- Messages

- 10,087

- Reaction score

- 24,794

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

It is pretty clear that the Ford FC100 body is really good for speed runs.

We now have several guys guys in the 189 to 204 mph speeds with this body running a Limitless/Infraction. I suspect we will see Raz crack that 200 mph barrier very soon. (perks of having access to an airport runway)

While this body is good in plastic form it could be better if you didn't have the strength/flex issues that plastic has requiring many extra body contours that are not necessary.

In prior vacuum forming projects I learned that plastic requires some hard lines and extra bends to keep its rigidity. Composites like fiberglass and carbon fiber do not have those same issues, but can also benefit from them. Finding a balance is key.

Goal number #1 is to not go crazy. This body is good as is. I only want to make some minor tweaks to improve the airflow and reduce turbulence.

Making a plaster copy of the body is what I have found is best.

Here is the process for this project:

1. Paint the body, no cutting etc. Must leave the protective film on the outside of the body.

2. Mark the borders of the body onto a large stiff board. I used 3/4" mdf

3. Cut a hole smaller than the body and then glue the body to that board with liquid nails. Make sure the majority is going on top of the film on the body.

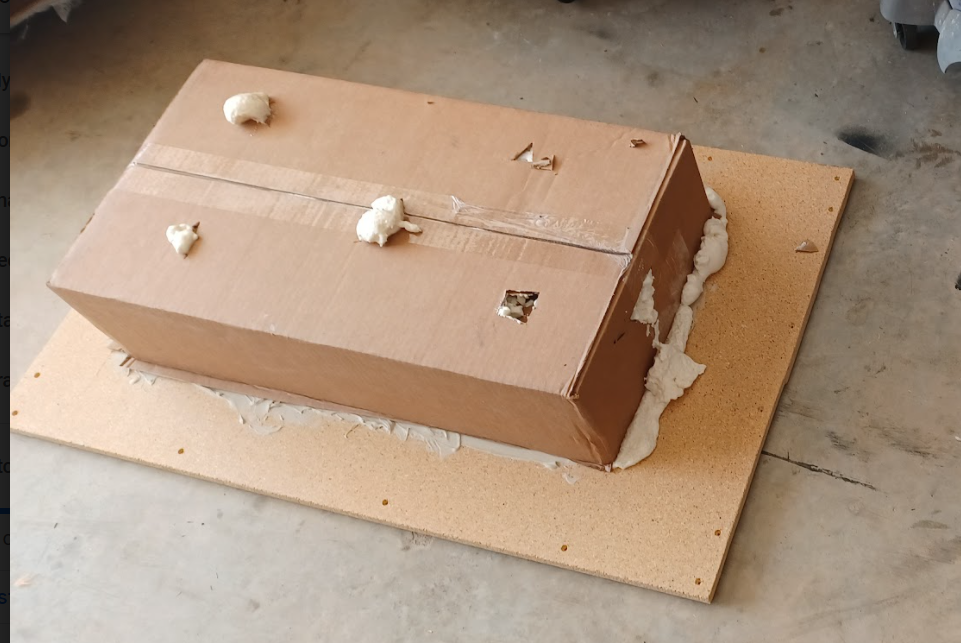

4. Put the box that this body came with over the body and wood. Then cut some holes in the box and fill the cavity with expanding foam. The foam will lock the body to the board. (the foam keeps the plastic body from flexing under the heavy weight of the plaster.)

5. Flip the entire thing over and wax the inside of the body heavily.

6. Fill the body with plaster in 3+ layers with 1-2 days dry time between.

To my surprise the foam removed from the body quite easily in large chunks:

The plaster body revealed and the film still on the original plastic body.

FYI this took 48 lbs of plaster!!!!!!!!

Plastic film removed from the original body. Tried for a mirror finish but only turned out at a dull chrome. I think I didn't have the body warm enough as I found light layers and heat helped the Spazstix mirror paint turn out better. Overall I think it still looks nice...

This week I'll begin making some small changes/improvements to the plaster copy.

I really love this sort of thing as it feels like art/sculpture work

We now have several guys guys in the 189 to 204 mph speeds with this body running a Limitless/Infraction. I suspect we will see Raz crack that 200 mph barrier very soon. (perks of having access to an airport runway)

While this body is good in plastic form it could be better if you didn't have the strength/flex issues that plastic has requiring many extra body contours that are not necessary.

In prior vacuum forming projects I learned that plastic requires some hard lines and extra bends to keep its rigidity. Composites like fiberglass and carbon fiber do not have those same issues, but can also benefit from them. Finding a balance is key.

Goal number #1 is to not go crazy. This body is good as is. I only want to make some minor tweaks to improve the airflow and reduce turbulence.

Making a plaster copy of the body is what I have found is best.

Here is the process for this project:

1. Paint the body, no cutting etc. Must leave the protective film on the outside of the body.

2. Mark the borders of the body onto a large stiff board. I used 3/4" mdf

3. Cut a hole smaller than the body and then glue the body to that board with liquid nails. Make sure the majority is going on top of the film on the body.

4. Put the box that this body came with over the body and wood. Then cut some holes in the box and fill the cavity with expanding foam. The foam will lock the body to the board. (the foam keeps the plastic body from flexing under the heavy weight of the plaster.)

5. Flip the entire thing over and wax the inside of the body heavily.

6. Fill the body with plaster in 3+ layers with 1-2 days dry time between.

To my surprise the foam removed from the body quite easily in large chunks:

The plaster body revealed and the film still on the original plastic body.

FYI this took 48 lbs of plaster!!!!!!!!

Plastic film removed from the original body. Tried for a mirror finish but only turned out at a dull chrome. I think I didn't have the body warm enough as I found light layers and heat helped the Spazstix mirror paint turn out better. Overall I think it still looks nice...

This week I'll begin making some small changes/improvements to the plaster copy.

I really love this sort of thing as it feels like art/sculpture work

Last edited: