Weather is seriously nice and sunny here in the UK and I thought I'll start wrenching a bit on my Kraton 8S as I had a few parts on the shelf for a while but not done anything.

While at it, probably worth to start documenting all the changes I'll do to it.

My Kraton 8S is the fast one (green) original batch and the only thing I had replaced was the radio as I use my Spektrum Dx5 Pro with it.

Shock Socks

The first undocumented change was to install some shock socks to keep the shocks a bit more clean especially in dusty conditions and I got a set off ebay at a reasonable price I think https://ebay.us/r0tf9J

Light Kit

After the shock socks were installed I went and got a light kit off ebay from the same seller that supplied the shock socks (could have saved some postage here ...) https://ebay.us/AxUK6h

The light kit looks seriously awesome even during the day, the material is TPU printed so it flexes instead of breaking during an uncontrolled landing.

Kraton 8S upgrades

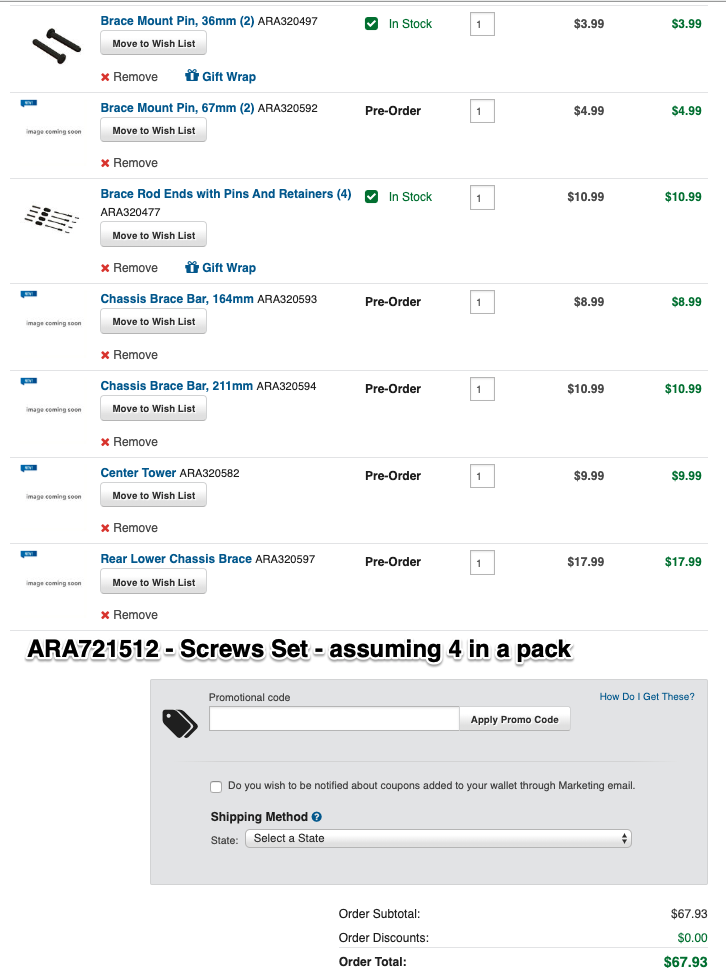

I couldn't be bothered to wait any longer and compiled a parts list by comparing the manuals of the first batch and newly released Kraton 8s. Information in the EU as to when potentially upgrade kits will be available, or at all, at the price like in the US for $25 or anything else so I went ahead and bought them out of pocket to install.

M2C Chassis

Well, it feels like forever that I have the M2C chassis sitting on the shelf which I got I believe from the first batch @Mitchell looper produced which got to me via @Badtouch The basher and his excellent services.

Today, as mentioned is a sunny day and I thought lets give it a shot and create a Kratonstein 8S 1.5V M2C

Obviously I had to strip the Kraton 8S to free the chassis to replace it with the M2C

While stripping it I noticed that the Suspension Hanger Set ARA330555 had been damaged - probably during one of the many cartwheels the truck has been through - never noticed it before so part# ARA330555 ordered and full completion I assume is postponed

here is the M2C chassis the way I will attempt to use it to include the upgraded rear brace into the setup

Front axis (edit: actually I think rear) and motor mount installed

Its amazing how easy this truck is to work on and the chassis is good machined so it goes together quite well or without many delays

