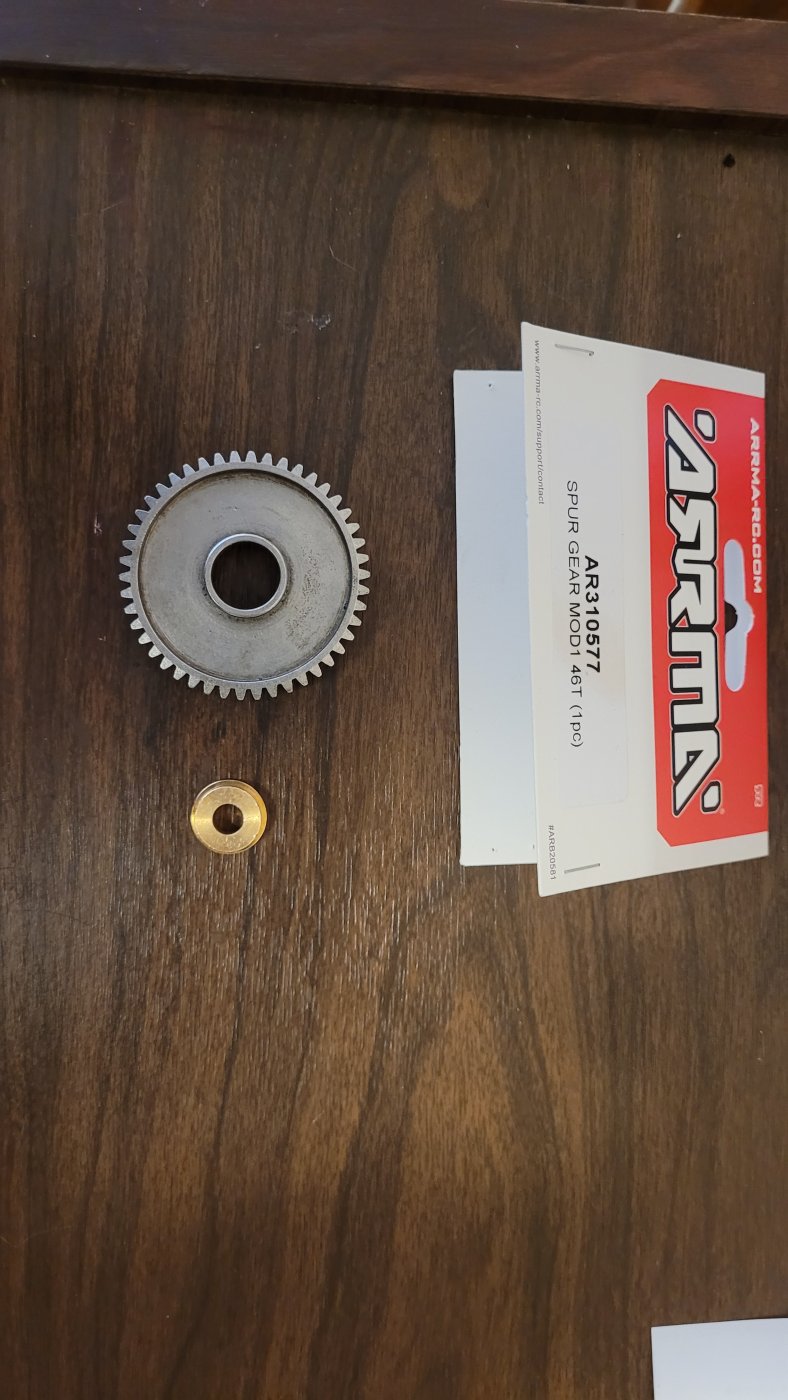

Received my spur gear and the bushing is not press fitted in and the 46T marking on the spur is non existant...

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Big Rock Received my spur gear...

- Thread starter Surchaufeur

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

Hector_Fisher

Very Active Member

How hard of a press fit is it? Hammerable, or no?Received my spur gear and the bushing is not press fitted in and the 46T marking on the spur is non existant...View attachment 295459

- Thread starter

- #3

I have no clue. Brass is pretty softHow hard of a press fit is it? Hammerable, or no?

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,869

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

Stick the brass bushing inside the freezer for 15 min. The brass will contract in size . Then Heat up the Spur with a Heat gun or hair dryer. The Spur will expand. So it is very hot to the touch, use gloves to handle it. Then quickly insert the brass bushing right out of the freezer. Should fit in/ slide in easily enough. Try that. As both metals get to room temps, the bushing should become nice and snug.

Let us know how it works out.

I would imagine the brass bushing in this application should be a very tight fit for best operation.

Brass Oilite bushings are soft. I would Not hammer it.

And No need to.

My 2 cents.

Let us know how it works out.

I would imagine the brass bushing in this application should be a very tight fit for best operation.

Brass Oilite bushings are soft. I would Not hammer it.

And No need to.

My 2 cents.

Last edited:

- Thread starter

- #5

I just ended up using my vice and a 21mm socketStick the brass bushing inside the freezer for 15 min. The brass will contract in size . Then Heat up the Spur with a Heat gun or hair dryer. The Spur will expand. So it is very hot to the touch, use gloves to handle it. Then quickly insert the brass bushing right out of the freezer. Should fit in/ slide in easily enough. Try that. As both metals get to room temps, the bushing should become nice and snug.

Let us know how it works out.

I would imagine the brass bushing in this application should be a very tight fit for best operation.

Brass Oilite bushings are soft. I would Not hammer it.

And No need to.

My 2 cents.

One of my spur got toasted my gearmesh was too tight and it ruined my brass bushing. I don't think it would be too hard to get one machined to spec or find one online

Wish arrma sold that part alone. Such a waste

- Thread starter

- #6

Amain decided to send me a new spur gear anyway. They got told by horizon it wasnt normal. Here is the new spur gear.

It can be a real issue if someone doesn't have the tools to press fit the part in. Still a bit bummed by this but i cant complain. Got a free spur for asking if it was normal for the spur to come seperated from its bushing

It can be a real issue if someone doesn't have the tools to press fit the part in. Still a bit bummed by this but i cant complain. Got a free spur for asking if it was normal for the spur to come seperated from its bushing

- Thread starter

- #8

Its pretty epic. I did end up breaking a front axle pin on my last run while trying a full throttle backflip. Im really cautious with it and i don't attempt to backflip. Handling is amazing. It sits bery high up and has 2 times more suspension clearence and travel than my other 6sHow is your Big Rock running these days?

Last edited:

The freezer trick works BTW, for anything metal your trying to fit into something else metal. Done it many times. If you don't have time to wait, use canned air held upside down. Wear gloves!!

- Thread starter

- #10

I ended up using my viceThe freezer trick works BTW, for anything metal your trying to fit into something else metal. Done it many times. If you don't have time to wait, use canned air held upside down. Wear gloves!!