- Messages

- 1,755

- Reaction score

- 3,176

- Location

- Wenatchee, WA

- Arrma RC's

- 4x4-Mega

- BigRock 4x4

- Felony

- Granite

- Infraction

- Limitless

- Kraton 6s

- Outcast 4s

- Typhon 3s

- Voltage

So my first Arrma was the Arrma Voltage and have since bought/built up many other Arrma models and the Voltage just doesn't get run that much at all. Since it's not really worth selling and I don't really have any uses for it I slowly been doing stuff to it just for fun. I been randomly modding the truck since January and thought I'd share since the Voltage doesn't get as much love around here

Current mods:

Upcoming plans in the future if I don't lose interest and get around to them:

Current mods:

- Brushless 60A no-name ESC (supports 2s or 3s) + 3650 sized 4300kv motor + FlySky FS-GT3c radio/receiver

- Arrma ADS-15M Servo

- T-Bone front/rear bumper + wheelie bar (like it needs a wheelie bar but still)

- Metal diff outdrive cups with locked rear diff

- Speedtread Speedhawk wheels/tires

- 40mm/5v fan w/ blue LED in it, originally intended for a Raspberry Pi I think

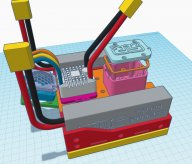

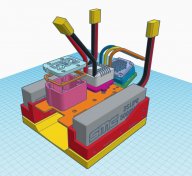

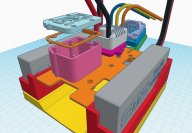

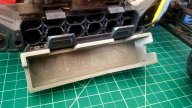

- My own designed 3D printed top plate

- Currently a prototype, more work to be done on this. Designed in a way that the underside has rooms for cable management, making install cleaner

- 3D printed receiver box

- Arrma 3s/4s wing mount with turnbuckle rear braces to secure the rear to the body

- Custom 3D printed TPU wing

Upcoming plans in the future if I don't lose interest and get around to them:

- Upgrade to better ESC/brushless motor (probably will use something I pull off another truck if/when I upgrade one of those to something else)

- Refine the design for my Lipo "Saddle Bags"

- These are 2s Lipo battery trays I design to add to the sides of the chassis so I could run 4s with 2 x 2s packs. I may or may not make it so I can keep using the stock battery bay. These are shown in the pictures but not yet functional and more so there for proof of concept.

- Refine 3D printed top plate and make it a multi part print with incorporated mounts for a printed receiver box, motor fan mount, and mounting points for lipo saddle bags.

- Might even abandon saddle bags and just widen the tray with additional body mounts/supports and lay it out more like the 3s chassis layout

- Replace stock shocks with metal oil filled w/ stiff springs

- Replace plastic turnbuckles/end links with metal/adjustable

- Replace stock steering horn

- Design custom lower skid plate intended to reinforce the weak chassis and mount with top plate and/or lipo saddle bags

- Design custom motor cover, wanting to make one would allow me to fabricate a custom made slipper/spur assembly to replace the weak plastic spur/gear combo

- Fabricate a way to replace the crappy plastic motor mount points and add a dedicated plate with adjustable mesh

- Kind of a just a wish at this point, not sure if it can really be done with the voltage chassis how it is

Attachments

-

20200501_133740.jpg365.6 KB · Views: 627

20200501_133740.jpg365.6 KB · Views: 627 -

20200501_133753.jpg310.7 KB · Views: 262

20200501_133753.jpg310.7 KB · Views: 262 -

20200501_133945.jpg305 KB · Views: 232

20200501_133945.jpg305 KB · Views: 232 -

20200501_133808.jpg524.7 KB · Views: 218

20200501_133808.jpg524.7 KB · Views: 218 -

20200501_133839.jpg248 KB · Views: 262

20200501_133839.jpg248 KB · Views: 262 -

20200501_133910.jpg174.8 KB · Views: 235

20200501_133910.jpg174.8 KB · Views: 235 -

20200501_133926.jpg193.5 KB · Views: 234

20200501_133926.jpg193.5 KB · Views: 234 -

20200501_134305.jpg319.5 KB · Views: 243

20200501_134305.jpg319.5 KB · Views: 243 -

20200501_134251.jpg140.5 KB · Views: 226

20200501_134251.jpg140.5 KB · Views: 226 -

20200501_134223.jpg256.2 KB · Views: 216

20200501_134223.jpg256.2 KB · Views: 216 -

20200501_134239.jpg228.9 KB · Views: 227

20200501_134239.jpg228.9 KB · Views: 227 -

20200501_134002.jpg478.4 KB · Views: 238

20200501_134002.jpg478.4 KB · Views: 238

Last edited: