- Messages

- 10,063

- Reaction score

- 24,716

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

I would like to introduce to you a new project of mine. This one is going to be called Aero Max as the goal was to reduce the aerodynamic frontal area of a 1/7 scale-sized car. It will be a speed runner so I have placed it in the speed run builds part of the forum.

This project has 3 phases.

For your viewing pleasure, this is Phase I and currently where I am at.

I have been told by @Tex Koder that this is going to blow some minds and I hope it does!!! The real mind-blowing part will be revealed later, in Phase II of the project, but Phase I is very cool already and I just had to share with you where it is at for now.

I also hope that it inspires you to build something unique and handmade. You will see in the following photos that I am using simple materials that anyone can obtain. No special tools that you likely do not already own. DO IT, make something interesting!!!

Materials list:

I like this Loctite foam best over some others as it has far fewer bubbles developed inside and is very dense which makes it great for shaping.

The initial goal here is to shape a body very slip-fitting to the chassis and able to fit 2 reasonably sized 3cell LiPo packs. I have no interest in making the body shaped for downforce, just the ultimate slim/slippery shape. More on downforce in the next post.

I put tape on top of a board so I can move the car around. On the tape, I applied wax and this keeps the foam from sticking. The Foam does stick to the press and seal glad wrap which you want so that when you sand on it the foam stays attached to the car. (Yes it looks like a giant glob of marshmallows, shaving cream, or whipped cream)

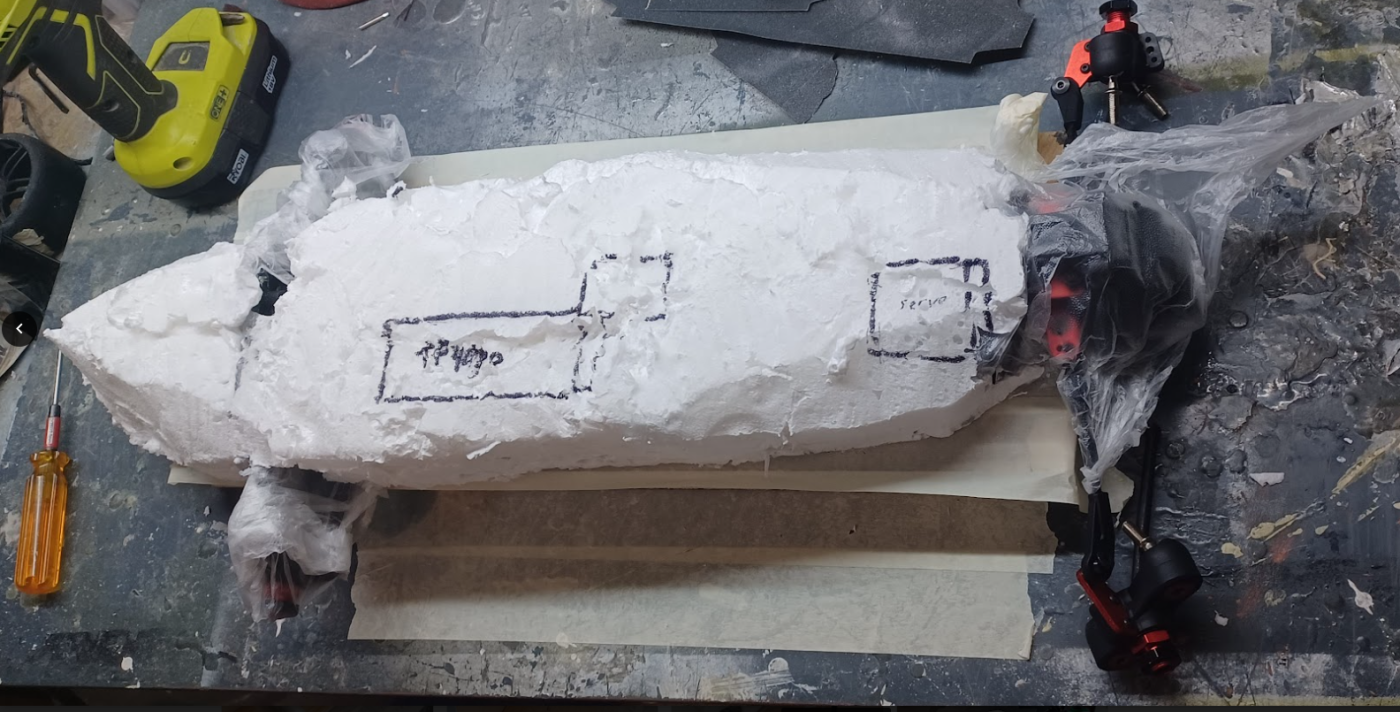

After letting this solidify for a day I began rough shaping with the serrated kitchen knife. Inside is the TP4070, motor mount, and servo so that I could determine how tall the body needs to be. I would use a hex wrench and poke through the foam to see how far down these components were.

