SaltyLocal

Active Member

- Messages

- 331

- Reaction score

- 176

Teared down my K6s V5 this evening and decided I better start a build thread before I get to far along. Nothing crazy or over the top, but being this is my first hobby grade RC, I feel I’m slowly getting it (kudos to all you helpful members).

Mid summer of this year, I purchased my son a Big Rock v3 for his 6th Birthday. Since I couldn’t leave him to bash alone , I figured it’d only be fair to purchase a big dad toy! After about 10 packs through and adding several “durability” parts to the exterior (listed below), I decided to start adding some under-the-hood upgrades.

, I figured it’d only be fair to purchase a big dad toy! After about 10 packs through and adding several “durability” parts to the exterior (listed below), I decided to start adding some under-the-hood upgrades.

Exterior additions:

- T-Bone Racing wheelie bar and rear skid plate

- RPM front bumper

- RPM wing mount

- Outcast 6s taller side skirts

- 3D printed roof and hood guards

- Two coats of Clear Rubber Flex sealant on inner body

Interior/Suspension:

- stock Spektrum motor, receiver and ESC

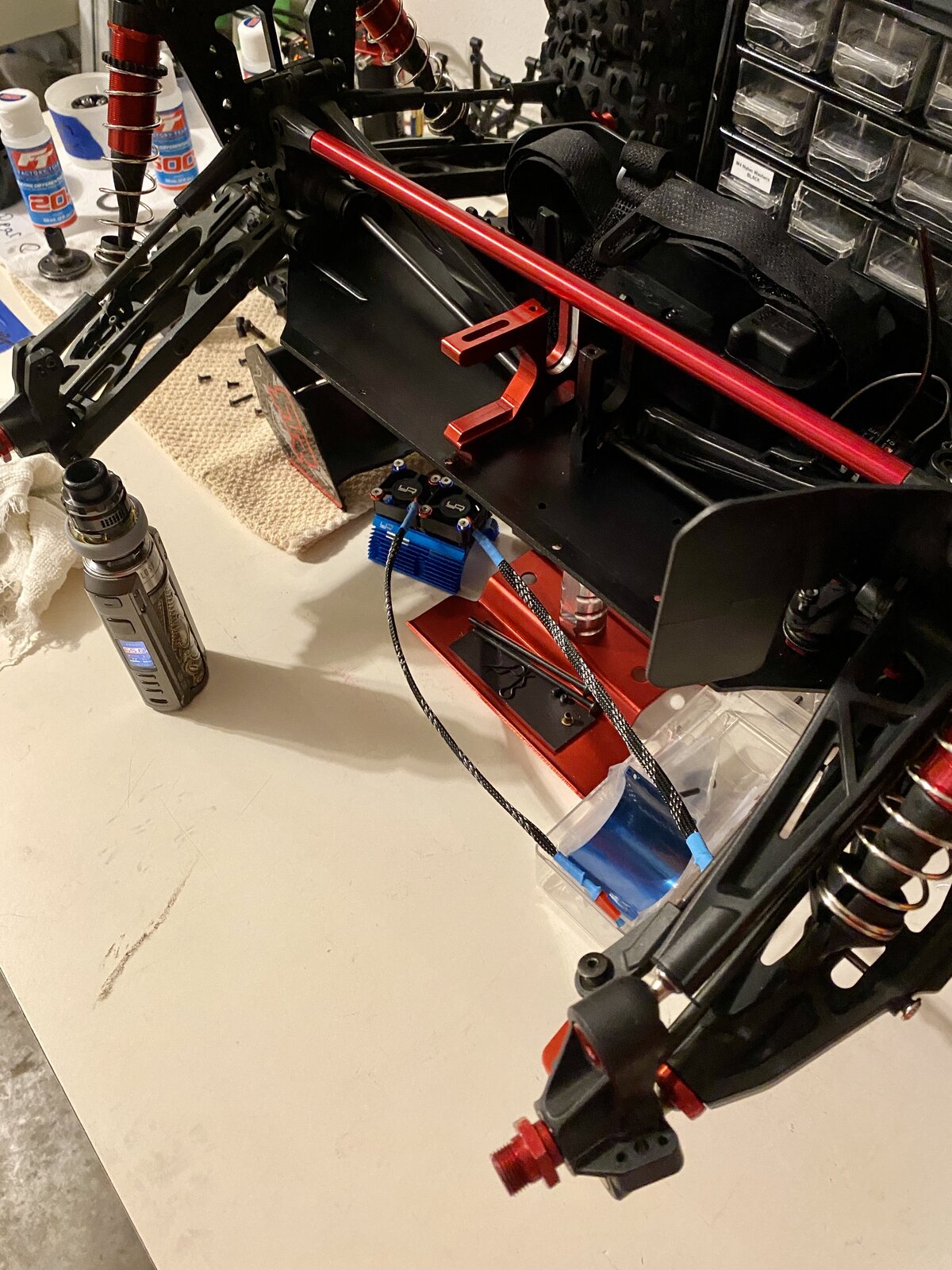

- Yeah Racing blue heatsink and dual 30mm fans (black/silver braid wire shields and heat-shrink added)

- Saxon SB2273 (estimated 388kg)

- Hot Racing aluminum servo mount

- Hot Racing bellcrank linkage with bearings

- Hot Racing 25t servo arm

- Hot Racing servo saver tube with clamping nut

- Team Associated diff fluid, F=60k, C=500k, R=20k

Started tear down this past weekend and let the diffs drain their stock fluid over night. Added the above TA fluids this evening and I’ll check levels (not sure exactly where to top them off at if anyone can suggest) after work tomorrow.

Here are a few pics from this evening.

Do these fluid levels look ok?

Does it matter which side the diff gasket is attached to prior to screwing back together?

Rear outside shim was bent like this when I removed it. How’d that happen?? Maybe it occurred during extraction from its’ case?

Steering project for later this week. To be continued…

Tools:

MIPs hex drivers

Dynamite socket drivers

Loctite (blue)

White grease (@WoodiE too thread recommendation)

- Craftsman 6 gallon air compressor and attachments (had to after going through 5+ cans of canned air)

- 3D printed tool stands for storage

