KevinC

Flyboy, Cat Hoarder, Tiger Tamer, Party Crasher.

Lifetime Premium!

Premium Member

Build Thread Contributor

- Messages

- 2,346

- Reaction score

- 4,034

- Location

- Brantford,Ontario

- Arrma RC's

- Fireteam

- Limitless

- Kraton 8S

- Kraton 6s

- Kraton EXB

- Mojave EXB

- Talion

- Talion EXB

Hey Arrma nation.

You guys running large motors (HW 56113, etc), .....are you using any support system under the motor at or near the front to mitigate shaft bending?

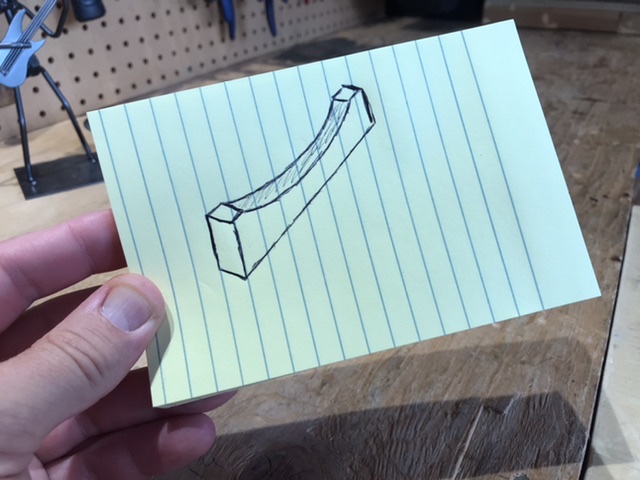

In my case I have the M2C chassis, mounter mount, and large pinion slider. My tiny physics minded brain tells me the weight of the 56113 creates quite a large moment arm past the joint axis that is the motor mount. Other than getting a custom 3D printed arched support like the drawing below, what are some other options? Should I even be concerned?

The M2C stuff is nice but the weak leak in the joint axis would now become the screws that mount from under the chassis and the sliding mount screws......just spitballing.......wanted to get a decent consensus and possible solutions.

cheers,

kev

You guys running large motors (HW 56113, etc), .....are you using any support system under the motor at or near the front to mitigate shaft bending?

In my case I have the M2C chassis, mounter mount, and large pinion slider. My tiny physics minded brain tells me the weight of the 56113 creates quite a large moment arm past the joint axis that is the motor mount. Other than getting a custom 3D printed arched support like the drawing below, what are some other options? Should I even be concerned?

The M2C stuff is nice but the weak leak in the joint axis would now become the screws that mount from under the chassis and the sliding mount screws......just spitballing.......wanted to get a decent consensus and possible solutions.

cheers,

kev