- Messages

- 223

- Reaction score

- 476

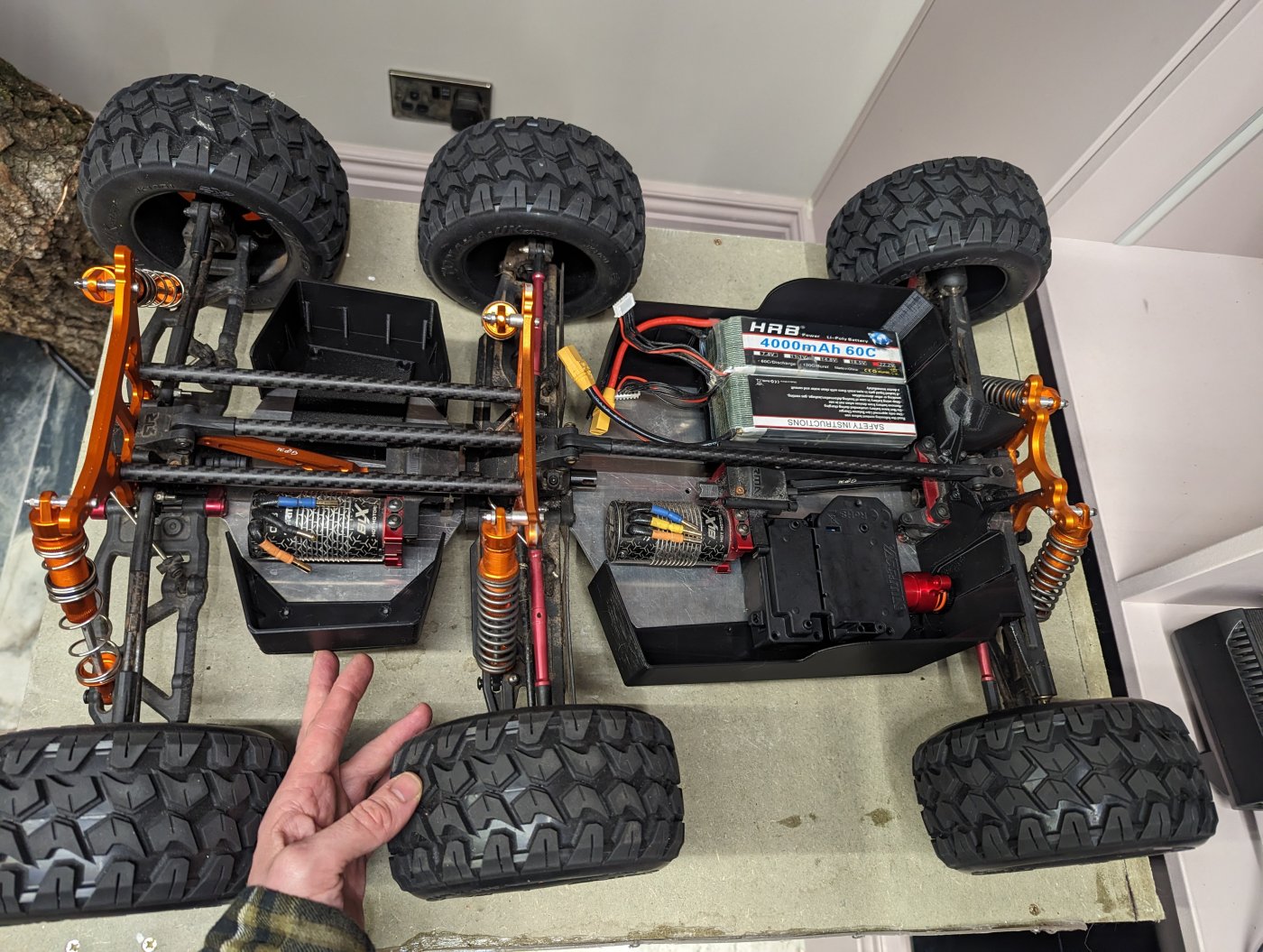

- Arrma RC's

- Kraton 6s

- Outcast 6s

So i love my new printer the ender 3 s1 pro, and have been printing non stop since getting it.

I've designed and prototyped a load of parts in PLA, but it is nowhere near durable or flexible or strong enough for 90% of my parts on an RC car.

So i have a few questions, what is the best suited filament for the parts im printing that can be printed on my printer with no mods, im guessing a TPU or a Nylon, but i don't know enough (and there seems to be a million different TPU and Nylons) and was hoping some of you more experienced people, who have been there and tried these things can help.

Secondly is there a better filament that could be used with just a few mods to my printer?

I've attached a picture of the parts so you can advise better on suitable filaments.

I've designed and prototyped a load of parts in PLA, but it is nowhere near durable or flexible or strong enough for 90% of my parts on an RC car.

So i have a few questions, what is the best suited filament for the parts im printing that can be printed on my printer with no mods, im guessing a TPU or a Nylon, but i don't know enough (and there seems to be a million different TPU and Nylons) and was hoping some of you more experienced people, who have been there and tried these things can help.

Secondly is there a better filament that could be used with just a few mods to my printer?

I've attached a picture of the parts so you can advise better on suitable filaments.