*** To this day, I’m really not sure why my Wife is constantly complaining that we’re in so much debt. #Facts

Yet, another question; when I removed all three diffs from their cups, they were caked with thick grease. Is there a proper way of adding grease back into the cups, since I wiped off all the grease from the outside of the diffs themselves? Do I just use the white grease that was recommended in @WoodiE tool thread?

* edited typos

Mid summer of this year, I purchased my son a Big Rock v3 for his 6th Birthday. Since I couldn’t leave him to bash alone

Exterior additions:

- T-Bone Racing wheelie bar and rear skid plate

- RPM front bumper

- RPM wing mount

- Outcast 6s taller side skirts

- 3D printed roof and hood guards

- Two coats of Clear Rubber Flex sealant on inner body

Interior/Suspension:

- stock Spektrum motor, receiver and ESC

- Yeah Racing blue heatsink and dual 30mm fans (black/silver braid wire shields and heat-shrink added)

- Saxon SB2273 (estimated 388kg)

- Hot Racing aluminum servo mount

- Hot Racing bellcrank linkage with bearings

- Hot Racing 25t servo arm

- Hot Racing servo saver tube with clamping nut

- Team Associated diff fluid, F=60k, C=500k, R=20k

Started tear down this past weekend and let the diffs drain their stock fluid over night. Added the above TA fluids this evening and I’ll check levels (not sure exactly where to top them off at if anyone can suggest) after work tomorrow.

Here are a few pics from this evening.

Do these fluid levels look ok?

Does it matter which side the diff gasket is attached to prior to screwing back together?

Rear outside shim was bent like this when I removed it. How’d that happen?? Maybe it occurred during extraction from its’ case?

Steering project for later this week. To be continued…

Tools:

MIPs hex drivers

Dynamite socket drivers

Loctite (blue)

White grease (@WoodiE too thread recommendation)

- Craftsman 6 gallon air compressor and attachments (had to after going through 5+ cans of canned air)

- 3D printed tool stands for storage

*** To this day, I’m really not sure why my Wife is constantly complaining that we’re in so much debt. #Facts

Yet, another question; when I removed all three diffs from their cups, they were caked with thick grease. Is there a proper way of adding grease back into the cups, since I wiped off all the grease from the outside of the diffs themselves? Do I just use the white grease that was recommended in @WoodiE tool thread?

* edited typos

Last edited: