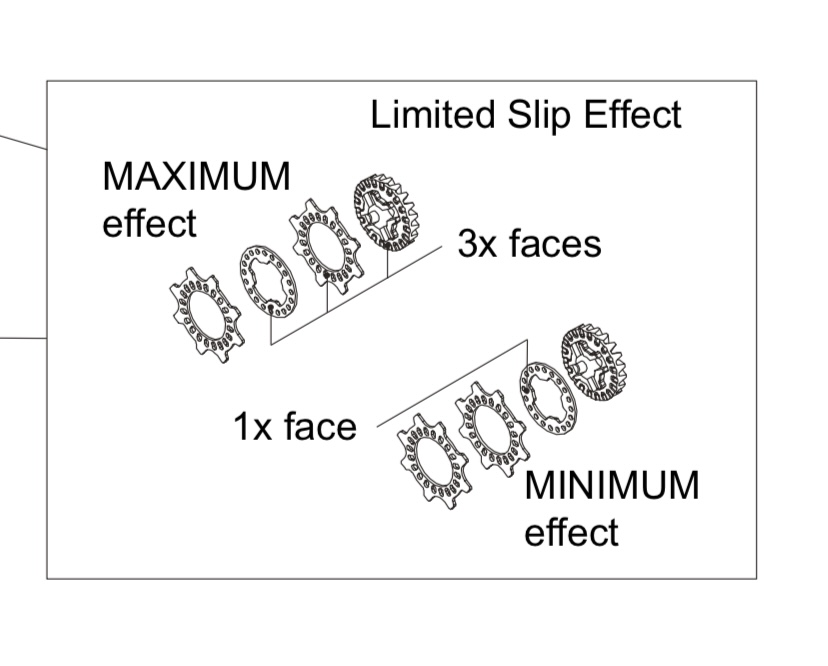

The diff marked "F" on the bag for front was set to "maximum effect" based on how the plates were stacked.

The diff marked "R" on the bag for rear was set to match the "minimum effect" based on how the plates were stacked.

Glad I opened them up, all three diffs had about half the amount of fluid in them that I think they're supposed to have. I've topped them up and everything's great except for one stripped diff screw that holds the two halves together. Came outta the diff housing like that so must have happened at ARRMA during assembly. I'm headed out to pick up a replacement now.

I bought some EXB diffs from Jenny's for my BLX Kraton. As mentioned on this forum before the front and rear diff p/n are the same. However, I disassembled mine tonight to double check they were setup correctly and to check the fluid.

The diff marked "F" on the bag for front was set to "maximum effect" based on how the plates were stacked.

The diff marked "R" on the bag for rear was set to match the "minimum effect" based on how the plates were stacked.

Glad I opened them up, all three diffs had about half the amount of fluid in them that I think they're supposed to have. I've topped them up and everything's great except for one stripped diff screw that holds the two halves together. Came outta the diff housing like that so must have happened at ARRMA during assembly. I'm headed out to pick up a replacement now.

Yep, properly marked with the right plate stacks. I am running very light fluid in the rear with a minimum stack, I am down to 3,000 in the rear and I like how it handles.This may already be common knowledge, but just in case...

I bought some EXB diffs from Jenny's for my BLX Kraton. As mentioned on this forum before the front and rear diff p/n are the same. However, I disassembled mine tonight to double check they were setup correctly and to check the fluid.

The diff marked "F" on the bag for front was set to "maximum effect" based on how the plates were stacked.

The diff marked "R" on the bag for rear was set to match the "minimum effect" based on how the plates were stacked.

View attachment 187104

Glad I opened them up, all three diffs had about half the amount of fluid in them that I think they're supposed to have. I've topped them up and everything's great except for one stripped diff screw that holds the two halves together. Came outta the diff housing like that so must have happened at ARRMA during assembly. I'm headed out to pick up a replacement now.

Yeah I wrote a small "R" on the rear diff with a silver sharpie so I'd keep them in the right spots going forward, unless I missed an actual mark from ARRMA LOL.

I picked up some diff fluid to do maintenance on my stock BLX diffs before I knew about the EXB ones being LSD and got some 30K to try up front. I come from the automotive hot rod world where LSD is king, so I thought it made sense for the RC.

My Kraton seems to want to turn very wide under even light throttle input and I wondered if it's from the weight transfer on the suspension and lifting the front tire on the outside causing power to go to it instead of even across the diff. I bought some 30K fluid to try in the stock BLX front diff, but maybe that's a waste of time now that I have the EXB ones? I was gonna experiment.

I picked up some diff fluid to do maintenance on my stock BLX diffs before I knew about the EXB ones being LSD and got some 30K to try up front. I come from the automotive hot rod world where LSD is king, so I thought it made sense for the RC.

My Kraton seems to want to turn very wide under even light throttle input and I wondered if it's from the weight transfer on the suspension and lifting the front tire on the outside causing power to go to it instead of even across the diff. I bought some 30K fluid to try in the stock BLX front diff, but maybe that's a waste of time now that I have the EXB ones? I was gonna experiment.

Roughly the max effect front and Center LSD diffs act like fluid 5x thicker and the minimum effect rear more like 3x. I run 3,000 in the rear and 30k up front should work. I suspect your rear is what is causing the handling problem. How does it handle of you turn with a bit of brake? I found the 10k fluid that was stock in the rear with a maximum effect stack far too thick. I tried 5k but now I’m at 3k. I may try lighter still.Yeah I wrote a small "R" on the rear diff with a silver sharpie so I'd keep them in the right spots going forward, unless I missed an actual mark from ARRMA LOL.

I picked up some diff fluid to do maintenance on my stock BLX diffs before I knew about the EXB ones being LSD and got some 30K to try up front. I come from the automotive hot rod world where LSD is king, so I thought it made sense for the RC.

My Kraton seems to want to turn very wide under even light throttle input and I wondered if it's from the weight transfer on the suspension and lifting the front tire on the outside causing power to go to it instead of even across the diff. I bought some 30K fluid to try in the stock BLX front diff, but maybe that's a waste of time now that I have the EXB ones? I was gonna experiment.

You can also try moving your shock positions. Have you checked camber? Have a look at camber gain too, are your rear tires gripping When you turn, particularly the outside tire?

@razorrc made a great video you should check out.

I'm new to these, so most of your questions I'm honestly not sure of. The truck seems to have grip on the rear turning under throttle. I'm still on the stock BLX diffs, haven't installed the EXB LSD ones yet. I'm also still on the stock BLX fluid of 10k/100k/10k. I just grabbed some 30K that I thought I'd try in the front when I picked up the 10K and 100K for servicing the BLX diffs as they're due.

My truck just flat doesn't wanna turn a tight radius under any throttle input. If I let off the throttle it turns just fine. I'll watch the video you posted to see what I can learn.

My truck just flat doesn't wanna turn a tight radius under any throttle input. If I let off the throttle it turns just fine. I'll watch the video you posted to see what I can learn.

- Messages

- 833

- Reaction score

- 939

- Location

- Central valley California

- Arrma RC's

- Kraton 6s

- Kraton EXB

- Typhon 3s

- Typhon 6s

- Voltage

For future reference anyone wanting a rear open diff can just buy it complete from Horizon Hobbies. ARA311066

Your welcome

Your welcome

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,877

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

I have gotten so many stripped plastic parts. Including many diff housings. I almost always ask HH to warranty them. I am tired of just buying something new twice, because new out the box, was poorly assembled. Just recently, the front brace at the Steering Top plate screw was stripped out the box. I ate this one and just bought a set of EXB F/R braces. My TLRT Typhon. SInce it was the only stripped part on this particular rig, I took one for the team. This time HH got a pass.This may already be common knowledge, but just in case...

I bought some EXB diffs from Jenny's for my BLX Kraton. As mentioned on this forum before the front and rear diff p/n are the same. However, I disassembled mine tonight to double check they were setup correctly and to check the fluid.

The diff marked "F" on the bag for front was set to "maximum effect" based on how the plates were stacked.

The diff marked "R" on the bag for rear was set to match the "minimum effect" based on how the plates were stacked.

View attachment 187104

Glad I opened them up, all three diffs had about half the amount of fluid in them that I think they're supposed to have. I've topped them up and everything's great except for one stripped diff screw that holds the two halves together. Came outta the diff housing like that so must have happened at ARRMA during assembly. I'm headed out to pick up a replacement now.

Yes, I can see where QC could be an issue here and there. Overall I've been pretty impressed considering how intricate some of this stuff is, but I'd want QC tighter if I were running the show at ARRMA.

On the open diff, is there a reason you wouldn't just get the cheap shim set rather than buying a complete diff, assuming you haven't broken one or something?

On the open diff, is there a reason you wouldn't just get the cheap shim set rather than buying a complete diff, assuming you haven't broken one or something?

- Messages

- 833

- Reaction score

- 939

- Location

- Central valley California

- Arrma RC's

- Kraton 6s

- Kraton EXB

- Typhon 3s

- Typhon 6s

- Voltage

Some may want a spare. Others may want both options without the need to swap plates everytime. And more importantly just the knowledge of that being not only available but the original design.

I got one free under warranty from Horizon hobbies. Had I not known that part #, because they were planning on sending the lsd rear.

I got one free under warranty from Horizon hobbies. Had I not known that part #, because they were planning on sending the lsd rear.

Seems very strange they changed the design mid stream as it were to something more complex. Happens though I guess. I come from the hot rod world where it's LSD or nothing in the 1:1 cars, so maybe I'm just bias. About to go out and finish up my diff swap and should have a better opinion this afternoon after running it, but admittedly I'm new to these vehicles so my opinion may not be worth much compared to more seasoned users.