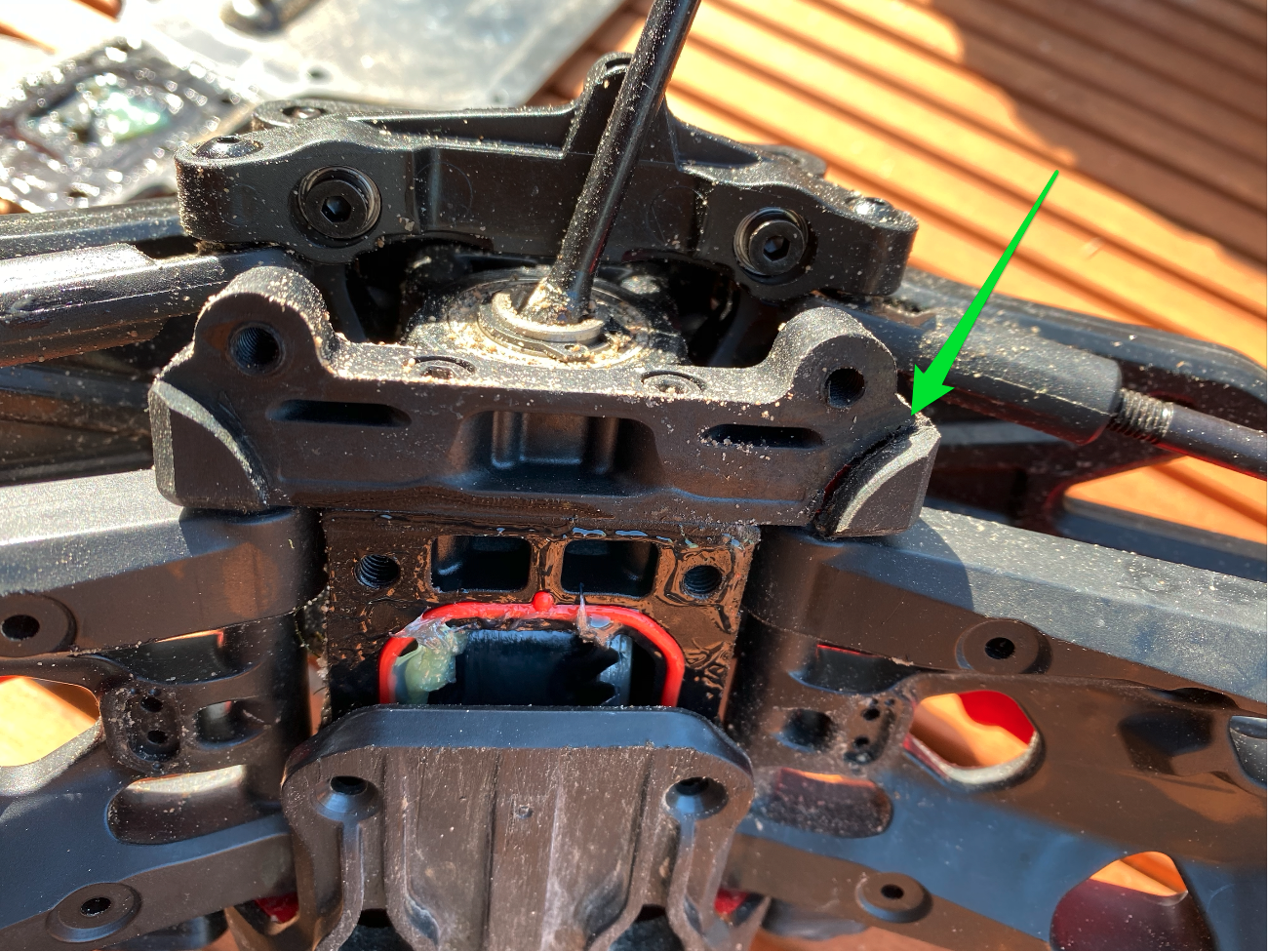

This is what you end up with if you want to include the upgraded rear brace into the setup - @Mitchell looper may be worth considering bringing a modified part into production to accommodate for this

But its nothing 2 M3 washers cant fix - I tried to squeeze 3 in there but you could see the stress while with 2 washers it was nice and snug

these two fellas however seemed to cause a bit of a challenge as it seemed somehow they were like 2mm off it took me a serious amount of try and error screwing bits together before they would fit while the other holes perfectly lined up - not sure what was wrong here but I got there in the end

So I don't lose any parts or screws I did put everything back together until the Suspension Hanger gets here and my Red and Tacky.

