- Thread starter

- #21

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Senton Bash Break Fix Repeat

- Thread starter greatdividers

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

- Thread starter

- #22

Here we go again!

I've gone out bashing 3 times with it since the last update and it took until the 3rd go before something broke . I broke my other rear wheel axle. Fortunately I had the spare parts required to repair it. I was trying to mostly drive it on hard packed snow in this field but then I found some snow mounds aka jumps. It isn't really fast enough to get big air but I guess the cold isn't great for parts durability. Oh well, it was a blast. I'll be going again today but I'll try and avoid the jumps

. I broke my other rear wheel axle. Fortunately I had the spare parts required to repair it. I was trying to mostly drive it on hard packed snow in this field but then I found some snow mounds aka jumps. It isn't really fast enough to get big air but I guess the cold isn't great for parts durability. Oh well, it was a blast. I'll be going again today but I'll try and avoid the jumps

I've gone out bashing 3 times with it since the last update and it took until the 3rd go before something broke

Attachments

jondilly1974

Speed running apprentice, motor Slayer 🤘

Lifetime Premium!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 26,134

- Reaction score

- 38,839

- Location

- Toledo, OH

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Kraton EXB

- Senton 3s

- Typhon 6s

- Typhon 3s

Wow I would have thought something plastic would break before the metal axle ??Here we go again!

I've gone out bashing 3 times with it since the last update and it took until the 3rd go before something broke. I broke my other rear wheel axle. Fortunately I had the spare parts required to repair it. I was trying to mostly drive it on hard packed snow in this field but then I found some snow mounds aka jumps. It isn't really fast enough to get big air but I guess the cold isn't great for parts durability. Oh well, it was a blast. I'll be going again today but I'll try and avoid the jumps

- Thread starter

- #24

I know right! I've gone bashing a few times since and no more breakageWow I would have thought something plastic would break before the metal axle ??

The springs were too long for my rear shocks causing the rear suspension to be fully extended at rest. I took it upon myself to shorten and flatten the springs and it's sitting much better now. Handling is greatly improved too.

This week I will try and make progress on installing my bearing kit as well has the hd input gears. I ordered a kimbrough servo saver and that will likely be my last modification for this machine, excluding upgrading when breaking things.

Attachments

- Thread starter

- #25

Took lots of pictures this build session! My goal was to get new bearings, hd inputs, and possibly a new servo installed. The messy and crowded work area

