RCklir

Member

- Messages

- 33

- Reaction score

- 21

- Arrma RC's

- Talion

I have found the problem and contacted hw so maybe they will fix it.

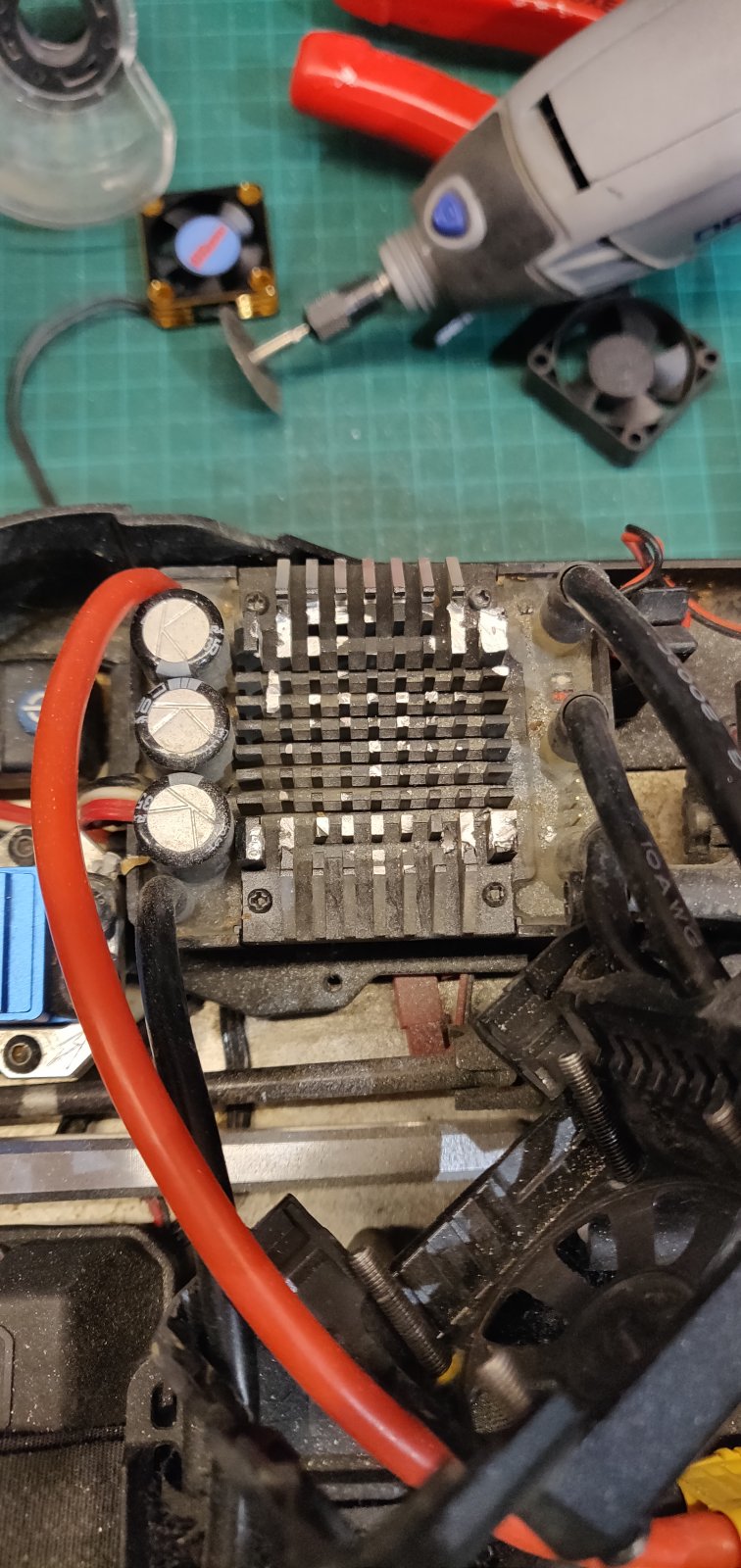

The problem is that the heatsink in the esc is badly designed it causes the fan to break easily.

the four corners of the fan is elevated from the center so most of the fan is "in the air" and not supported , each time you jump the car all the force goes to the center of the fan and breaks it.

what i did to fix it is Dremel it down.

The problem is that the heatsink in the esc is badly designed it causes the fan to break easily.

the four corners of the fan is elevated from the center so most of the fan is "in the air" and not supported , each time you jump the car all the force goes to the center of the fan and breaks it.

what i did to fix it is Dremel it down.