looks pretty small sectional density wise. great job man!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mojave Project Aero Max - Arrma 6s based speed runner

- Thread starter LibertyMKiii

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

- Messages

- 1,531

- Reaction score

- 2,415

- Location

- Bozeman, MT

- Arrma RC's

- Felony

- Granite

- Infraction

- Limitless

- Kraton 6s

- Nero

- Raider

- Senton 3s

- Talion

- Typhon 6s

- Vorteks

Wouldn't that be higher sectional density since the amount of car is the same with reduced cross sectional area?looks pretty small sectional density wise. great job man!

pretty small (frontal area) but yes you're right, higher overall sectional density.

Doom!

Team Dust Devil

Lifetime Premium!

Premium Member

ArrmaForum Fan

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 10,503

- Reaction score

- 22,471

- Location

- Central California

- Arrma RC's

- Gorgon

- Granite Grom

- Mojave

- Typhon 6s

I'm diggin' the post apocalyptic camo look.Been very busy with work lately but got in a few hrs of sanding.

Almost ready for paint on the main body. The wheel cowl still has a long way to go.

View attachment 259927

- Messages

- 10,063

- Reaction score

- 24,710

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

- Thread starter

- #125

Been working on several things lately with this car in CAD/3-D printing. Big thanks to @Tex Koder with an idea of what may have been wrong with my printer and he was right (dual Z-screws were not aligned.)

Out of the several things I am working on this little nugget is ready to show to you now. It is the rear arm/axle cover. There will be no rear upper a-arm (more on this later)

(more on this later)

This 3D printed part is a 2 Piece design that allows it to be removable. Now that I have decided to run it with no upper arm, I'll have to fill in that hole in the body where the upper arm went

Out of the several things I am working on this little nugget is ready to show to you now. It is the rear arm/axle cover. There will be no rear upper a-arm

This 3D printed part is a 2 Piece design that allows it to be removable. Now that I have decided to run it with no upper arm, I'll have to fill in that hole in the body where the upper arm went

Tex Koder

2D , 3D Not a problem. I'll take that Challenge.

Lifetime Premium!

Premium Member

ArrmaForum Fan

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 9,942

- Reaction score

- 24,963

- Location

- Dallas, TX (USA)

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Mojave

- Nero

- Senton 3s

- Typhon 6s

- Vendetta

Been working on several things lately with this car in CAD/3-D printing. Big thanks to @Tex Koder with an idea of what may have been wrong with my printer and he was right (dual Z-screws were not aligned.)

Glad to be of assistance buddy

Out of the several things I am working on this little nugget is ready to show to you now. It is the rear arm/axle cover. There will be no rear upper a-arm

No Upper linkage (Zero, Zip, Zilch, Nada) on the rear suspension arms!!

That's taking streamlining to a whole 'nother level!

This 3D printed part is a 2 Piece design that allows it to be removable. Now that I have decided to run it with no upper arm, I'll have to fill in that hole in the body where the upper arm went

View attachment 260788

Try using the clear plastic lids from a croissant box or a regular milk jugs as mending plate material ,to cover that hole.

Cheap, Plentiful and Easy to cut & work with.

You can double or triple layer it to stiffen up the area too.

- Messages

- 10,063

- Reaction score

- 24,710

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

- Thread starter

- #127

No Upper linkage (Zero, Zip, Zilch, Nada) on the rear suspension arms!!

That's taking streamlining to a whole 'nother level!

Thanks man!

Try using the clear plastic lids from a croissant box or a regular milk jugs as mending plate material ,to cover that hole.

Cheap, Plentiful and Easy to cut & work with.

You can double or triple layer it to stiffen up the area too.

View attachment 260804

I am going to use fiberglass to keep the body a consistent material and strong.

Last edited:

Wow this getting very interesting. Great job and super unique design like nothing I have so much as thought of. Incredible @LibertyMKiii

- Messages

- 1,531

- Reaction score

- 2,415

- Location

- Bozeman, MT

- Arrma RC's

- Felony

- Granite

- Infraction

- Limitless

- Kraton 6s

- Nero

- Raider

- Senton 3s

- Talion

- Typhon 6s

- Vorteks

Kindof off topic, but this video includes the very beginning of an early 00's late 90's Indy car, and there are a ton of cool little details if you are looking for them, like the airfoiled control arms. Might be able to get a couple ideas for this project, or others.

- Messages

- 10,063

- Reaction score

- 24,710

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

- Thread starter

- #130

***If all goes well with what I have built so far during testing....

I have been dreaming today about a later phase of the project where the airfoil arms will be dynamic wings that can be driven off a microcontroller and go through a range of motion depending on the throttle input or braking, aggressive angle of attack at lower speeds then reduce that angle when the throttle input is over 50% up till 100%. Then stand back up for aiding in braking.

I took a brief look at RC plane hinges today and don't like anything I had seen. Most were plastic. I see most of the large-scale plane guys make their own using a metal tube or part of the main wood structure with bushings. I could see the leverage of the airfoil providing 10 + lbs force at extremely high speeds, so I may just have to make something....

The hinge may be the easy part. I am a little unsure how I would drive the action. My initial thoughts were maybe a metal bar across with gears inside the airfoil. The only issue there is that the suspension is going to move so the gear mesh might not hold

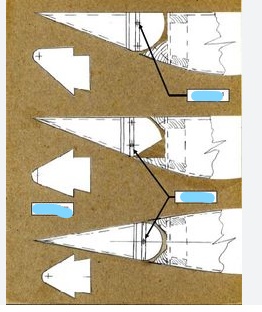

I like this top shape the best for what I would need:

I have been dreaming today about a later phase of the project where the airfoil arms will be dynamic wings that can be driven off a microcontroller and go through a range of motion depending on the throttle input or braking, aggressive angle of attack at lower speeds then reduce that angle when the throttle input is over 50% up till 100%. Then stand back up for aiding in braking.

I took a brief look at RC plane hinges today and don't like anything I had seen. Most were plastic. I see most of the large-scale plane guys make their own using a metal tube or part of the main wood structure with bushings. I could see the leverage of the airfoil providing 10 + lbs force at extremely high speeds, so I may just have to make something....

The hinge may be the easy part. I am a little unsure how I would drive the action. My initial thoughts were maybe a metal bar across with gears inside the airfoil. The only issue there is that the suspension is going to move so the gear mesh might not hold

I like this top shape the best for what I would need:

- Messages

- 1,582

- Reaction score

- 4,779

- Location

- Maryland

- Arrma RC's

- Infraction

- Limitless

- Mojave EXB

- Senton 3s

- Talion

- Typhon 3s

- Vendetta

That would be awesome,***If all goes well with what I have built so far during testing....

I have been dreaming today about a later phase of the project where the airfoil arms will be dynamic wings that can be driven off a microcontroller and go through a range of motion depending on the throttle input or braking, aggressive angle of attack at lower speeds then reduce that angle when the throttle input is over 50% up till 100%. Then stand back up for aiding in braking.

I took a brief look at RC plane hinges today and don't like anything I had seen. Most were plastic. I see most of the large-scale plane guys make their own using a metal tube or part of the main wood structure with bushings. I could see the leverage of the airfoil providing 10 + lbs force at extremely high speeds, so I may just have to make something....

The hinge may be the easy part. I am a little unsure how I would drive the action. My initial thoughts were maybe a metal bar across with gears inside the airfoil. The only issue there is that the suspension is going to move so the gear mesh might not hold

I like this top shape the best for what I would need:

View attachment 262927

Kind of like Travis Pastranas new Audi gymkhana car, with the active aero for braking

- Messages

- 10,063

- Reaction score

- 24,710

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

- Thread starter

- #133

Yep that thing is sweet!That would be awesome,

Kind of like Travis Pastranas new Audi gymkhana car, with the active aero for braking

RadioHacktive

Very Active Member

It's actually a Subaru GL Wagon dubbed "The Family Huckster". Block's the one with the Audi hoon machine ... and it's electric at that.That would be awesome,

Kind of like Travis Pastranas new Audi gymkhana car, with the active aero for braking

More to the topic: when an idea strikes and the part doesn't exist, 3d printing is a godsend. I can tell this project is incredibly serious if you're encasing suspension components in aero.

I'd research bellcranks and levers, much more likely to be able to mount the servo remotely and use a bit of rod and a bellcrank to pivot things upward. or put the dynamic downforce in the body voids instead of the arms (going to look like actual airplane arms at that point with all the electronic guts!)

- Messages

- 10,063

- Reaction score

- 24,710

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

- Thread starter

- #136

I'd research bellcranks and levers, much more likely to be able to mount the servo remotely and use a bit of rod and a bellcrank to pivot things upward. or put the dynamic downforce in the body voids instead of the arms (going to look like actual airplane arms at that point with all the electronic guts!)

Wow that is freaky! Do you have a hidden camera in my garage????

To clear the steering bits I'll have to put some bend in it. If I use ball bearings in the center section (which I plan to) This may have to be a 3 piece part given that you cannot slide ball bearinds down a rod with all sorts of bends in it.

- Messages

- 10,063

- Reaction score

- 24,710

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

- Thread starter

- #137

Alright, alright, alright I have been working on something secretly and I'll show you the back side of it to make this a little harder.

I want to see if you can tell me what it is for (all can play except for @Tex Koder who already knows)

I want to see if you can tell me what it is for (all can play except for @Tex Koder who already knows)

RadioHacktive

Very Active Member

Those look like the wheel weights for crawlers, BUT, I see that these were 3d printed and judging by your aero work for the a-arms, I'll say those are panels to smooth airflow behind the wheels.

- Messages

- 10,063

- Reaction score

- 24,710

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

- Thread starter

- #139

Nailed it!Those look like the wheel weights for crawlers, BUT, I see that these were 3d printed and judging by your aero work for the a-arms, I'll say those are panels to smooth airflow behind the wheels.

The plan is to run the car open wheel to see if it can set any records. I want to keep the air passing by the wheel and not trying to go inside of it.

RadioHacktive

Very Active Member

Welp, that's my smart thing for the day. If you need me, I'll be in the corner drooling.Nailed it!

The plan is to run the car open wheel to see if it can set any records. I want to keep the air passing by the wheel and not trying to go inside of it.

Similar threads

- Replies

- 3

- Views

- 569