The stock servo saver and bushed steering linkage are turds. Switching to the EXB (silver) servo saver spring and adding some shims (circlips or HR adjustable servo saver pillar) will improve things a lot, and the HR steering linkage frees things up even further.My truck just flat doesn't wanna turn a tight radius under any throttle input. If I let off the throttle it turns just fine. I'll watch the video you posted to see what I can learn.

milehighspeed

Active Member

Boy can i relate to poor builds lately. Ive had a few rants about My relatively new kraton exb factory build. Laundry list of issues as this one was truly assembled by someone with one eye out the door. They Cross threaded one of the red pilvot ball cap screws into the plastic hub. wedged the little rear hatchback access to the rear diff incorrectly and stripped one of those in doing so and also as a result seated the rear diff incorrectly. The real killer was the damn gallon of red locktite used on the wheel hex pin grub screws. Something that doesn’t even need any, and yet they spot welded the pin and the grub screw in there to where i snapped two allen wrenches and completely stripped two grub screws using quality drives trying to get them out. Even after spot heating them to break down the Loctite. I had to 3 stage drill out the grub screws to slowly disintegrate them but then still had to very carefully peen and hammer the pins free without Damaging the drive shaft. That kind of thing took me hours for something that should be 15 seconds to remove a screw. Drives you nuts. Sorry again for the rant…ill get over it someday….with therapyI have gotten so many stripped plastic parts. Including many diff housings. I almost always ask HH to warranty them. I am tired of just buying something new twice, because new out the box, was poorly assembled. Just recently, the front brace at the Steering Top plate screw was stripped out the box. I ate this one and just bought a set of EXB F/R braces. My TLRT Typhon. SInce it was the only stripped part on this particular rig, I took one for the team. This time HH got a pass.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,877

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

+1Boy can i relate to poor builds lately. Ive had a few rants about My relatively new kraton exb factory build. Laundry list of issues as this one was truly assembled by someone with one eye out the door. They Cross threaded one of the red pilvot ball cap screws into the plastic hub. wedged the little rear hatchback access to the rear diff incorrectly and stripped one of those in doing so and also as a result seated the rear diff incorrectly. The real killer was the damn gallon of red locktite used on the wheel hex pin grub screws. Something that doesn’t even need any, and yet they spot welded the pin and the grub screw in there to where i snapped two allen wrenches and completely stripped two grub screws using quality drives trying to get them out. Even after spot heating them to break down the Loctite. I had to 3 stage drill out the grub screws to slowly disintegrate them but then still had to very carefully peen and hammer the pins free without Damaging the drive shaft. That kind of thing took me hours for something that should be 15 seconds to remove a screw. Drives you nuts. Sorry again for the rant…ill get over it someday….with therapy

My worst nightmare was my Limitless. Everything you stated also was with my Lim. I couldn't even remove 3 of 4 wheels. Needed an impact gun to remove three wheels. They were junk. They were overtigtened so much that the wheels were binding. All Distorted wheel hexes. Crushed. The hubs were damaged. The pivot ball nuts cross threaded, o-rings falling out and damaged. A few Hub BB's damaged. Rear diff all locked up internally. Chassis was not stamped properly and all tweaked at the front end. . Over $300. needed in parts. I put a list together. The Lim Roller costs $400. I asked HH to replace the Lim. They said they were out of stock. It was newly released at the time. I waited over 2 months to find a Lim. Then I waited more than 2 months for HH to send me every part. I didn't run it for over 6 months since i got it.

The Hex pins on all the 6s Arrmas are always Red TL'ed. I always remove the pins out the box, and not wait till later. So I can warranty the axles and hubs and all related parts up front. HH know knows this pattern of poor QC at the factory. They get the same compliants of the same assy issues over and over. And they don't even question it. Just oblige the warranty most of the time. At least here in the States. Children and /or very Unskilled labor are assembling these without question, so HH will always warranty these out the box. HH has no control over QC at all. At least they have a 2 year warranty. If the QC was better, they would be even more popular than they are IMHO. Many have grown to dislike Arrma because of the poor QC alone. WIth some patience out the box Arrmas are very durable bashers at their pricepoint. Just be prepared for the Worst examples at times. My recent TLRT Typhon was probably the best built one to date. Out of 7 6s rigs in all. The TLRT just had 3 low filled diffs and one stripped part. Plastic braces were questionable also. Just Got EXB's instead. I count my blessings. I think I was just lucky with this one. QC has been poor for so many years. I think Arrma/HH feels it is just cheaper to warranty all the defects from poor assy in Cn. They will hope many will never notice the defects. And so many don't notice this out the box. Just that they are not really Ready To run 99% of the time. Needs to be rebuilt for the most part and all examined. Many just run them right away and then the rig just falls apart very early on. Frustration ensues. Especially newcomers to RC. Its too hard for HH to be there in Cn and oversee production runs. There is a big out of control disconnect between HH and the source. Probably even part of HH's business model in keeping the price point low.

Last edited: