jondilly1974

Speed running apprentice, motor Slayer 🤘

Lifetime Premium!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 26,134

- Reaction score

- 38,838

- Location

- Toledo, OH

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Kraton EXB

- Senton 3s

- Typhon 6s

- Typhon 3s

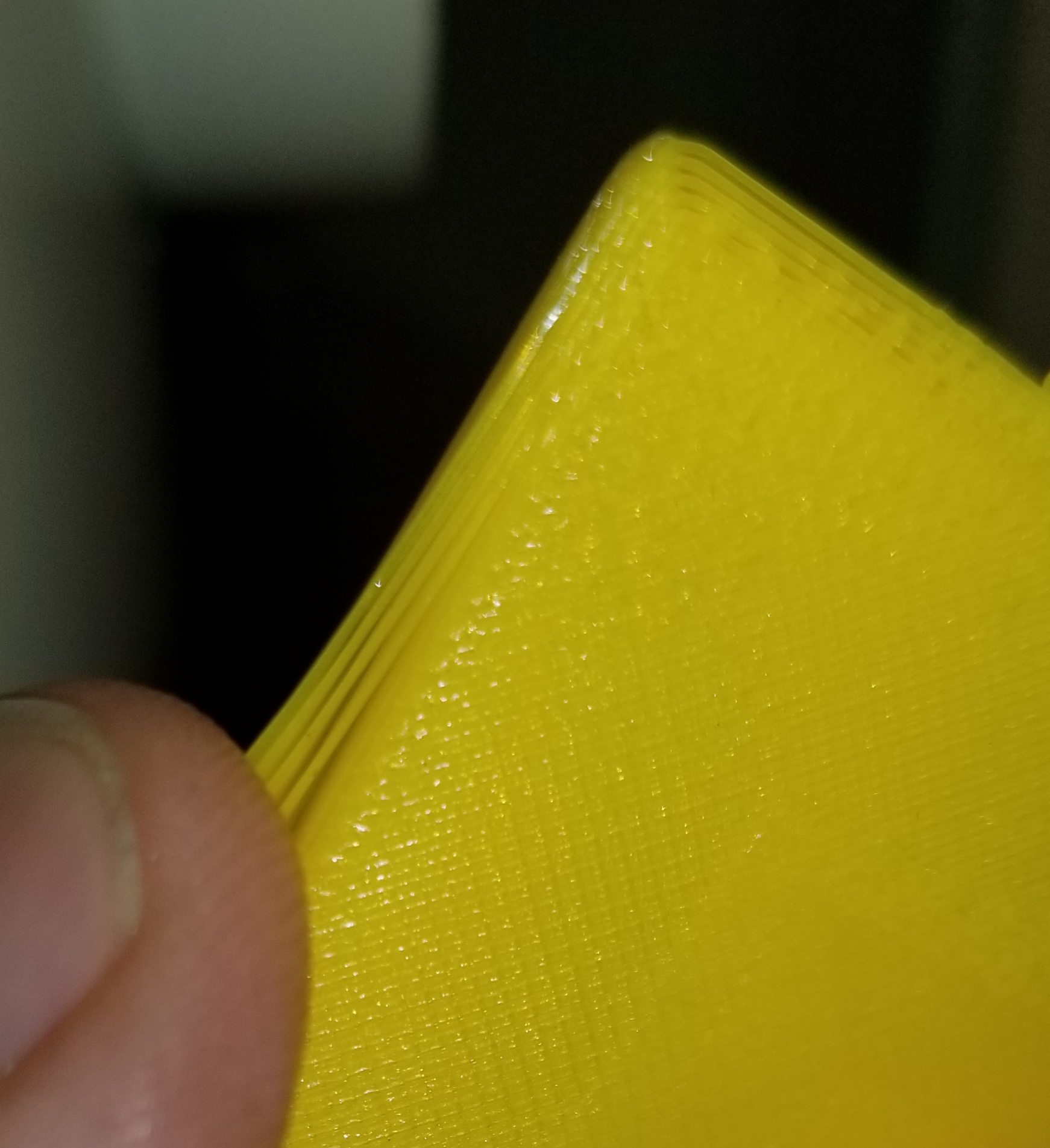

Yes it does. Bad news it the gear handle won’t last long. Needs to be metallic.Yep, that is what I bought. EZR Struder. Man, that plunger takes some super thumbs to push in, doesn't it!