- Thread starter

- #41

Ahhh..

Big daddy (gotnitro talks about himself in the 3rd person and sometimes in the 4th person) is gunna make this 4040 fit baby!!

First pic, I shimmed out the motor mount a couple MM's

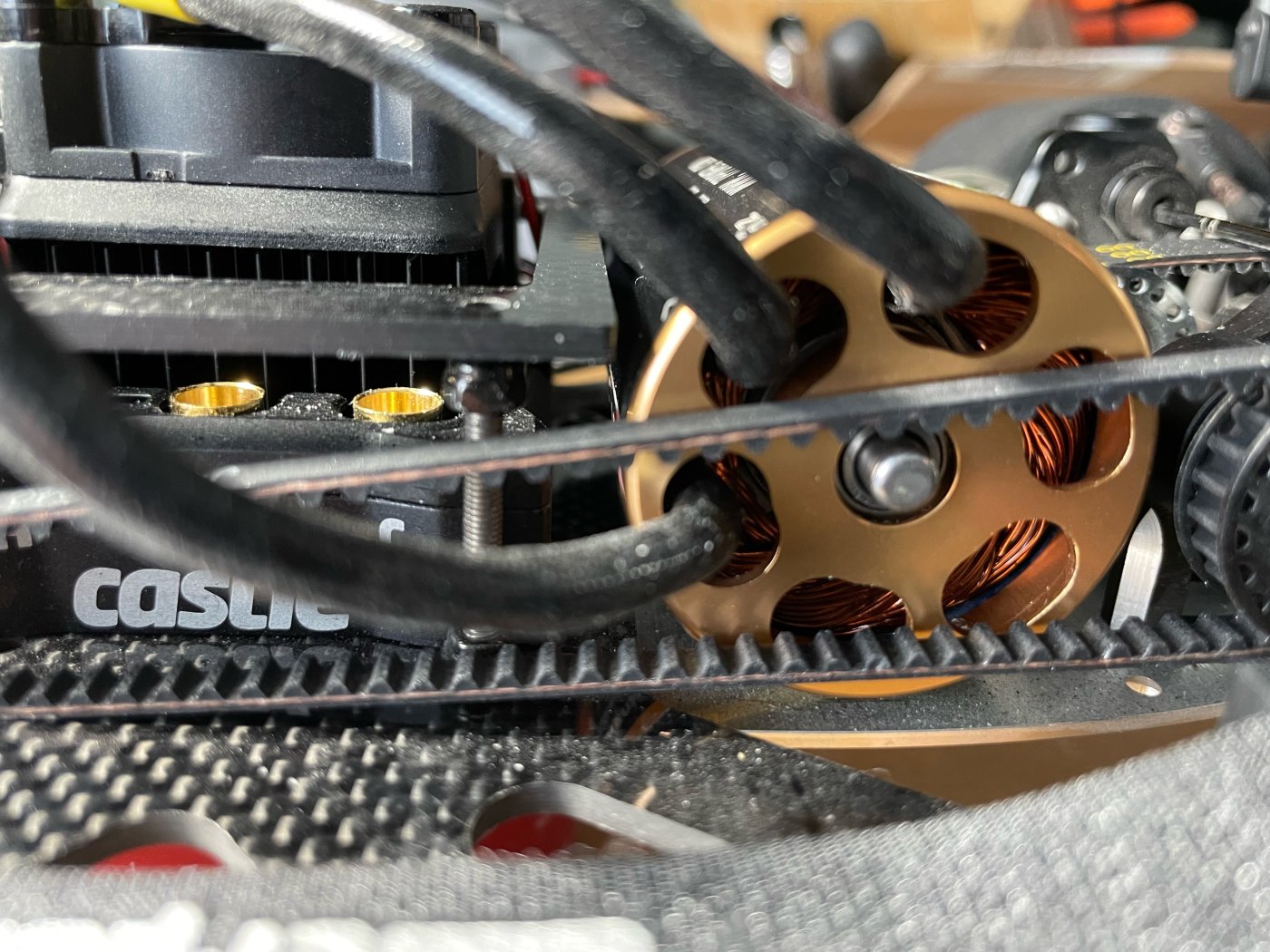

Second pic is belt clearance. You can see, it makes it buy the back of the can with 1/2 of a C-hair.

3rd pic, one of the motor wires HAS to go between the belt. Only way to make it fit.

It's tight how I like it with a little bit of possible danger. Sign me up!

Big daddy (gotnitro talks about himself in the 3rd person and sometimes in the 4th person) is gunna make this 4040 fit baby!!

First pic, I shimmed out the motor mount a couple MM's

Second pic is belt clearance. You can see, it makes it buy the back of the can with 1/2 of a C-hair.

3rd pic, one of the motor wires HAS to go between the belt. Only way to make it fit.

It's tight how I like it with a little bit of possible danger. Sign me up!