Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Typhon rear diff spiral gear grinding on M2C chassi

- Thread starter Niz55

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,870

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

Still running the stock chassis and stock bulkhead housing. I have diff gear rubbing marks on it also. Front and rear. In my case probably from chassis flex when bashing in my case. The gears are very close. Maybe the M2C diff gear recessed areas on the chassis were not machined deep enough? Replace one HR diff housing with the plastic one and see if there is a difference in clearance. Mark that chassis grind spot with a black marker before you install the plastic one, to see if that mark is grinded off again. Either the HR housing or the M2C Chassis is not to spec.

You could dremel out the gear recess further to accomodate the ring gear better as one option. Does the diff assembly seem to spin free? or is it binding due to this? Others may chime in.

You could dremel out the gear recess further to accomodate the ring gear better as one option. Does the diff assembly seem to spin free? or is it binding due to this? Others may chime in.

Last edited:

- Thread starter

- #4

I did measure the dept of stock chassi notch and m2c. The stock chassi is slightly deeper.

I am thinking of grinding the chassi down a little or add spacers under the HR housing.

Still running the stock chassis and stock bulkhead housing. I have diff gear rubbing marks on it also. Front and rear. In my case probably from chassis flex when bashing in my case. The gears are very close. Maybe the M2C diff gear recessed areas on the chassis were not machined deep enough? Replace one HR diff housing with the plastic one and see if there is a difference in clearance. Mark that chassi grind spot with a black marker befor you install the plastic one, to see if that mark is grinded off again. Either the HR housing or the M2C Chassis not to spec.

You could dremel out the gear recess further to accomodate the ring gear as one option. Does the diff assembly seem to spin free? or is it binding due to this? Others may chime in.

It does bind a little but only at certain position. For example, if I spin the diff and start at 12 it will bind at 6 and after wards no binding at all until it hits 6 again.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,870

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

Spacers wont work because then there is no seal to keep dirt out of the housing. Housing must be flush to the chassis. Better to Dremel a slight bit at a time. Good luck. I am curious if others here have noticed this. Hopefully others chime in. I was also considering these HR and M2C parts. I've heard that this chassis requires a bit of finesse to install compared to the stock chassis. M2C appears to be the best chassis out there.

slick2500

Anything will break if you drive it wrong enough.

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 26,721

- Reaction score

- 42,027

- Location

- Rapid City, SD

- Arrma RC's

- Fireteam

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Senton 3s

- Typhon 3s

Now I want to check mine.Scratch the spacer idea because the housing won't be sealed. So I think I just have to grind it down.

I guess hr housing and m2c chassi is not quiet compatible with each other.

