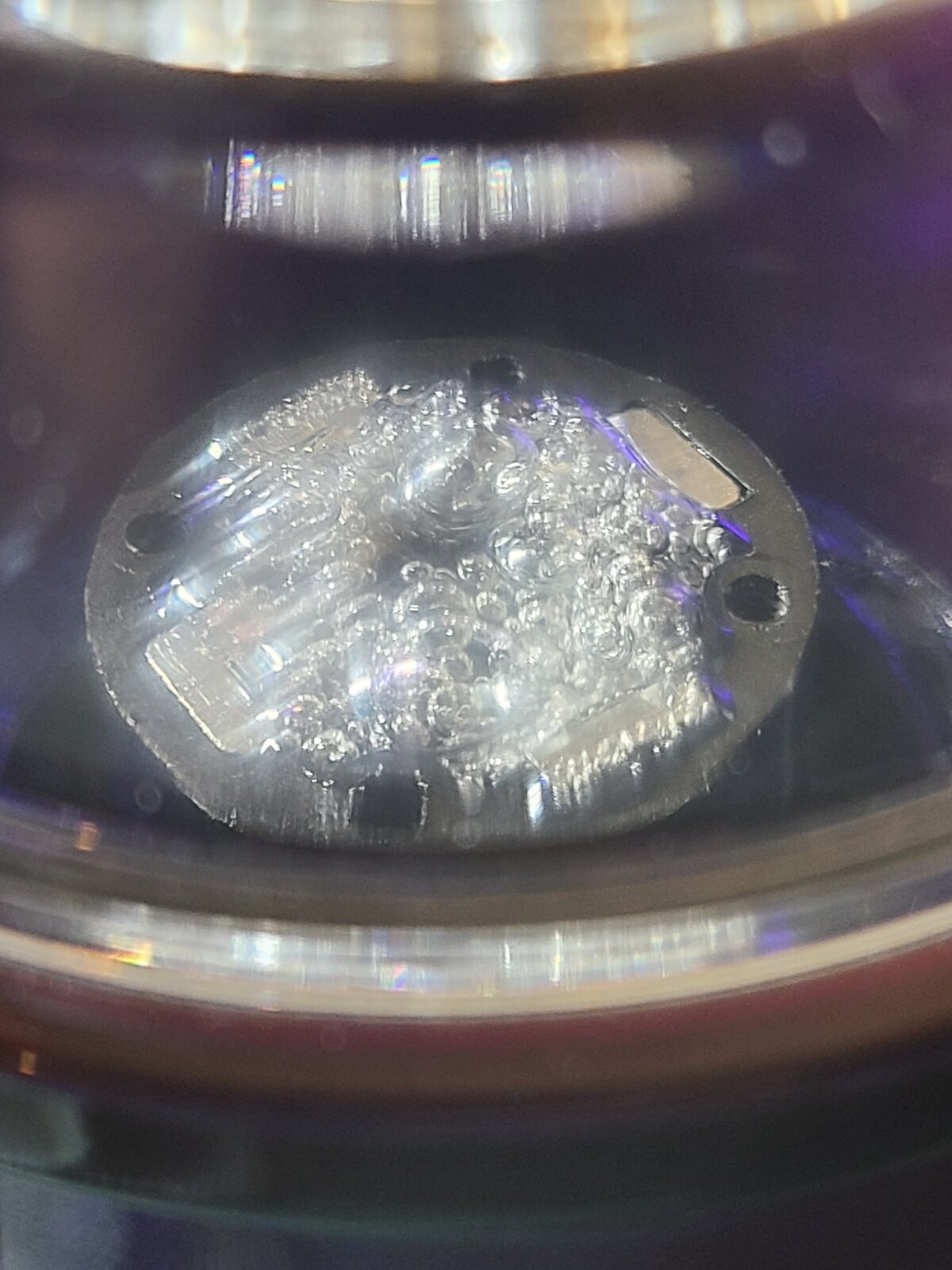

Being the newbie that I am, I figured I’d take a pic and ask here. I’m seeing what looks like a bunch of oil/grease on this part of the drive shaft going into the center diff as well as on this end of the chassis brace. This is on the Karton 6S V5. I’ve run it a total of three times with nothing heavy at all so I’m thinking it was like this out of the box. Any suggestions?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kraton 6S V5 - Is this a leaking center diff?

- Thread starter AristonC

- Start date

-

- Tags

- differential kraton

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

slick2500

Anything will break if you drive it wrong enough.

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 26,714

- Reaction score

- 42,011

- Location

- Rapid City, SD

- Arrma RC's

- Fireteam

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Senton 3s

- Typhon 3s

Most likely yes. I know when mine leaked it looked like this.

- Thread starter

- #3

Got it. Next question....is that just a matter of opening it up and seeing if I can find any broken parts? I should probably have some diff oil on hand if that’s the next step.

Take it apart. Can’t see enough to have any idea. Take it apart and look.

- Thread starter

- #5

Tools just arrived today so it looks like I have a Sunday project  Suppose this’ll be a fun first foray into how to all this stuff works.

Suppose this’ll be a fun first foray into how to all this stuff works.

Appreciate the help. Will post more once I get everything disassembled.

Appreciate the help. Will post more once I get everything disassembled.

Stock fluid is 100K. Might also want to have a new gasket on hand if that's somehow torn or not seated properly causing the leak.

jkflow

TB RC Bashers

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

Most likely a screw backed out and you will be able to see the leak. Fill it back up and tighten the screws, good to go.

- Thread starter

- #9

It’s dry on the other side of the diff, though. Would they put that oil only on one part of the car?That's just assembly oil they put on the car to prevent it from rusting. Diff ain't leaking .

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,869

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

They don't use assy oil. That's a leak.That's just assembly oil they put on the car to prevent it from rusting. Diff ain't leaking .

I have many 6s rigs here. Out the box, they even were leakers. Empty shocks, empty diffs dripping all over. F/R and Cntr.

They don't use assy oil. That's a leak.

I have many 6s rigs here. Out the box, they even were leakers. Empty shocks, empty diffs dripping all over. F/R and Cntr.

They haven’t been reliably filling the diffs anyway, so it’s worth opening them up and checking, filling properly with the fluid of your choice, ensuring a good gasket seal, and making sure the bleed screw is snug. The real danger of a leaking diff is that it runs dry and heats up until the bearings and diff case fail. Definitely pick up some extra gaskets in case the leak is due to a pinch or gap, or if you tear one taking it apart.

Extra bonus is you can check and add a shim where needed.

- Thread starter

- #12

Good info, thanks. Going to have to do trial and error since it’ll be first go at opening up a diff (YouTube ftw). I have some 100k oil and gaskets on order but may find another nearby hobby shop that may have them in stock.They haven’t been reliably filling the diffs anyway, so it’s worth opening them up and checking, filling properly with the fluid of your choice, ensuring a good gasket seal, and making sure the bleed screw is snug. The real danger of a leaking diff is that it runs dry and heats up until the bearings and diff case fail. Definitely pick up some extra gaskets in case the leak is due to a pinch or gap, or if you tear one taking it apart.

Extra bonus is you can check and add a shim where needed.

Good info, thanks. Going to have to do trial and error since it’ll be first go at opening up a diff (YouTube ftw). I have some 100k oil and gaskets on order but may find another nearby hobby shop that may have them in stock.

Not so long ago I had never removed or opened up a diff either. December for me. You’ll get the hang of it pretty quickly.

Two things I learned. 1. Never NEVER use a high speed power tool on any screws that go into plastic. That includes the wing mounts, diff covers, and the four that hold the diff together. I don’t just mean for starting or tightening them, don’t use a power tool at all. The high speed will quickly create heat from friction and melt the plastic a bit and you will end up stripping the screw hole. You may not notice at first, but you will seriously damage the plastic and weaken it. Only use good hand tools until you are experienced at doing this and you purchase a power driver that is slow enough not to heat up the screw and plastic and has an adjustable clutch. At that point the hand tools are about as fast anyway.

2. Video the disassembly process and organize your parts as you take it apart. Prop your phone up on something and start the video so you can refer back to it as needed. Lay out some shop towel or paper towel and lay out the parts in order. You can clean them one at a time and keep in order later. It’s much easier to keep them in order than to figure out which shim or washer goes where later on.

Lastly, invest in a set of MIP hex drivers. They are worth it. You will end up stripping screws and buying new hex drivers anyway that cost you more in the end.

- Thread starter

- #14

So this is what I ended up with. The bearings seem fine (I used to roller skate on fiber glass wheels so I’m familiar with bearings). Inside the diff it’s hard to tell how empty it is since as I turn the shaft the oil gushes up and down. Looking at the manual it doesn’t look like I should have any of the gaps that I see in the pics. Manual also doesn’t show any place where a gasket would go.

Also, should I shim or not shim since I have it open?

Thanks all for the help.

Also, should I shim or not shim since I have it open?

Thanks all for the help.

The gasket is stuck to the top of the diff cup it looks like. The fluid level should be roughly half way up the four spider gears let it sit for 15 minutes or so the way you are holding for the fluid to drain to the bottomSo this is what I ended up with. The bearings seem fine (I used to roller skate on fiber glass wheels so I’m familiar with bearings). Inside the diff it’s hard to tell how empty it is since as I turn the shaft the oil gushes up and down. Looking at the manual it doesn’t look like I should have any of the gaps that I see in the pics. Manual also doesn’t show any place where a gasket would go.

Also, should I shim or not shim since I have it open?

Thanks all for the help.

View attachment 129241

View attachment 129242

Looks like it has plenty of fluid. Possibly a bit too much. When you fill it and close it up don’t tighten the four screws down all the way at first. Turn it so that the bleed screw is facing up and let it sit for a half hour. Then loosen the bleed screw enough any air could escape. Tighten the four screws with the bleed screw loose and at the top. Once you snug those four screws you can tighten the bleed screw. I found I over filled the first few times I did it so I needed to bleed a bit of fluid as I tightened it up.

I suspect Arrma has been on top of the issue of diffs not being filled enough, so now some of the assemblers have used a bit too much fluid and they haven’t bled it properly so some leaked.

I suspect Arrma has been on top of the issue of diffs not being filled enough, so now some of the assemblers have used a bit too much fluid and they haven’t bled it properly so some leaked.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,869

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

Looks low to me. And I have my glasses on today.

I use a shock vacuum pump and make absolutely sure there is no air in the bottom. I will let real thick oil sit for several hours in the pump chamber. I end up adding a good amount more of oil afterwards. Much Air rises out of the oil. You cant rush filling diffs. Otherwise, you are underfilling them 99% of the time. The air that remains displaces the oil volume. And air that remains inside also creates more heat IMHO. The diff action will feel like you have thinner oil in there. I use that grub screw on the cup to allow any excess oil to pump out once I close it up. Usually just a bit comes and stops, then reinstall the setcrew. and there wont be any hydraulic locking within the diff this way. A few slow turns of the diff will expel excess oil if any. How I do it for years. I prefer to over fill than under fill. You get a more accurate and consistent diff action with your chosen oil.

I use a shock vacuum pump and make absolutely sure there is no air in the bottom. I will let real thick oil sit for several hours in the pump chamber. I end up adding a good amount more of oil afterwards. Much Air rises out of the oil. You cant rush filling diffs. Otherwise, you are underfilling them 99% of the time. The air that remains displaces the oil volume. And air that remains inside also creates more heat IMHO. The diff action will feel like you have thinner oil in there. I use that grub screw on the cup to allow any excess oil to pump out once I close it up. Usually just a bit comes and stops, then reinstall the setcrew. and there wont be any hydraulic locking within the diff this way. A few slow turns of the diff will expel excess oil if any. How I do it for years. I prefer to over fill than under fill. You get a more accurate and consistent diff action with your chosen oil.

Last edited:

- Thread starter

- #18

Cleaned it all up and put it back together. Will run it a bit later and see how it goes. Thanks everyone for the assistance!

Similar threads

- Replies

- 3

- Views

- 165