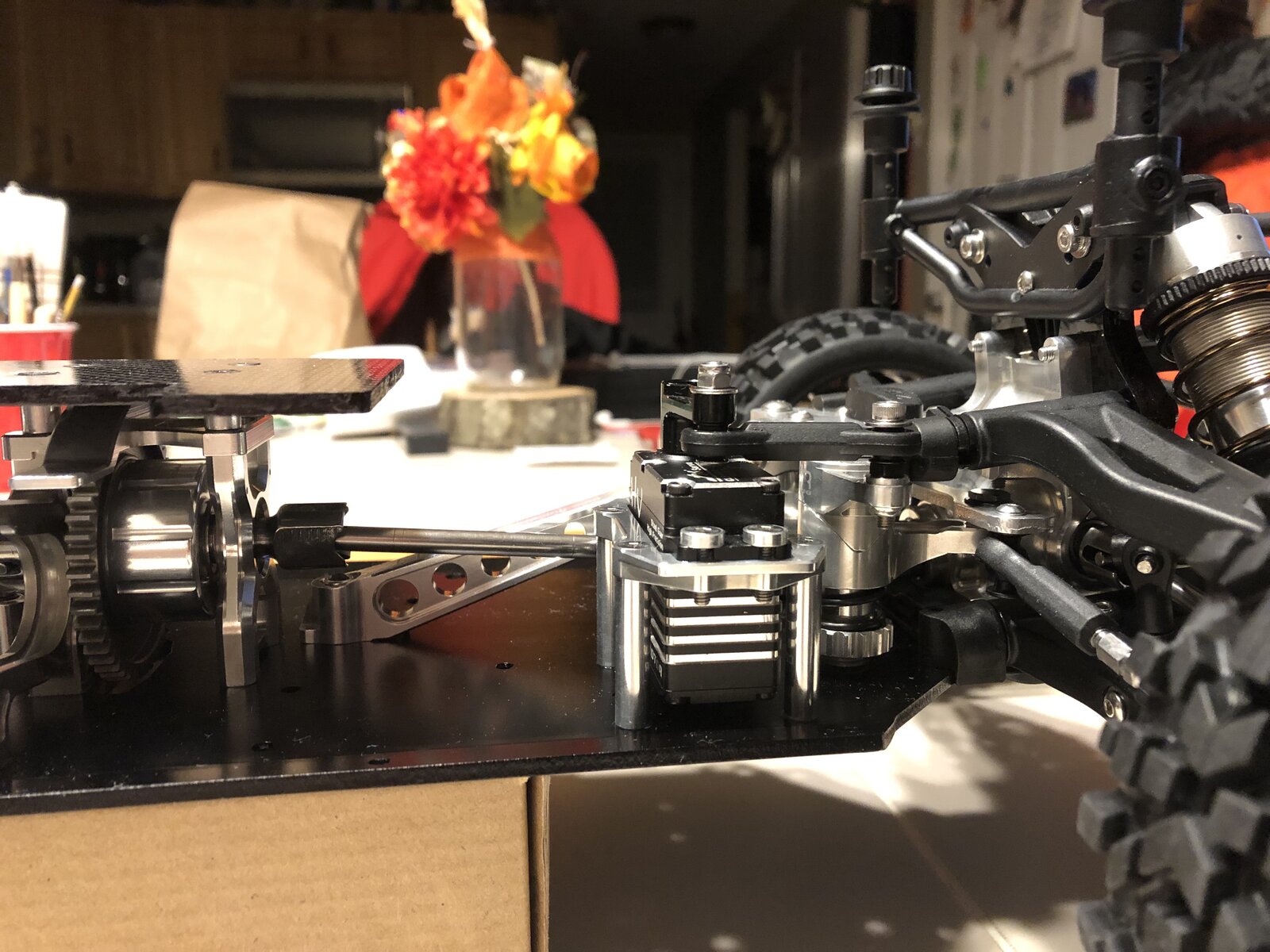

I have a Savox 1210SG and a Hot racing servo mount. Do I install the servo from under the mount or on top?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Savox/HR servo mount install help!

- Thread starter Walküre

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

What is the issue exaclty? There doesn’t seem to be enough room for the wire? It should fit but will require a bit of finagling. It’s the same on the stock servo mount.

No, I would use the rubber bushings with the grommets and mounted on top.

The rubber absorbs impacts and takes some stress off the servo.

The rubber absorbs impacts and takes some stress off the servo.

- Thread starter

- #6

The original issue I had was mounting the servo with the supplied rubber deals. It was to high. I still used a couple stainless washers between the steering rack and the servo link to get it straighter.

- Thread starter

- #7

When I did that it was super tall. I’ll redo it if it’s normal protocol. I don’t want to buy another. You scared me into it, lol.No, I would use the rubber bushings with the grommets and mounted on top.

The rubber absorbs impacts and takes some stress off the servo.

- Thread starter

- #8

Thanks for the help. I tried to attach a video so you guys can hear this servo. It sounds like one of the gears makes light clicking noises in the same spot when moved manually. I’ve never had a cordless servo before.

- Thread starter

- #9

What did you use for spacers on your servo arm? I need something to straighten out the steering servo link.

That’s looking good! Definitely keep the rubber grommets in there. I used nylon spacers that I bought from my local hardware store (Ace Harware) I bought 1/8” and 1/4” thick ones but can’t remember the lengths I used in that application....I wanna say 1/8”.

When you go, just buy a bunch of aluminum and nylon spacers and washers that fit M3 screws...they are cheap and will definitely come in handy when you need them.

When you go, just buy a bunch of aluminum and nylon spacers and washers that fit M3 screws...they are cheap and will definitely come in handy when you need them.

joostin420

Premium Member!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 2,978

- Reaction score

- 6,218

- Location

- MA/NH

- Arrma RC's

- Fazon

- Kraton 8S

- Kraton 6s

- Outcast 6s

- Outcast 8s

- Senton 6s

- Typhon 6s

I didn’t use any spacers on either Kraton or senton builds. Used gka mount in Kraton and hr mount in senton. You should be able to see all how I use washers and nuts for straight link from servo horn to bell crank arm.

Krod877

Member

- Messages

- 18

- Reaction score

- 28

- Arrma RC's

- Senton 6s

Savox 1210sg and gpm mount and horn

Attachments

- Thread starter

- #13

I used the hot racing mount and servo arm/link on mine. The link without the rubber grommets was only a little crooked but with the rubber bushings and eyelets the link was too much of an angle. I may be removing the grommets for a direct mount if I get the servo clamps from Voltage or HR. The horn touches the body ever so slightly. We shal see.

GregMonahan

Fairly New Member

Please shed me some light on those body mounts with the knurled cap? I am sick as poop with those pin types, already........ A part number or a link would having me order them within minutes of getting the info. Thanks and some beautiful work shown in this thread.....damn.

Krod877

Member

- Messages

- 18

- Reaction score

- 28

- Arrma RC's

- Senton 6s

Gpm racingPlease shed me some light on those body mounts with the knurled cap? I am sick as poop with those pin types, already........ A part number or a link would having me order them within minutes of getting the info. Thanks and some beautiful work shown in this thread.....damn.

GregMonahan

Fairly New Member

Thanks sir.GregGpm racing

calabiyau

Active Member

- Messages

- 133

- Reaction score

- 112

- Arrma RC's

Very helpful thread. Just received the exact same thing as the poster (Savox 1210+HR mount++axial horn) and sort of had the same question. Because the wire is higher up the side of the Savox servo than the stock servo, the wires get very pinched getting them "below" the mount rim when you drop it into the mount. I was concerned about damaging the wires where they come out of the servo as it is very tight.

The pictures were helpful too, Thank You

The pictures were helpful too, Thank You

calabiyau

Active Member

- Messages

- 133

- Reaction score

- 112

- Arrma RC's

I used the hot racing mount and servo arm/link on mine. The link without the rubber grommets was only a little crooked but with the rubber bushings and eyelets the link was too much of an angle. I may be removing the grommets for a direct mount if I get the servo clamps from Voltage or HR. The horn touches the body ever so slightly. We shal see.

I could not get the Axial horn I bought with the Servo (amazon recommended) to work as it sits closer to the Servo than the stock horn and the screw will not clear the body when the horn turns across the body.

Ended up using stock horn and arm/link with a couple spacers since the link rides higher than with the stock servo

I’m using the stock link which is pretty thick. Might try the HR horn and link but you say your’s scrapes the top of the Servo too?

Attachments

Similar threads

- Replies

- 13

- Views

- 884