Eww rust

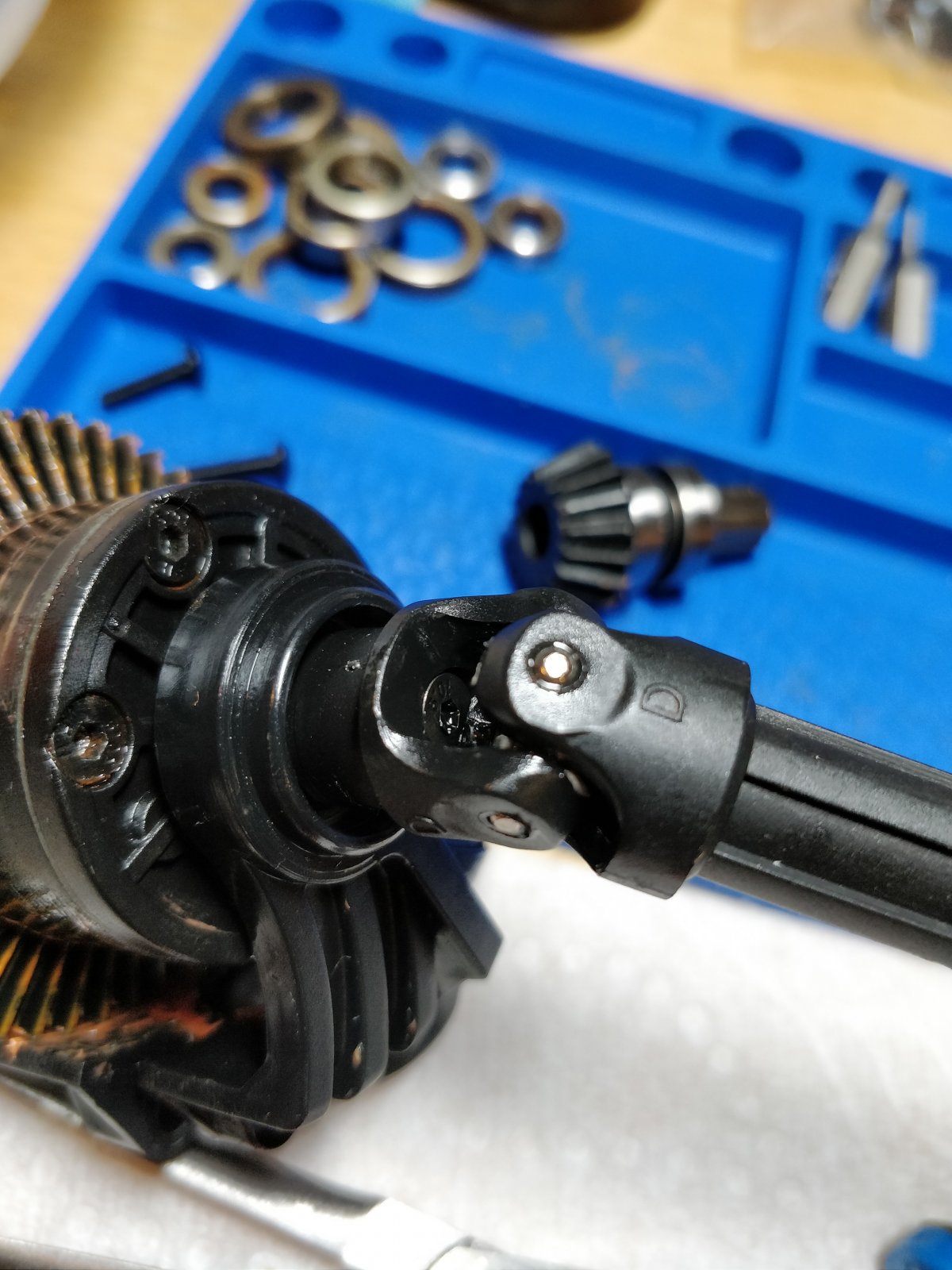

Got my way into a diff and found my stop point for the bearing install. I don'd have a tool that can reach though the driveshaft for this screw. HD input gear in the background

And by far the best RC-related purchase yet. This thing has saved me so much time and no more wrist cramps!

I finished up the bearings and decided to go for the servo install. Everything coming apart and back together was easy. Unfotunately, I believe there is something wrong with the servo I installed (savox 1210sg). I was able to adjust the trim and end points with it but it seems to be very loud when operating. It kind of makes a electronic shuddering sound, like it's moving back and forth really quickly. I'm going to do some youtubing to see if I can determine if it's bad or something else is going on. I'll post a video if I can't find anything.

Senton resting for now. I have the day off so will continue on with RC stuff . Working on my twin hammers next.

. Working on my twin hammers next.

Eww rust

Got my way into a diff and found my stop point for the bearing install. I don'd have a tool that can reach though the driveshaft for this screw. HD input gear in the background

And by far the best RC-related purchase yet. This thing has saved me so much time and no more wrist cramps!

I finished up the bearings and decided to go for the servo install. Everything coming apart and back together was easy. Unfotunately, I believe there is something wrong with the servo I installed (savox 1210sg). I was able to adjust the trim and end points with it but it seems to be very loud when operating. It kind of makes a electronic shuddering sound, like it's moving back and forth really quickly. I'm going to do some youtubing to see if I can determine if it's bad or something else is going on. I'll post a video if I can't find anything.

Senton resting for now. I have the day off so will continue on with RC stuff

jondilly1974

Speed running apprentice, motor Slayer 🤘

Lifetime Premium!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 26,134

- Reaction score

- 38,839

- Location

- Toledo, OH

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Kraton EXB

- Senton 3s

- Typhon 6s

- Typhon 3s

What's in the Milwaukee zipper case? I have those same bits too. ?Took lots of pictures this build session! My goal was to get new bearings, hd inputs, and possibly a new servo installed. The messy and crowded work area

View attachment 65067

Eww rust

View attachment 65068

Got my way into a diff and found my stop point for the bearing install. I don'd have a tool that can reach though the driveshaft for this screw. HD input gear in the background

View attachment 65069

And by far the best RC-related purchase yet. This thing has saved me so much time and no more wrist cramps!

View attachment 65070

I finished up the bearings and decided to go for the servo install. Everything coming apart and back together was easy. Unfotunately, I believe there is something wrong with the servo I installed (savox 1210sg). I was able to adjust the trim and end points with it but it seems to be very loud when operating. It kind of makes a electronic shuddering sound, like it's moving back and forth really quickly. I'm going to do some youtubing to see if I can determine if it's bad or something else is going on. I'll post a video if I can't find anything.

Senton resting for now. I have the day off so will continue on with RC stuff. Working on my twin hammers next.

View attachment 65071

- Thread starter

- #27

That is just the case for the electric driver. It should be inside the cardboard box but I was lazy lolWhat's in the Milwaukee zipper case? I have those same bits too. ?

So after some youtube searching on Savox servo noise I've determined it's normal for a digital servo to sound like this. Shows how much I have to learn still

jondilly1974

Speed running apprentice, motor Slayer 🤘

Lifetime Premium!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 26,134

- Reaction score

- 38,839

- Location

- Toledo, OH

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Kraton EXB

- Senton 3s

- Typhon 6s

- Typhon 3s

All my M12 tools came with a hard case. Never saw a zipper box like that before... ?That is just the case for the electric driver. It should be inside the cardboard box but I was lazy lol

So after some youtube searching on Savox servo noise I've determined it's normal for a digital servo to sound like this. Shows how much I have to learn still

- Thread starter

- #29

This may be the final form. It seems like I will be trimming the body as the wheels touch on compression. My concern now is I already wanted it to be faster and more powerful..... now with larger wheels it might be the opposite

Last edited:

- Thread starter

- #30

Took it out for about 10 minutes and was really impressed with the tires! The extra ground clearance and traction really made a noticeable difference in the snow. Took it off the same jump as always and..... broke a rear a-arm  . Maybe it's a sign that I shouldn't jump it in the winter but where is the fun in that! Looking at upgrading the a-arms now. It seems like everyone recommends RPM so will probably go with them. Now it's sidelined, again, until parts arrive.

. Maybe it's a sign that I shouldn't jump it in the winter but where is the fun in that! Looking at upgrading the a-arms now. It seems like everyone recommends RPM so will probably go with them. Now it's sidelined, again, until parts arrive.

I'll post some pictures off the carnage later after the rig dries off.

I'll post some pictures off the carnage later after the rig dries off.

- Thread starter

- #31

- Thread starter

- #32

Haven't updated this in a while! Lets go over what has happened in the last month.

I've been taking this thing out for a few packs every week. I've broken and replaced 3 camber links and one toe link, cracked the body, repaired the body, installed a full set of rpm a-arms, installed a mamba x with 3800kv sensored motor, 17T pinion, reinstalled the factory wheels and I broken my t-bone front bumper slightly.

It looks kind of bad with the trimmed body and factory wheels but I want to see if the big wheels were part of the reason my links keep breaking. Only one broke because of running into a pole. The rest were off "reasonable" jumps in the cold

My previous setup was 60A esc w/ 3300kv non-sensored. The upgrade to the castle system was definitely noticeable but I was expecting a bigger improvement. I'm thinking of getting a 21T pinion to try. Currently have 17, 18, 25T pinions at home for this motor. Alternatively I could try 3S but I don't have a battery and I don't think my drivetrain would like it much

I've been taking this thing out for a few packs every week. I've broken and replaced 3 camber links and one toe link, cracked the body, repaired the body, installed a full set of rpm a-arms, installed a mamba x with 3800kv sensored motor, 17T pinion, reinstalled the factory wheels and I broken my t-bone front bumper slightly.

It looks kind of bad with the trimmed body and factory wheels but I want to see if the big wheels were part of the reason my links keep breaking. Only one broke because of running into a pole. The rest were off "reasonable" jumps in the cold

My previous setup was 60A esc w/ 3300kv non-sensored. The upgrade to the castle system was definitely noticeable but I was expecting a bigger improvement. I'm thinking of getting a 21T pinion to try. Currently have 17, 18, 25T pinions at home for this motor. Alternatively I could try 3S but I don't have a battery and I don't think my drivetrain would like it much

Attachments

- Thread starter

- #33

Self isolating so more updates  . I ordered the aluminium GPM turnbuckles, steering assembly and cvd drive shafts. Probably won't get them for a while unfortunately.

. I ordered the aluminium GPM turnbuckles, steering assembly and cvd drive shafts. Probably won't get them for a while unfortunately.

Did a complete tear down of the diffs on the truck this morning. I originally rebuilt them with some grease, not oil, so they ran pretty much fully open. So took them apart, brake cleaned all the old grease away, replaced the bearings with fast eddys. The paper gaskets should have been replaced but I have no access to them without at least a weeks wait. So I put the thickest fluid in I had . 30k front and 50k rear.

. 30k front and 50k rear.

I'm curious how it will perform on snow and pavement. I think it's going to be pretty awful but we will find out after this pack finishes charging

Did a complete tear down of the diffs on the truck this morning. I originally rebuilt them with some grease, not oil, so they ran pretty much fully open. So took them apart, brake cleaned all the old grease away, replaced the bearings with fast eddys. The paper gaskets should have been replaced but I have no access to them without at least a weeks wait. So I put the thickest fluid in I had

I'm curious how it will perform on snow and pavement. I think it's going to be pretty awful but we will find out after this pack finishes charging

- Thread starter

- #34

Well the new diff fluids turned out great! It was a power sliding animal with the factory wheels and new diff fluid. So much fun  .

.

It seems like when I approach LVC with the mamba x and sensored castle motor it starts cogging at crawling speed. Can anyone chime in if this is normal or not? I'm assuming so because I have no abnormal noise or anything else when running it.

I found my driveshaft centre support bearing was seized after about 8 runs so I replaced it with a fast eddy bearing.

After this COVID stuff settles down I might look into upgrading the drivetrain for some 3S power

It seems like when I approach LVC with the mamba x and sensored castle motor it starts cogging at crawling speed. Can anyone chime in if this is normal or not? I'm assuming so because I have no abnormal noise or anything else when running it.

I found my driveshaft centre support bearing was seized after about 8 runs so I replaced it with a fast eddy bearing.

After this COVID stuff settles down I might look into upgrading the drivetrain for some 3S power