Martinj7942

Fairly New Member

- Messages

- 9

- Reaction score

- 1

- Arrma RC's

- Talion

Anyone install rpm rear lower arms on a v4 talion? They don’t seem to have enough clearance between the hinge pin and diff casing for proper fitment. Is that the case here?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

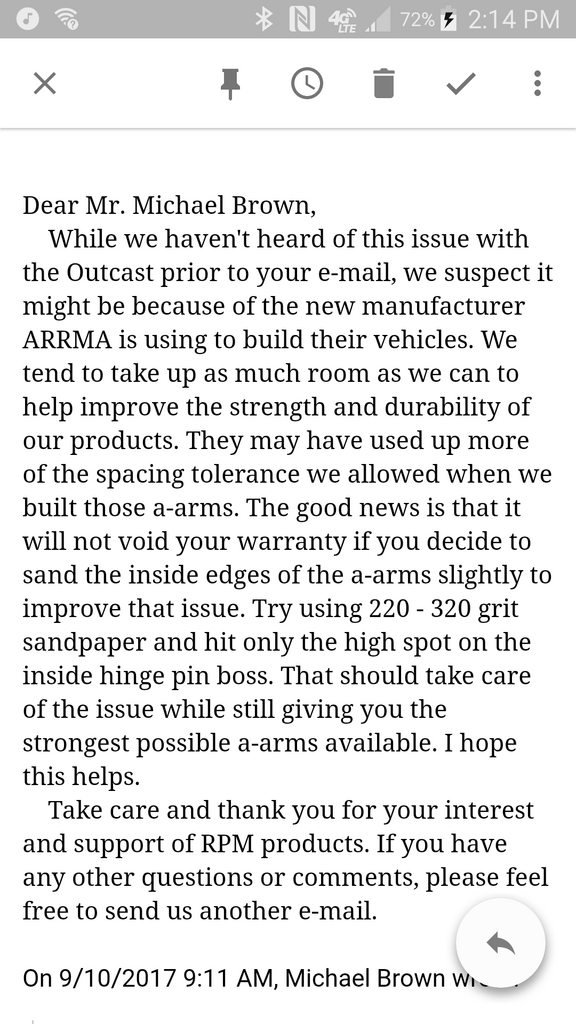

This is a known problem, Rpm of course blames Arrma.Looks like I’m gonna have to put these in a vise and bend some Emory cloth across about 150 degrees of the outer radius and take about 30 thou of material off, anyone else have to do this?

I've been beating on mine for a while that I sanded down, the holes the pin goes through seems to wear out before anything else does.Thank you for the InfoI’ll put them

In my mini Cnc and just make a small radius cut on the outer 180 and they should fit well. Hopefully the strength will not be compromised in any way. I’ll report once I beat the hell out of them.

I’m going to slightly modify the diff housing rather than your product. I feel that strength integrity is compromised far not in the arm than the diff housing as well as replacement arms will not require modification. The required amount for clearance seems to be less than 30 thousandths and is better suited to be removed from there than your product. Simply insight for you guys, not a recommendation for anyone else. Just my two cents.This is a known problem, Rpm of course blames Arrma.

https://www.arrmaforum.com/threads/rpm-rear-a-arms-binding.4730/

Yup the other day I posted on Facebook that I was pimping gas instead of pumping. And it tried to change it again ?Actually the more I look, them more I’m thinking of removing a small amount of material from the diff housing not the arm. Probably more productive for strength and longevity.

Probably going to notch the section that protrudes and give it a try. I’ll update once I confirm the idea

Minimally this will make a new arm set fit without modifications in the future so might be the best remedy.

I’m going to slightly modify the diff housing rather than your product. I feel that strength integrity is compromised far not in the arm than the diff housing as well as replacement arms will not require modification. The required amount for clearance seems to be less than 30 thousandths and is better suited to be removed from there than your product. Simply insight for you guys, not a recommendation for anyone else. Just my two cents.

More, not the word not. Auto correct will

Make us all look like a moron at some point.?

Register and gain access to Discussions, Reviews, Tech Tips, How to Articles, and much more - on the largest Arrma RC community for RC enthusiasts that covers all aspects of the Arrma-RC brand!

Register Today It's free! This box will disappear once registered!