- Messages

- 10,063

- Reaction score

- 24,711

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

I figured I would start a dedicated thread for this build and share with my Arrma family/friends here because we have the best forum in the world.

For those less informed about RC boats there are about 4 different hull types. Each as it's strengths you can read more about that in the general RC boating thread .

Per my usual I wanted to build something custom from composites, CAD design, and way too fast (if there is such a thing.)

Out riggers some times called just riggers, shrimp boats, or classified as Hydros and they are the fastest design by far.

The current world record is held by the JAGs team at 206 mph. Video of that boat record run here.

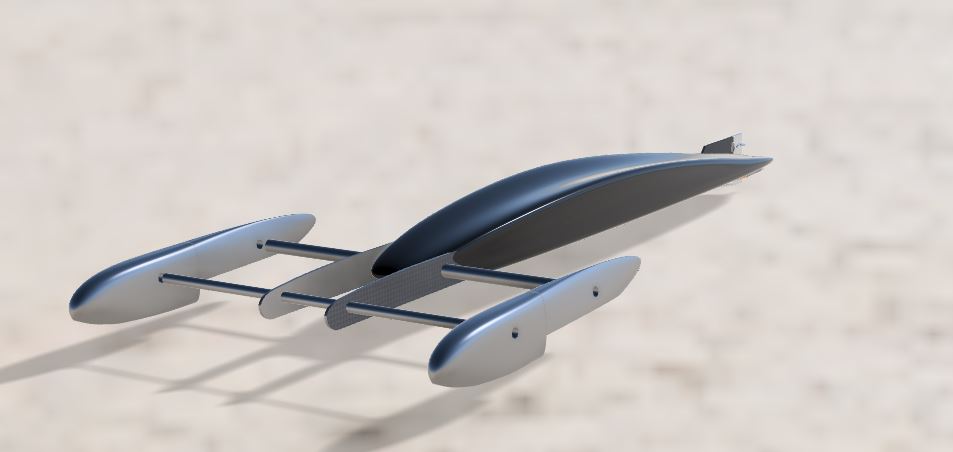

The idea is absolute minimal drag in both the water and the air. The boat is actually flying just above the water using ground effect airplane principles. You can see the design nearly replicates the shape of an airplane.

At any rate I have some amazing ponds close to home versus having no great roads over 1000ft for RC car speed runs, so I started dabbling in boats! (I will still finish my 200+ mph car build this winter)

I am on my 5th version of the design and it looks something like this:

Over the past weekend I began printing the front parts which are called sponsons in two parts. They are 400mm long.

The entire boat is 48" long for some perspective on how big it will be.

In this picture they are both on an aluminum rod I found in the garage. In final form I will be using carbon fiber tubes...

The sponsons will "skinned" in fiberglass to simplify the process versus making molds and making the parts from carbon fiber.

I expect I will revise the design after testing and learning, so there is no point in making the final molds and final draft version just yet.

Should be a fun/interesting process. Starting out I will be working my way up to a goal of 130+MPH. Depending on how that goes I might shoot for the moon

Currently my Creality CR-10 S Pro is printing 1/3 of the main center hull. That 1/3 of the hull is a 40 hour print (3D printers are a life saver and time saver in this world of home made custom designs!!!)

Stay tuned for more!

For those less informed about RC boats there are about 4 different hull types. Each as it's strengths you can read more about that in the general RC boating thread .

Per my usual I wanted to build something custom from composites, CAD design, and way too fast (if there is such a thing.)

Out riggers some times called just riggers, shrimp boats, or classified as Hydros and they are the fastest design by far.

The current world record is held by the JAGs team at 206 mph. Video of that boat record run here.

The idea is absolute minimal drag in both the water and the air. The boat is actually flying just above the water using ground effect airplane principles. You can see the design nearly replicates the shape of an airplane.

At any rate I have some amazing ponds close to home versus having no great roads over 1000ft for RC car speed runs, so I started dabbling in boats! (I will still finish my 200+ mph car build this winter)

I am on my 5th version of the design and it looks something like this:

Over the past weekend I began printing the front parts which are called sponsons in two parts. They are 400mm long.

The entire boat is 48" long for some perspective on how big it will be.

In this picture they are both on an aluminum rod I found in the garage. In final form I will be using carbon fiber tubes...

The sponsons will "skinned" in fiberglass to simplify the process versus making molds and making the parts from carbon fiber.

I expect I will revise the design after testing and learning, so there is no point in making the final molds and final draft version just yet.

Should be a fun/interesting process. Starting out I will be working my way up to a goal of 130+MPH. Depending on how that goes I might shoot for the moon

Currently my Creality CR-10 S Pro is printing 1/3 of the main center hull. That 1/3 of the hull is a 40 hour print (3D printers are a life saver and time saver in this world of home made custom designs!!!)

Stay tuned for more!

Last edited: