TwiZted SkullZ

Active Member

Do to some bad crashes/landings etc. plastic stuff breaks,it's inevitable!

And Arrma just doesn't seem to keep up with supply and demand for extra parts....

B/O is a pretty common thing with the Arrma website when trying to order a broken part!

Btw,I first tried some JB Weld but it just didn't adhere to this particular kind of hardened plastic.

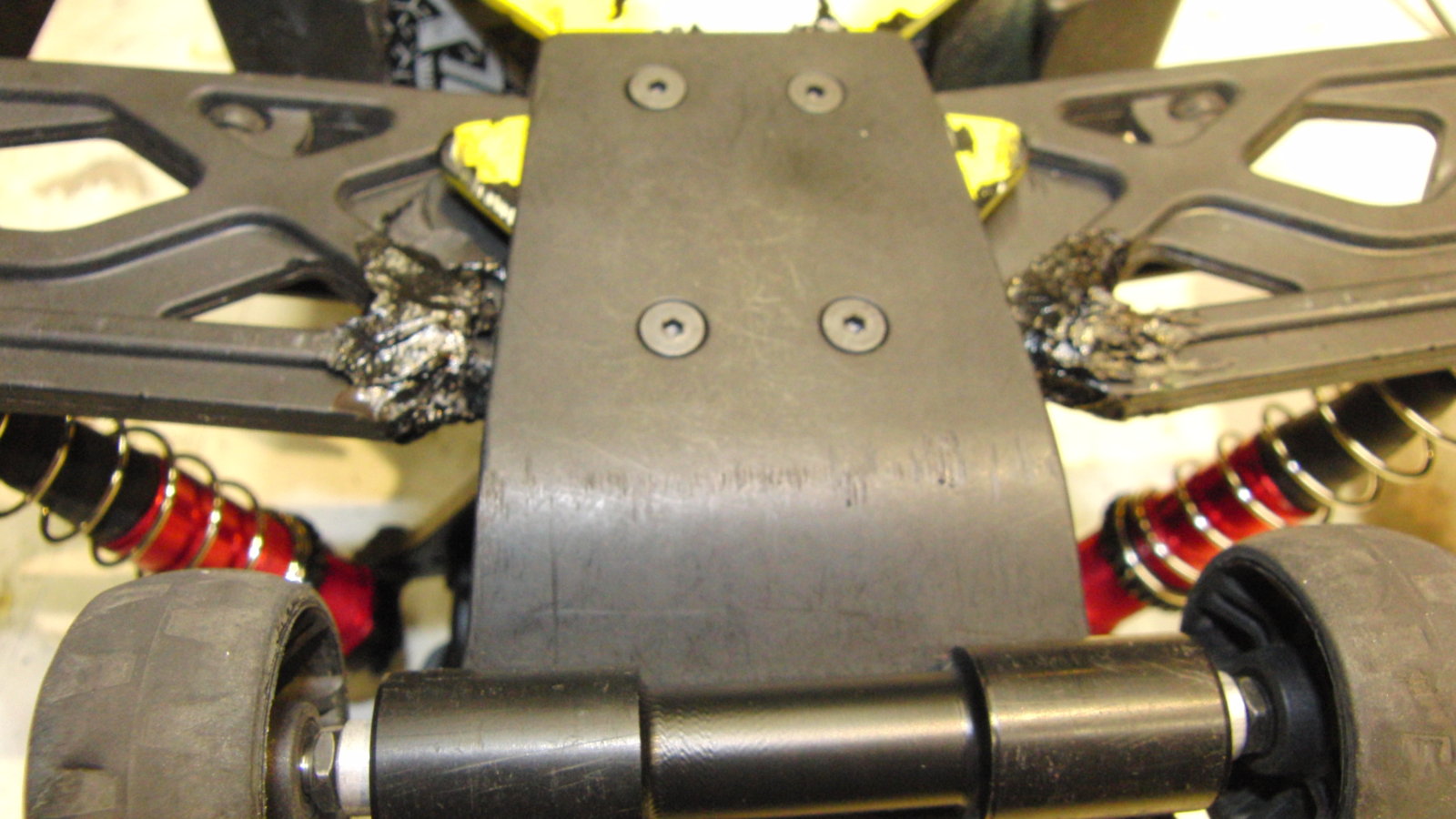

So here's a way I tried to repair a cracked lower A-arm joint on my Outcast.

It's basically a crude form of plastic welding,"spin welding" would be the best way to go but I don't have one those cool little tools.

Anyway,you just need a good soldering iron that gets hot enough to melt the plastic and some similar type scrap plastic to act like a welding rod to help build up and strengthen the surrounding area.

Then simply heat the cracked area and try to melt the broken/cracked part back together without distorting it too much.

At the same time feed some of the scrap plastic into the part you're heating and slowly build up the broken part so it all becomes one piece.

Add the scrap plastic as you go

Doesn't look pretty,but should get me by till a replacement comes in.

WARNING: Do this with adjudicate ventilation or wear a respirator as the smoke/fumes from melting plastic don't smell very good!

I just hope this works now,should be doing some testing/bashing this weekend!

And Arrma just doesn't seem to keep up with supply and demand for extra parts....

B/O is a pretty common thing with the Arrma website when trying to order a broken part!

Btw,I first tried some JB Weld but it just didn't adhere to this particular kind of hardened plastic.

So here's a way I tried to repair a cracked lower A-arm joint on my Outcast.

It's basically a crude form of plastic welding,"spin welding" would be the best way to go but I don't have one those cool little tools.

Anyway,you just need a good soldering iron that gets hot enough to melt the plastic and some similar type scrap plastic to act like a welding rod to help build up and strengthen the surrounding area.

Then simply heat the cracked area and try to melt the broken/cracked part back together without distorting it too much.

At the same time feed some of the scrap plastic into the part you're heating and slowly build up the broken part so it all becomes one piece.

Add the scrap plastic as you go

Doesn't look pretty,but should get me by till a replacement comes in.

WARNING: Do this with adjudicate ventilation or wear a respirator as the smoke/fumes from melting plastic don't smell very good!

I just hope this works now,should be doing some testing/bashing this weekend!