- Messages

- 1,628

- Reaction score

- 1,915

- Location

- Australia

- Arrma RC's

- BigRock 4x4

- Infraction

- Kraton 8S

- Kraton 6s

- Talion

- Typhon 6s

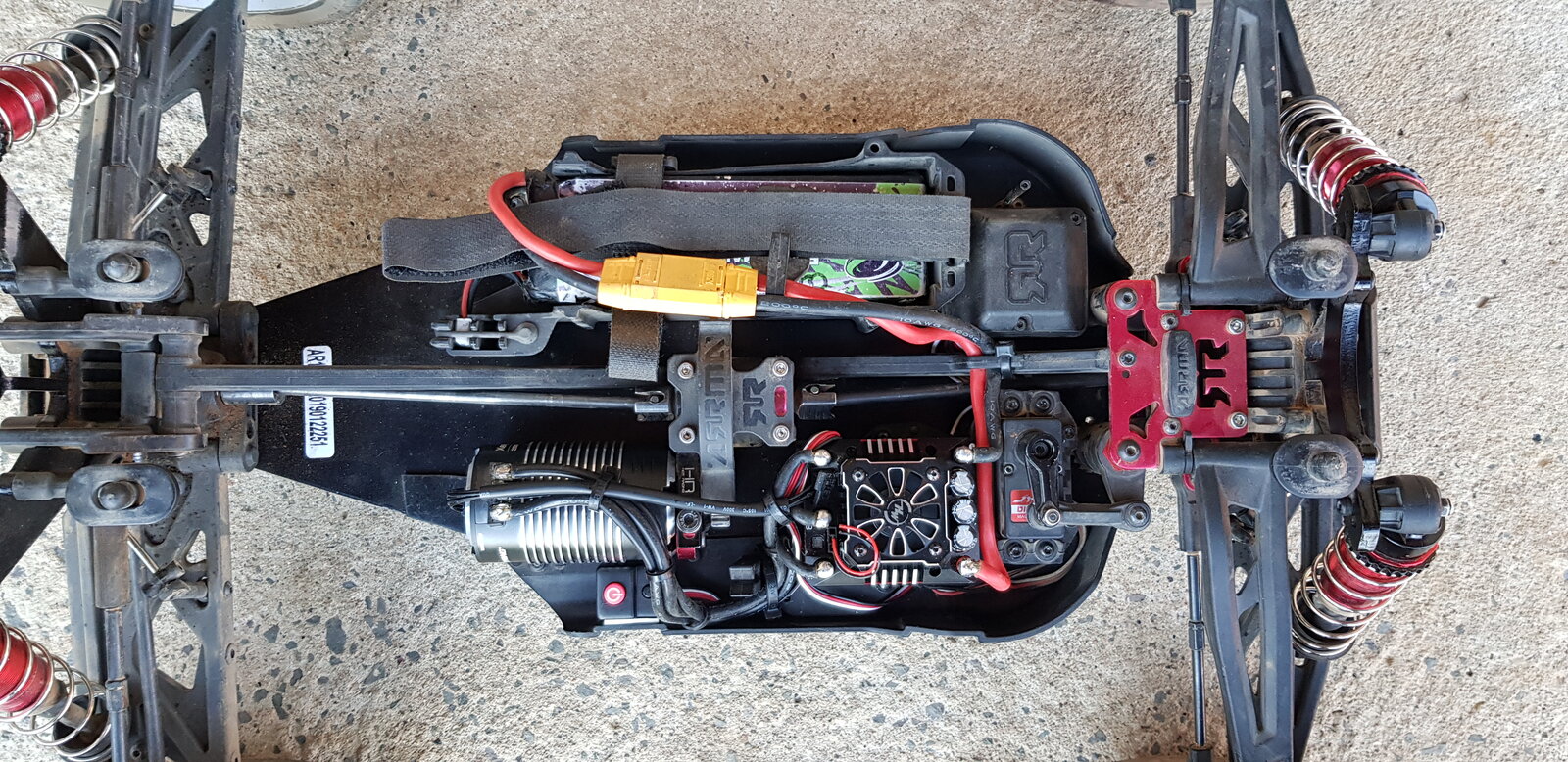

So continuing on from these posts:

https://www.arrmaforum.com/threads/race-spec-kraton-first-race-meet-and-test-drive-video.13942/

https://www.arrmaforum.com/threads/finally-finished-my-kraton-race-spec-build.13464/#post-163752

I thought I'd update you on my Kraton "Race Spec" build.

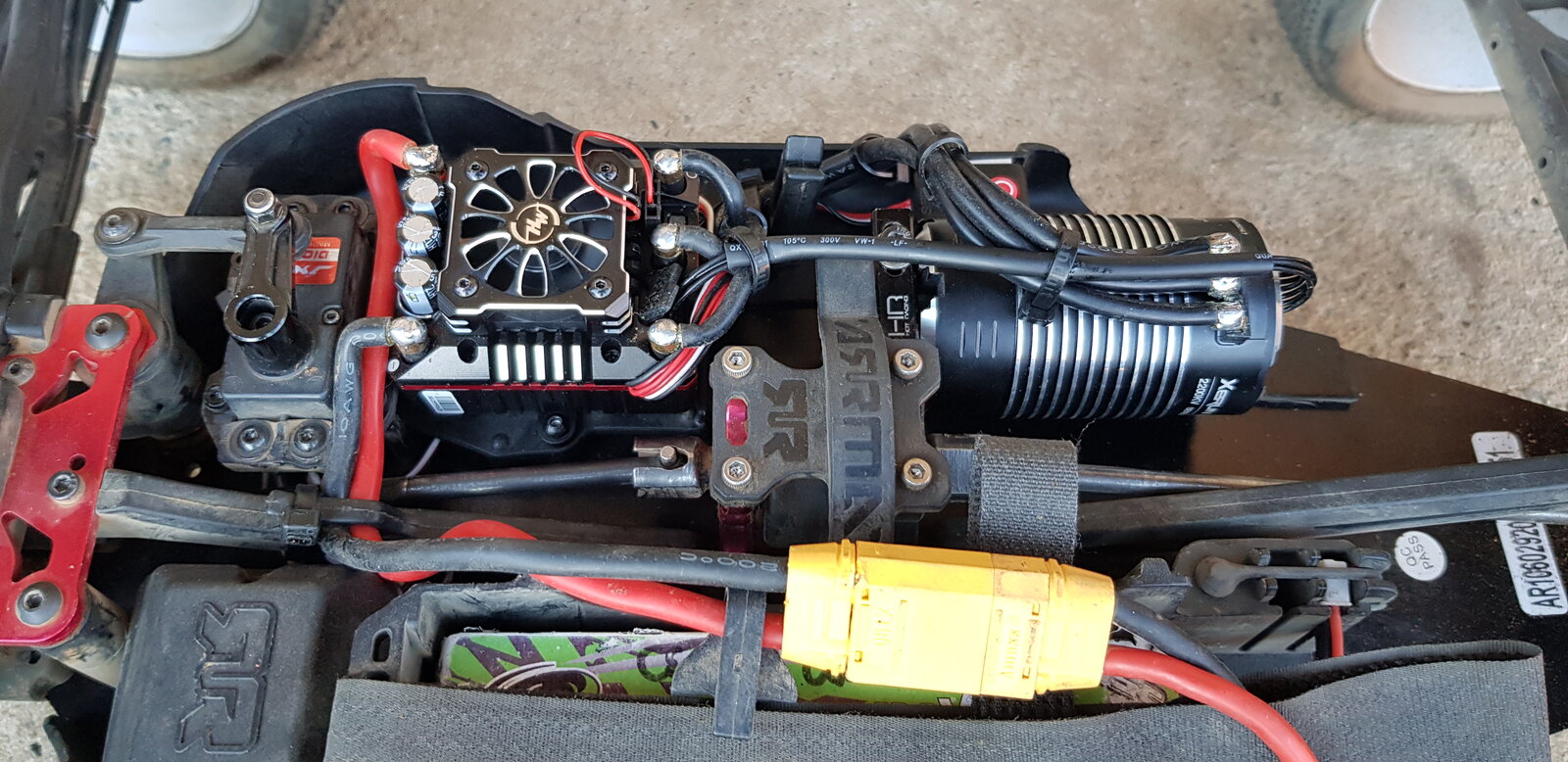

I am so happy with the result that I decided to make this budget build a little next level and what better way than to install a "Race Spec" motor and esc.

I went with the XeRun XR8 Plus and the 4268SD G2 2200kv initial testing is extremely promising. The reason for the smaller motor is I only run a very short track and don't think the longer can(4274SD) was needed, hopefully heat won't be an issue. I only run 4s on track also, I hope I can get a good setup with the right pinion, I've started with a 16t, but was wishing I had a 14t at hand. I'll have to buy a few different sizes, all my pinions are either way bigger or way smaller.

If anyone has any tips or suggestions please comment below.

https://www.arrmaforum.com/threads/race-spec-kraton-first-race-meet-and-test-drive-video.13942/

https://www.arrmaforum.com/threads/finally-finished-my-kraton-race-spec-build.13464/#post-163752

I thought I'd update you on my Kraton "Race Spec" build.

I am so happy with the result that I decided to make this budget build a little next level and what better way than to install a "Race Spec" motor and esc.

I went with the XeRun XR8 Plus and the 4268SD G2 2200kv initial testing is extremely promising. The reason for the smaller motor is I only run a very short track and don't think the longer can(4274SD) was needed, hopefully heat won't be an issue. I only run 4s on track also, I hope I can get a good setup with the right pinion, I've started with a 16t, but was wishing I had a 14t at hand. I'll have to buy a few different sizes, all my pinions are either way bigger or way smaller.

If anyone has any tips or suggestions please comment below.