This was after the first round of rough cuts.

After this I did some more cutting to round the shape and would then switch over to a sanding block with 150 grit paper for some fine shaping.

At this point you can see a nice rounded profile is starting to take shape and looking much better!

So what is next and how do we get some downforce into the design? I am glad you asked

Foam shaping on the a-arm to make the a-arms into wings or airfoils of course! Prepare to have your mind blow part 1.

Just like before they start as cream puffs

(I taped over the ends to not distrub the mounting points)

Lots of cutting and sanding to get them into the shape needed.

For all of these parts they will be skinned in fiberglass.

I built a simple Jig to hold the arms while I drapped fiberglass mat over the shape. 1 to 2 layers was all it needed.

*** Reminder safety first!!! Gloves, mask, fans / ventillation are highly recommended ***

Pre-cutting your fiberglass into managable sizes before starting makes the work considerably less frustrating! I also prefer the chip brushes about hald the brush lengh and just cut them with scissors before beginning.

After fiberglass installed on the arms.

After this I used a Dremmel tool to clean up the edges and cut off excess fiberglass.

Final product, Due to the steering link the lower arm is pretty mild and the upper arm has a more agressive airfoil camber angle. I may need to reduce this but figured I would start out agressive with high downfroce initially.

Here is a view of just how compact this car is going to be compared to the Delta Plastiks WR Speed body!

Reducing the aero drag should net significnatly more efficient speed runs!?

This is where I am at for now! I hope you enjoy it and feel inspired!!!!!

More to come as I work on this further!

This project has 3 phases.

For your viewing pleasure, this is Phase I and currently where I am at.

I have been told by @Tex Koder that this is going to blow some minds and I hope it does!!! The real mind-blowing part will be revealed later, in Phase II of the project, but Phase I is very cool already and I just had to share with you where it is at for now.

I also hope that it inspires you to build something unique and handmade. You will see in the following photos that I am using simple materials that anyone can obtain. No special tools that you likely do not already own. DO IT, make something interesting!!!

Materials list:

- Arrma 6s car (Mojave Chassis, Mojave front arms, Senton rear arms.)

- Loctite expanding foam

- Sheetrock joint compound

- Fiberglass mat

- Polyester resin

- 1.5” chip brush

- Sanding block with 150 grit sandpaper

- Serrated kitchen knife

- Painter’s tape

- Wax (car wax or any type really)

- Glad cling wrap

- Dremmel tool

I like this Loctite foam best over some others as it has far fewer bubbles developed inside and is very dense which makes it great for shaping.

The initial goal here is to shape a body very slip-fitting to the chassis and able to fit 2 reasonably sized 3cell LiPo packs. I have no interest in making the body shaped for downforce, just the ultimate slim/slippery shape. More on downforce in the next post.

I put tape on top of a board so I can move the car around. On the tape, I applied wax and this keeps the foam from sticking. The Foam does stick to the press and seal glad wrap which you want so that when you sand on it the foam stays attached to the car. (Yes it looks like a giant glob of marshmallows, shaving cream, or whipped cream)

After letting this solidify for a day I began rough shaping with the serrated kitchen knife. Inside is the TP4070, motor mount, and servo so that I could determine how tall the body needs to be. I would use a hex wrench and poke through the foam to see how far down these components were.

This was after the first round of rough cuts.

After this I did some more cutting to round the shape and would then switch over to a sanding block with 150 grit paper for some fine shaping.

At this point you can see a nice rounded profile is starting to take shape and looking much better!

So what is next and how do we get some downforce into the design? I am glad you asked

Foam shaping on the a-arm to make the a-arms into wings or airfoils of course! Prepare to have your mind blow part 1.

Just like before they start as cream puffs

(I taped over the ends to not distrub the mounting points)

Lots of cutting and sanding to get them into the shape needed.

For all of these parts they will be skinned in fiberglass.

I built a simple Jig to hold the arms while I drapped fiberglass mat over the shape. 1 to 2 layers was all it needed.

*** Reminder safety first!!! Gloves, mask, fans / ventillation are highly recommended ***

Pre-cutting your fiberglass into managable sizes before starting makes the work considerably less frustrating! I also prefer the chip brushes about hald the brush lengh and just cut them with scissors before beginning.

After fiberglass installed on the arms.

After this I used a Dremmel tool to clean up the edges and cut off excess fiberglass.

Final product, Due to the steering link the lower arm is pretty mild and the upper arm has a more agressive airfoil camber angle. I may need to reduce this but figured I would start out agressive with high downfroce initially.

Here is a view of just how compact this car is going to be compared to the Delta Plastiks WR Speed body!

Reducing the aero drag should net significnatly more efficient speed runs!?

This is where I am at for now! I hope you enjoy it and feel inspired!!!!!

More to come as I work on this further!