Haha posted same time you did. Thanks

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,870

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

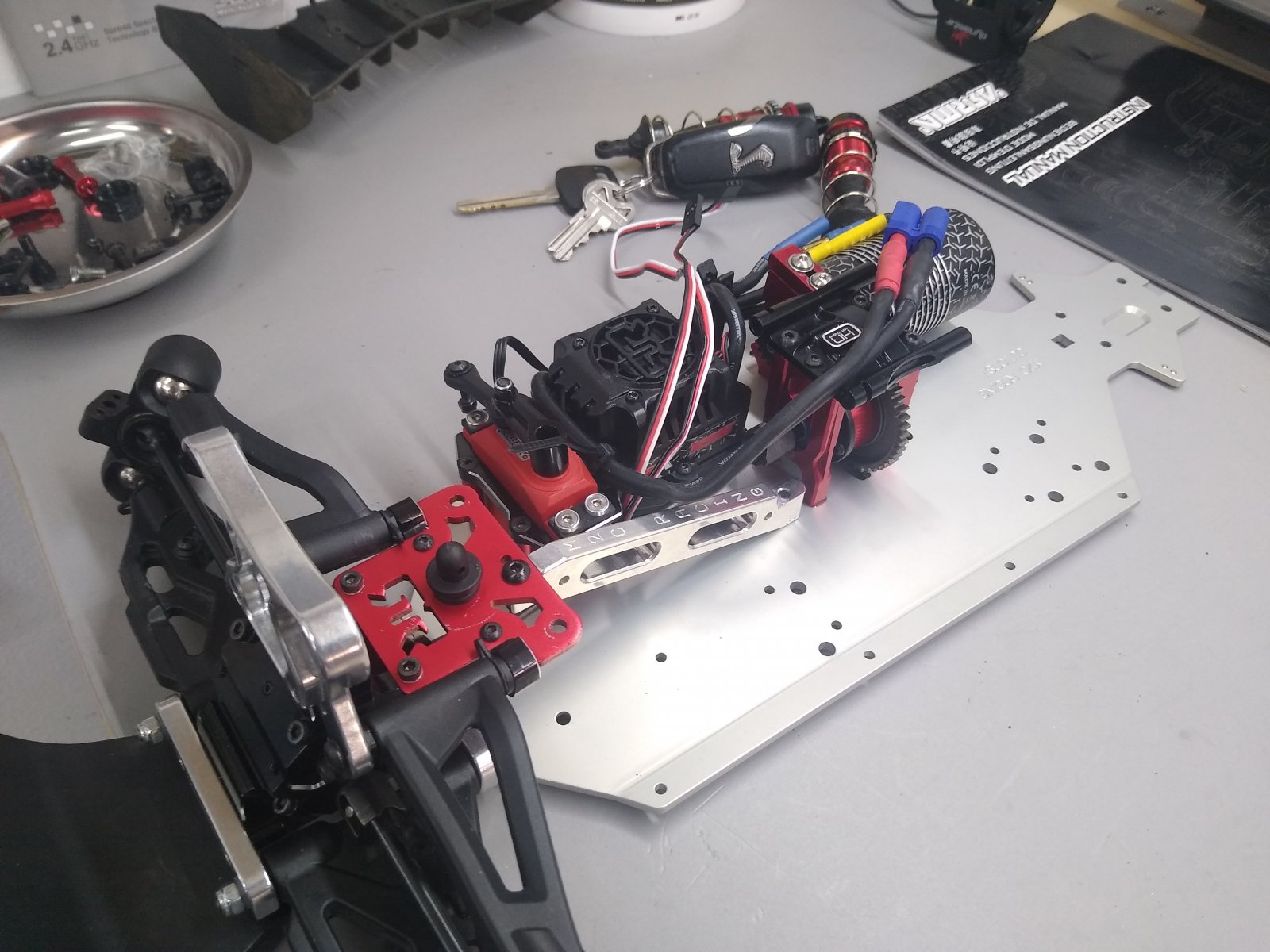

Just double check the diff cup screws to make sure the Ring gear is seated evenly onto the cup. If not there may be undue run out that's causing a slight rub. Use a caliper to measure the width of the cup at 4 places after it is tightened. That should show if there is any runout because the gear is not even and flush to the cup.View attachment 67113

I did measure the dept of stock chassi notch and m2c. The stock chassi is slightly deeper.

I am thinking of grinding the chassi down a little or add spacers under the HR housing.

It does bind a little but only at certain position. For example, if I spin the diff and start at 12 it will bind at 6 and after wards no binding at all until it hits 6 again.

- Thread starter

- #9

I am thinking it could be the m2c hinge pin support A block that is locked under the diff case. You do have to remove the factory bumper in order to install it. Maybe is it thicker than the factory bumper and causing it to sit at slight angle and rub against the chassi.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,870

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

Remove the Rear C and D blocks or Fronts ,A and B (hinge mount blocks) and screw mount just the HR bulkhead/diff housing to see if your logic holds true. Check for ring gear rubbing.

- Thread starter

- #11

Problem solved. it was the m2c chassi that was out of spec. I installed the whole diff assembly on the stock chassi and no problem. Had to use my Dremel to grind it down. Probably 1/2 mm left on the chassi and I hope it doesn't break and expose my diff. Sucks for all that money they should at least check the dept.

On the other hand, HR parts are very good quality and in my opinion better than m2c. The pins that come with the a and b block have such a weak thread. 3 times taking the nut off and it was shreading the threads.

On the other hand, HR parts are very good quality and in my opinion better than m2c. The pins that come with the a and b block have such a weak thread. 3 times taking the nut off and it was shreading the threads.

slick2500

Anything will break if you drive it wrong enough.

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 26,721

- Reaction score

- 42,027

- Location

- Rapid City, SD

- Arrma RC's

- Fireteam

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Senton 3s

- Typhon 3s

You should see my

Just fyi the stock chassis does this too. The diff can move up and down inside the gearbox especially on landings.Problem solved. it was the m2c chassi that was out of spec. I installed the whole diff assembly on the stock chassi and no problem. Had to use my Dremel to grind it down. Probably 1/2 mm left on the chassi and I hope it doesn't break and expose my diff. Sucks for all that money they should at least check the dept.

On the other hand, HR parts are very good quality and in my opinion better than m2c. The pins that come with the a and b block have such a weak thread. 3 times taking the nut off and it was shreading the threads.

- Thread starter

- #13

Completely understand that can happen . I haven't ran the car yet and it was rubbing against the chassi and this didn't happen on the stock. But anyways they are much better quality than stock parts.

Wish I had more time but taking it slowly.

Wish I had more time but taking it slowly.

slick2500

Anything will break if you drive it wrong enough.

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 26,721

- Reaction score

- 42,027

- Location

- Rapid City, SD

- Arrma RC's

- Fireteam

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Senton 3s

- Typhon 3s

Sorry I missed that part about you not even running it yet in your original post, so yeah that is not normal. I really should check mine.Completely understand that can happen . I haven't ran the car yet and it was rubbing against the chassi and this didn't happen on the stock. But anyways they are much better quality than stock parts.

Wish I had more time but taking it slowly.

View attachment 67409

slick2500

Anything will break if you drive it wrong enough.

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 26,721

- Reaction score

- 42,027

- Location

- Rapid City, SD

- Arrma RC's

- Fireteam

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Senton 3s

- Typhon 3s

Yup give me a minAnyone know where I can find these for the upper arm to adjust the caster? I need different varieties like 0.5mm and up. Doesn't really have to be arrma brand can be anything .View attachment 67416

Ar330366

Only goes down to 0.7mm though

https://www.amazon.com/dp/B01I5GYWV8/ref=cm_sw_r_other_apa_i_uglwEb9DMJYF4

slick2500

Anything will break if you drive it wrong enough.

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 26,721

- Reaction score

- 42,027

- Location

- Rapid City, SD

- Arrma RC's

- Fireteam

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Senton 3s

- Typhon 3s

Are those 4mm? Maybe try to find some 4mm shims or washers.I did buy that last week and the inner diameter is way too big even on the smallest one.

bicketybam

Back from vacation!

Lifetime Premium!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 13,394

- Reaction score

- 23,196

- Location

- New Milford, CT

- Arrma RC's

- BigRock 4x4

- Granite

- Infraction

- Kraton 8S

- Kraton 6s

- Kraton 4s

- Mojave

- Notorious

- Talion

- Typhon 6s

I had an issue like this with an M2C chassis. He replaced it for me.Completely understand that can happen . I haven't ran the car yet and it was rubbing against the chassi and this didn't happen on the stock. But anyways they are much better quality than stock parts.

Wish I had more time but taking it slowly.

View attachment 67409

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,870

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

Absolutely true dat. same here. There's just no discussion between M2c or Even JBI when comparing to stock. It flexes if you even look at on the shelf.You should see my

Just fyi the stock chassis does this too. The diff can move up and down inside the gearbox especially on landings.

View attachment 67398

Won't happen with a Goliath.

Landing under load and jumps causes this. I could see the ring gear eventually wearing a hole thru.