Lufkin25

Member

- Messages

- 54

- Reaction score

- 30

- Arrma RC's

Just got started on rebuilding my kraton v3. I've had it for a few months now and have maybe 15 packs through it. I have learned a lot about these cars and made a lot of mistakes along the way. Hoping that some information or a picture I post will be able to help someone else with their build or with their arrma..

Here is my m2c chassis and skid plates. Ready to be assembled.

Here is what I have to start with. No body, a scratched and bent stock chassis and...

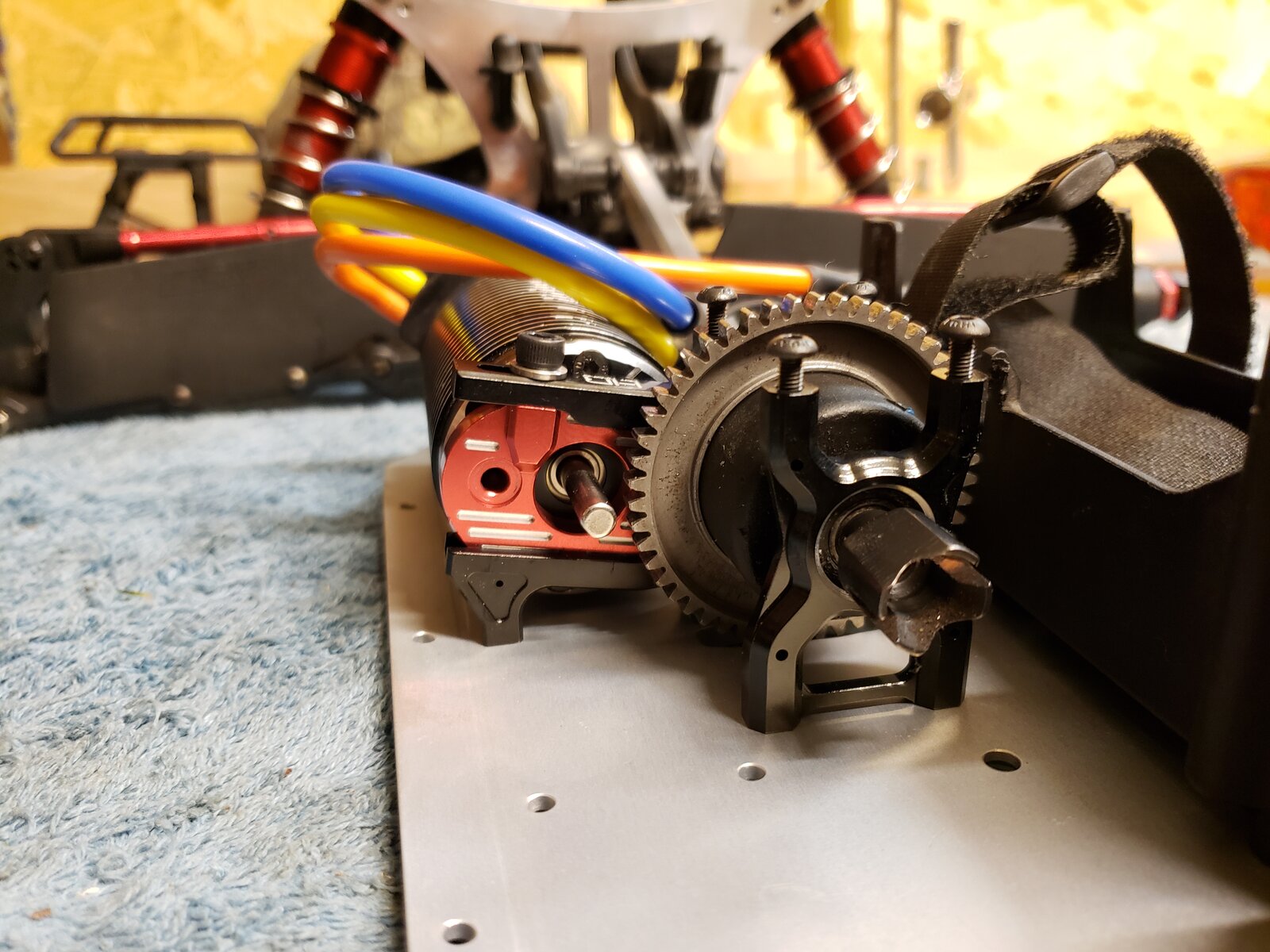

A stripped out motor gear with a stripped set and a missing motor mount screw.. remember I said I made some mistakes along they way? This was a few of them lol

I removed 4 x 4mm rear gear case screws and 1 x 4mm chassis brace screw to remove the entire rear end. I replaced the 5 screws after I fitted it to my new chassis. I used the 4 x 4mm long screws included with my m2c skid plate for use with the T Bone Racing 2.0 wheelie bar. Took a few tries to figure it out but I decided that the TBR wheelie bar goes on on top of the skid plate. So it goes chassis, skid plate, and then the wheelie bar.

Like this...

Then I installed my new hobbystar 4082 with a hot racing motor mount and center diff carrier. Waiting on some parts from voltage hobbies now... upper rear front suspension mount and steering rack. Both parts seem to bend on me a lot. I have had great luck with my voltage shock tower and rear chassis brace. They have taken a beating and are still true! I will post more when I make more progress. Hope this helps someone!

Here is my m2c chassis and skid plates. Ready to be assembled.

Here is what I have to start with. No body, a scratched and bent stock chassis and...

A stripped out motor gear with a stripped set and a missing motor mount screw.. remember I said I made some mistakes along they way? This was a few of them lol

I removed 4 x 4mm rear gear case screws and 1 x 4mm chassis brace screw to remove the entire rear end. I replaced the 5 screws after I fitted it to my new chassis. I used the 4 x 4mm long screws included with my m2c skid plate for use with the T Bone Racing 2.0 wheelie bar. Took a few tries to figure it out but I decided that the TBR wheelie bar goes on on top of the skid plate. So it goes chassis, skid plate, and then the wheelie bar.

Like this...

Then I installed my new hobbystar 4082 with a hot racing motor mount and center diff carrier. Waiting on some parts from voltage hobbies now... upper rear front suspension mount and steering rack. Both parts seem to bend on me a lot. I have had great luck with my voltage shock tower and rear chassis brace. They have taken a beating and are still true! I will post more when I make more progress. Hope this helps someone!