Postponed work for now:

Carbon Fibre Tubing

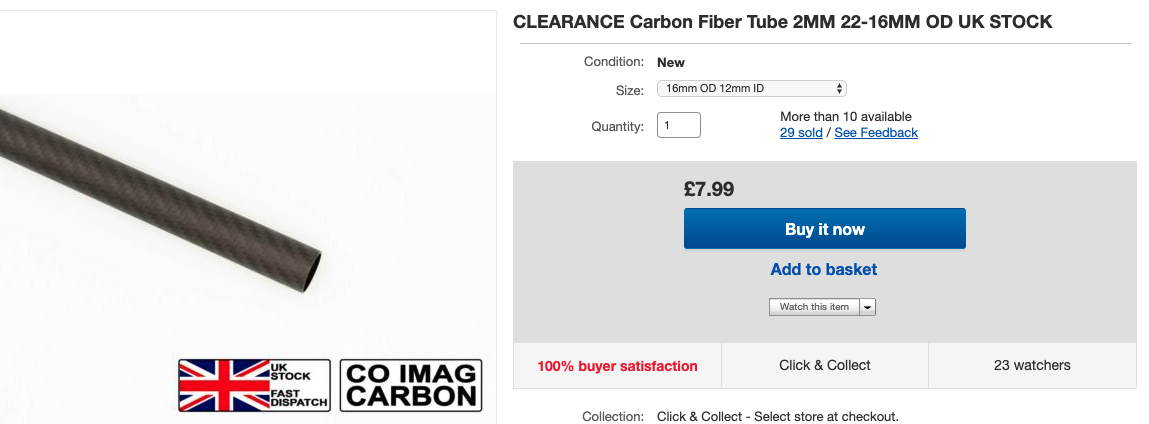

Assuming the weather tomorrow is similar to today I will then strengthen the different chassis brace bars with the carbon tubes that have arrived today (2x OD16mm,ID12mm,50cm) which were finally somewhere available for me here in the UK again via ebay https://ebay.us/c2nJau

Bulletproof shock rod ends

I also bought some alternative shock rod ends I intended to put on the Kraton which I also got off ebay: https://ebay.us/v4sJZb

These shock rod ends apparently fit perfectly according to youtube UNRooted RC so I'll give it a shot.

So waiting for the spare part and grease before I can progress and put the last bits on for now ...

While at it, probably worth to start documenting all the changes I'll do to it.

My Kraton 8S is the fast one (green) original batch and the only thing I had replaced was the radio as I use my Spektrum Dx5 Pro with it.

Shock Socks

The first undocumented change was to install some shock socks to keep the shocks a bit more clean especially in dusty conditions and I got a set off ebay at a reasonable price I think https://ebay.us/r0tf9J

Light Kit

After the shock socks were installed I went and got a light kit off ebay from the same seller that supplied the shock socks (could have saved some postage here ...) https://ebay.us/AxUK6h

The light kit looks seriously awesome even during the day, the material is TPU printed so it flexes instead of breaking during an uncontrolled landing.

Kraton 8S upgrades

I couldn't be bothered to wait any longer and compiled a parts list by comparing the manuals of the first batch and newly released Kraton 8s. Information in the EU as to when potentially upgrade kits will be available, or at all, at the price like in the US for $25 or anything else so I went ahead and bought them out of pocket to install.

M2C Chassis

Well, it feels like forever that I have the M2C chassis sitting on the shelf which I got I believe from the first batch @Mitchell looper produced which got to me via @Badtouch The basher and his excellent services.

Today, as mentioned is a sunny day and I thought lets give it a shot and create a Kratonstein 8S 1.5V M2C

Obviously I had to strip the Kraton 8S to free the chassis to replace it with the M2C

While stripping it I noticed that the Suspension Hanger Set ARA330555 had been damaged - probably during one of the many cartwheels the truck has been through - never noticed it before so part# ARA330555 ordered and full completion I assume is postponed

here is the M2C chassis the way I will attempt to use it to include the upgraded rear brace into the setup

Front axis (edit: actually I think rear) and motor mount installed

Its amazing how easy this truck is to work on and the chassis is good machined so it goes together quite well or without many delays

This is what you end up with if you want to include the upgraded rear brace into the setup - @Mitchell looper may be worth considering bringing a modified part into production to accommodate for this

But its nothing 2 M3 washers cant fix - I tried to squeeze 3 in there but you could see the stress while with 2 washers it was nice and snug

these two fellas however seemed to cause a bit of a challenge as it seemed somehow they were like 2mm off it took me a serious amount of try and error screwing bits together before they would fit while the other holes perfectly lined up - not sure what was wrong here but I got there in the end

So I don't lose any parts or screws I did put everything back together until the Suspension Hanger gets here and my Red and Tacky.

Postponed work for now:

Carbon Fibre Tubing

Assuming the weather tomorrow is similar to today I will then strengthen the different chassis brace bars with the carbon tubes that have arrived today (2x OD16mm,ID12mm,50cm) which were finally somewhere available for me here in the UK again via ebay https://ebay.us/c2nJau

Bulletproof shock rod ends

I also bought some alternative shock rod ends I intended to put on the Kraton which I also got off ebay: https://ebay.us/v4sJZb

These shock rod ends apparently fit perfectly according to youtube UNRooted RC so I'll give it a shot.

So waiting for the spare part and grease before I can progress and put the last bits on for now ...

Last edited: