Hello!

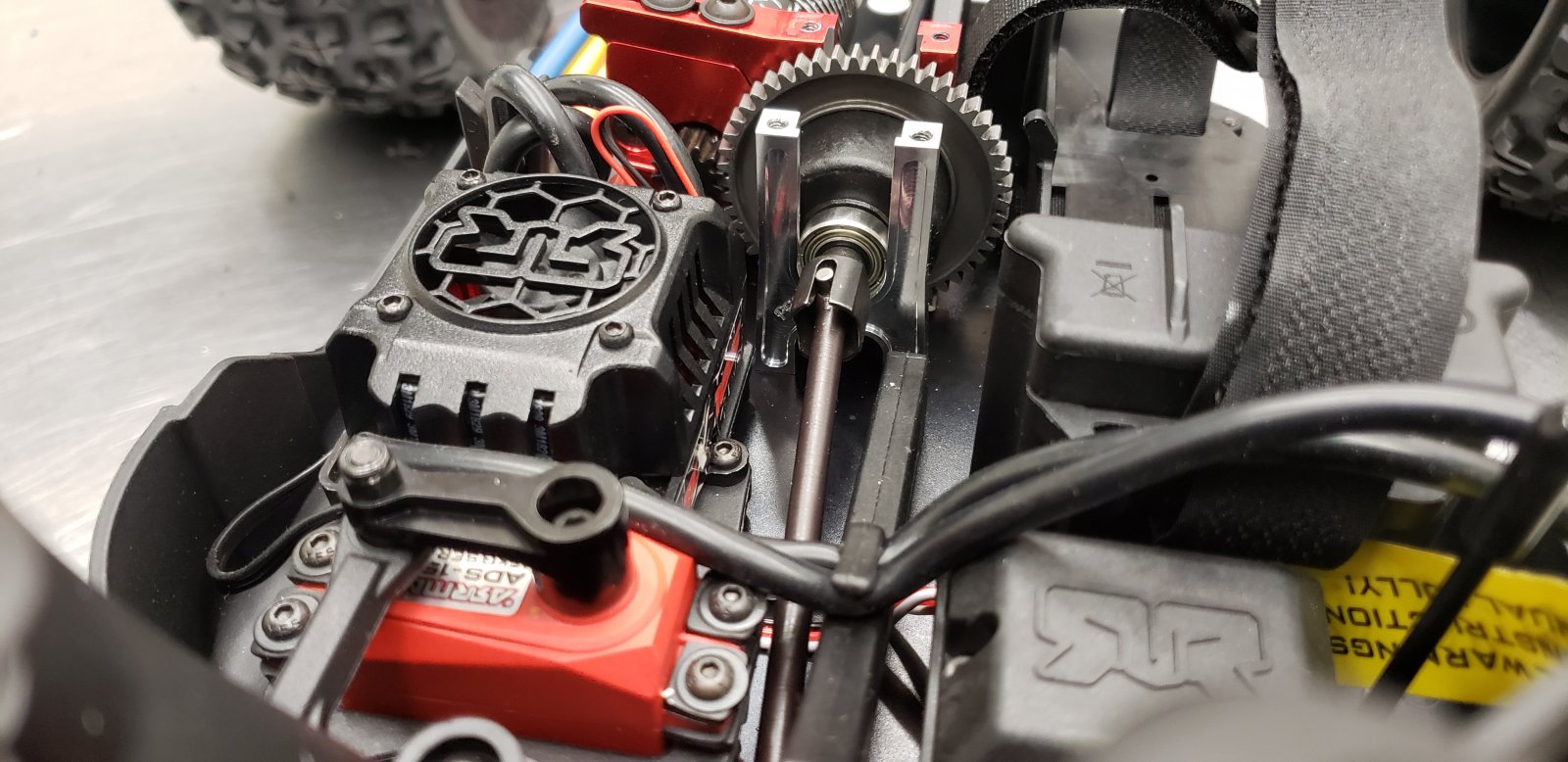

This is my V4 Kraton 6s I'm using for R&D of new products.

Molasses? Yup. Progress is going to be slow. I'm working as fast as I can, but am rushing nothing.

Billet? Darn Tootin.

I thought it would be cool to share my build log designing the parts that may end up in your build log. I figure, everyone else can be proud and show off their builds and I want in on that action!

Here is day 1 of my build. I think it's easy to forget what new used to look like! Haha

My first Arrma part I made is this PPS-RC.COM differential mount. It turned out awesome! And looks great in there.

And that's it for now.

I told you it was going to be slow. I'm playing the long game. Haha!

This is my V4 Kraton 6s I'm using for R&D of new products.

Molasses? Yup. Progress is going to be slow. I'm working as fast as I can, but am rushing nothing.

Billet? Darn Tootin.

I thought it would be cool to share my build log designing the parts that may end up in your build log. I figure, everyone else can be proud and show off their builds and I want in on that action!

Here is day 1 of my build. I think it's easy to forget what new used to look like! Haha

My first Arrma part I made is this PPS-RC.COM differential mount. It turned out awesome! And looks great in there.

And that's it for now.

I told you it was going to be slow. I'm playing the long game. Haha!